Fried Nik Naks/Kurkure Production Line

Product DescriptionDescription of Fried Nik Naks/Kurkure Production Line

Fried Nik Naks/Kurkure Production Line is adopt corn grist (maize granule) as raw material , through rotary head extruder to extrud out twist corn curls (the length can be decide by customer favor), after this it will be processed with dryer or fryer and flavored . Then various taste of crunchy cheetos/nik nak/corn curls sell in the market.

1. Raw Material : Corn Grist

2. Final Products: Corn Stick ,Twist Stick

3. Capacity : 150Kg/h ,250Kg/h

4. Voltage: Normally 380V/50Hz,can be made accord with customer requirements

5. Configuration : Can according customer requirments to adjust ,such as the inverter brand ,motor brand , electronic parts brand ,machine cover.

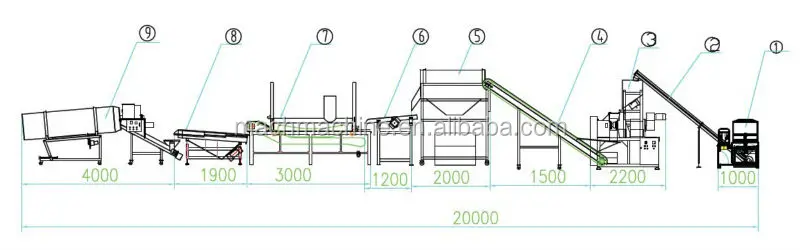

Product Flow chart

Product flow chart of Fried Nik Naks/Kurkure Production Line

Mixer---Screw Conveyor---Rotary Head Extruder---Hoister---Cooling and Separate Roller---Vibrant Feeder---Continuous Fryer---Vibrant Deoil Machine---Flavoring System---Packing System

Technical parameters

Technical Parameters of Fried Nik Naks/Kurkure Production Line

Model | Installed Power | Power Consumption | Output | Dimension |

MHXJAF Fried Kurkures Line | 96Kw | 62Kw | 100-150kg/h | 1700*1100*2500mm |

MHXJBF Fried Kurkures Line | 98Kw | 63Kw | 200-250kg/h | 1730*1200*2600mm |

sample view

Sample Room

Packaging & Shipping

Fumigation Free Ploywood or 20'GP 40'HQ

Service And Turnkey Solution

1. Provide project design and planning .

2. Provide debugging Machine and training

3. Provide basic formula and techniques

4. Provide 1 year guarantee for machine and long-time technic service

Contact Information

Contact Us

Fried Nik Naks/Kurkure Production Line Welcome Customer To Vist Us