Kurkure Making Machine

Product Description

Description of Kurkure Making Machine

Kurkure Cheetos Nik Naks are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes. The cutting knives can cut into required lengths. The Kurkure Cheetos Nik Naks are fried in cooking oil or toasted in oven and then cooled before flavoring. Seasoning is sprayed on the surface to achieve different favorable tastes. Due to the delicious flavors and nutrition, it is quite popular with consumers

1. Raw materials: Corn Grits

2. Products: Kurkure Cheetos Niknak with Different Tastes

3. Capacity: 150Kg/h ,250Kg/h

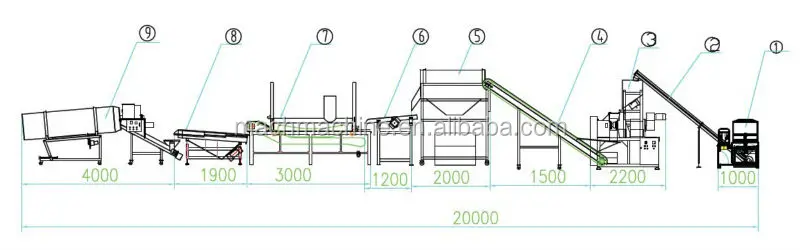

4. Flow Chart: Mixing—Extrusion—Separating—Frying or Baking— Flavoring

5. Voltage: Three phases: Three phases: 380V /415V /440V /220V, we can make it according to customers' Local voltage according to different countries

6. Machines Materials: All the machines are made by food grade stainless steel.

Production Flow

Flow Chart of Kurkure Making Machine

Sample View

Sample Room

Hot Selling Products

Hot Selling Food Process Machinery | |

1 | Potato Chips Process Machinery |

2 | Soya Nuggets Process Machinery |

3 | Doritos Chips Process Machinery |

4 | Breakfast Cereal Corn Flakes Process Machinery |

5 | Pet Dog Fish Feed Process Machinery |

6 | Fried Nik Nak Cheetos Kurkures Process Machinery |

7 | Corn Puff Snacks Process Machinery |

8 | Peanut Butter Process Machinery |

9 | Extruded Wheat Flour Snacks Process Machinery |

10 | Nutrition Rice Process Machinery |

11 | Instant Grain Powder Process Machinery |

12 | Bread Crumb Process Machinery |

13 | Instant Noodle Process Machinery |

14 | Dough Snacks Process Machinery |

15 | Baked Cheetos Corn Curl Process Machinery |

16 | Dog Cat fish feed Process Machinery |

Packaging & Shipping

Fumigation Free Ploywood or 20'GP 40'HQ

Our Services

Service And Turnkey Solution

A .Consultation service before, during, and after sales.

B. Project planning and design service.

C. Debugging of equipment until everything is functional .

D. Management of equipments' long distance shipping from seller's factory to the Destination Port .

E.Training and Guiding Buyer about equipment maintenance and operating personally.

F. New production techniques and formulas for basic Shaping.

G. Provide 1 year complete warranty and life-time maintenance service.

H. Provide Long-time Technic Service and After Service

Contact Information

Contact Us

Kurkure Making Machine

Welcome Customer To Vist Us and Comment On Our Service and Technical