100% factory direct sales, look forward to building cooperate with you wholeheartedly!

Production process

Mixer → Screw conveyor → Extruder → Conveyor → Oven → Cooling → Packaging

| Model | Installed power | Real power | Output | Dimension |

| ZH65 | 35 kw | 22kw | 150kg/h | 39000x1200x2200mm |

| ZH70 | 50kw | 37kw | 250kg/h | 41000x1500x2200mm |

| ZH85 | 110kw | 75kw | 500kg/h | 43000x3500x4300mm |

| ZH95 | 151kw | 110kw | 1ton/h | 4700x1900x4800mm |

| ZH135 | 425kw | 335kw | 3ton/h | 5200*2000*4800mm |

| ZH*** | ***kw | **kw | **ton/h | ****** |

Technical Features of Floating Fish Feed Extruder

1. This extruder equipment adopts the auto-controlling speed feeding tool to produce the feed material evenly.

2. High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

3. The cutting knife adopts the frequency controlling speed in order to change the material size.

4. The floating time can be controlled by the puffing degree adjustment.

5. Auto-temperature control system makes the temperature controlling more direct viewing and the parameter more precise.

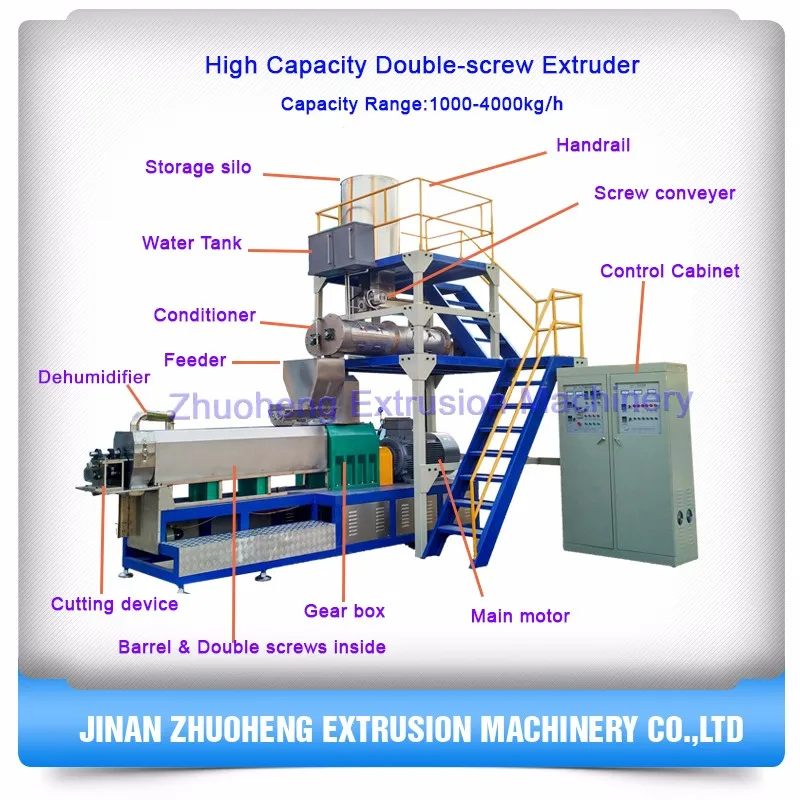

Twin-Screw Extruders

In order to create a design with greater operating flexibility and with greater operational control, twinscrew machines were developed. Twin-screw extruders can be co-rotating, counter-rotating, intermeshing or non-intermeshing in terms of basic designs. Co-rotating, intermeshing screw designs have dominated that scene as far as these extruders are concerned. This is because of relative ease of design and manufacture compared to counter-rotating designs.The screw design of twin-screw extruders can

affect operating efficiency and machine capability. Screw components in the feed section of the barrel can be single, double or even triple flight arrangements. With more flights intertwined on the shaft, the conveying capacity of the screw is reduced but the residence time distribution is lower. This promotes a first-in, first-out movement of the extrudate. However, double- and triple flighted screws produce more shear across the screw channel and therefore, improved processing uniformity.

Advantages of Floating Fish Feed Machine

1) This fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal.

2) Advanced technology and humanized design ensures easy operation and reliable performance.

3) High efficiency, low power consumption

4) Screw sleeve of this small fish food extruder adopts enchase alloy steel strip structure, which guarantees long service life.

5) Different moulds can be chosen to make pellets with different diameters and shapes.

6)Capacity:0.1-10T/H

Twin-screw Extruder

Twin-screw Extruder Unit is the high standard and professional extrusion machinery unit. It’s consist of bucket elevator, Storage Silo, material conveyor, conditioner, feeder, extruder, electric controller and operation platform. The extruder includes drive system, extrusion system, cutting system, heating system, lubricating system and extraction steam system.Conditioner is designed as the advanced technology biaxial differential modulator.

It can higher the materials temperature, make flour materials softer, lower the materials’ friction . Thus reducing the extrusion power consumption, increasing the output, improving the stability of the extruder operation, prolonging life of t the whole extruder unit. To ensure the materials completely curing and pasting, extruder adopted double screw synthetic rotary extrusion technology( double screw diameter ratio is 19.58)The double screw of the extruder is designed as the 38CrMoAl modular sectional screw, easy to adjust the different screw functional sections. Then it can be accurate to adjust the quality of different products. The screw has higher wear resistance dog/cat/fish/shrimp food extruder machine/animal food extruder service life with nitrogen treatment.

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Related Products

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Contact

Ms. dog/cat/fish/shrimp food extruder machine/animal food extruder Huang

dog/cat/fish/shrimp food extruder machine/animal food extruder

dog/cat/fish/shrimp food extruder machine/animal food extruder 3170339976

dog/cat/fish/shrimp food extruder machine/animal food extruder 15168894279

dog/cat/fish/shrimp food extruder machine/animal food extruder: zhjx-01@ jnzhjx.com

Mobile Phone: +86 15168894279

WhatsApp/Viber/Imo/dog/cat/fish/shrimp food extruder machine/animal food extruder +86 15168894279