Bugles 3d extrusion Bugles 3d extrusion snack food processing machinery processing machinery

1. Description:

The snacks are extruded in single screw extruder or twin screw extruder , by rotary cutting device and different dies , it is able to make different shapes

The snack pellets do not need drying process , it can be fried directly after coming out from the sinlge screw extruder or twin scrrew extruder

The taste of this direct fried snacks are cruchy and tasty

Equip with Pattern pressing machine,compound shaping machine,frying machine ,the twin screw extruder can produce burgles,pillow,goldfish and other 3D fried snacks food .

2. Capacity: 150kg/h,260kg/h

3. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

4. Flow chart:Mixing system---Extrusion system---- -Frying system----Flavoring system---Packing system

1.Mixer : mix raw material equally according to the recipe

2.Spiral Conveyor : take the raw material to the extruder

3.Extruder : cook and extrude the raw material with certain pressure and temperature to make different puffed snacks

4.Vibrator : vibrate the snacks to avoid them stick together

5.Pattern presser : emboss pattern on the snack sheets

6.Compound cutter : press 2 pieces snack sheets together and cut them into shape by the shaping roller

7.Fryer: fry the snacks to make them puffed and crispy

8.Flavoring machine : flavor the snacks with different seasonings

The material of automatic fried snacks food processing line price

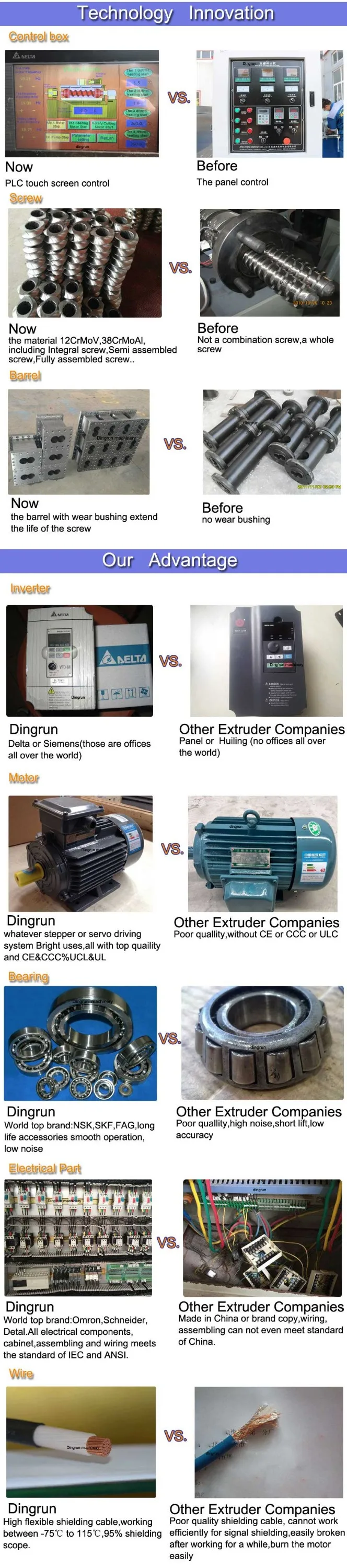

Our Advantage

Our Advantage Our Company

Our Company

Our Service

Our Service1)Free management of equipments' long distance shipping;

2)Provide factory layout according to your factory size in advance;

3)Provide the basic formula;

4)Inspect the machine before leaving the factory;

5)Oversea installation and commissioning the equipment;

6)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

7)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

8)Provide English Version of Installation/Operation/Service/Maintenance Manual.

Packing & Delivery

Packing & Delivery1. Inside package is plastic film, outside is wooden or plywood case, or fumigation package with

certificate, (based on the customers' need).

2. Ship, train, express or upon clients' demands.

FAQ

FAQQ: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer’s factory for 7-14 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Ms. Amy

Wechat/whatsapp/cell: +86 Bugles 3d extrusion snack food processing machinery

Email: amy at Bugles 3d extrusion snack food processing machineryjixie.com

Web: en.cnBugles 3d extrusion snack food processing machineryjixie.com