potato chips corn snack manufacturer machine

1.Description:

Corn puffs potato chips corn snack manufacturer machine machine adopts advanced extruding technique which can extrude two kinds of products

with different textures and tastes out of doublescrew extruder at the same time. This line uses advanced

extruding technology, through changing moulds and production technics to produce many kinds of popular

potato chips corn snack manufacturer machine in the market, such as rolls, crispy stick, fragrant chicken, etc.

2. Raw materials: adopts corn, rice, wheat, oat, barley etc as ingredients

3. Products: Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart

shape by adjusting the mould in the extruder

4. Capacity: 150kg/h, 240kg/h, 500kg/h

5. Flow chart: Mixing system---Extrusion system---- -Drying system----Flavoring system--- packing system

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers'

Local voltage according to different countries

7. Machines Materials: All the machines are made by stainless steel

8.Corn snacks food processing line Technical Parameters

Model | Installed power | Real power | Output | Dimension |

ZH65 | 70kw | 40kw | 100-150kg/h | 22000x1200x2200mm |

ZH70 | 90kw | 50kw | 200-240kg/h | 25000x1500x2200mm |

ZH85 | 120kw | 100kw | 400-500kg/h | 30000x3500x4300mm |

ZH90 | 135kw | 100kw | 800-1000kg/h | 30000x3500x4300mm |

ZH115 | 165kw | 115kw | 1000-2000kg/h | 30000x3500x4300mm |

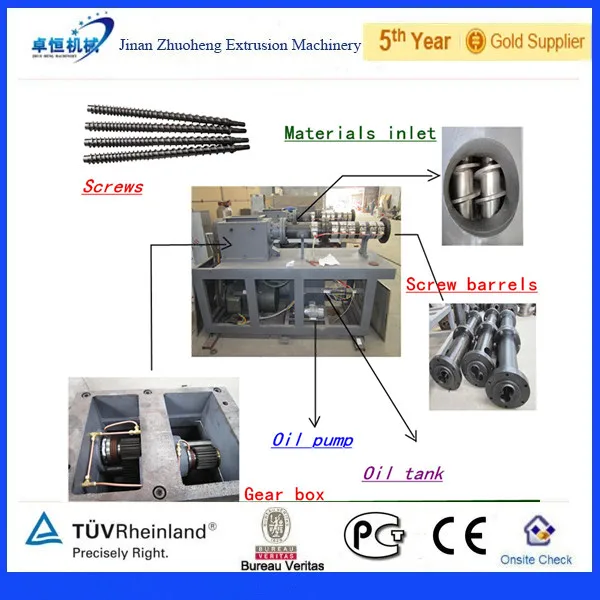

9.The features of thee corn snacks food processing line

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it as good

selfcleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. It adopts speedadjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin

screw feeding machine guarantees stable materials feeding in the whole food process.

3.The gearbox has automatic lubrication function, with extends gear life.

4. Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely.

5. Barrel with watercooled circulation, it makes extruder can be used not only for corn/rice, also for wheat flour/starch which a

re raw materials with high viscosity. Through different moisture-extrusion temperature ratio, it can make whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.