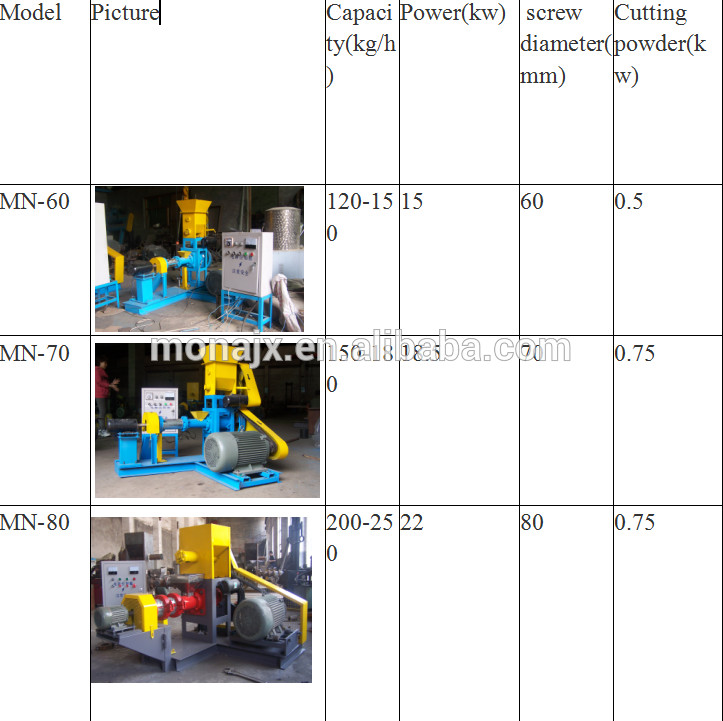

Product manual

Advanced pelletizing structure, using the cutting tool axis positioning spring together

form

stepless, the material can be cut to the desired length products. Novel design, unique,

simple structure, easy to install and easy to dismantle and easy to unload, easy to operate.

38 chrome molybdenum screw and screw with special wear-resistant high temperature

and

humidity of the material aluminum, first quenched and then heat-treated molding,

has the

advantage of wear resistance and long life. It offers a unique pressurized die means

to

ensure that the quantity and quality of feed; electric heating device improve the feed

expansion rate, NSK spindle bearings used in combination and Sweden SKF bearings,

to ensure Extruder safe and reliable. The main motor of high quality Y series

three-phase

motor to ensure strong power; with the main gear motor, ensuring plenty of power.

Production of extruded feed floating particles can float on the water for at least 12 hours will

not bubble casual, fish and poultry eating digestible, can easily observe artificial frog fish

appetite, no waste feed, not water pollution. Material high temperature and pressure

effective in killing E. coli, salmonella and other harmful bacteria to ensure that feed hygiene

is conducive to the absorption of protein denaturation and starch paste, fish and poultry is

easy to absorb. Commonly used in extruded, floating fish feed ratio of powdered or

granulated feed feed savings of 8% -15%. Production cooked sinking aquatic products,

livestock feed particles, can eliminate most of the material containing toxins and

anti-nutritional factors antitrypsin and urease, which is conducive to digestion and

absorption of the animals, improve digestion and utilization of nutrients.

1. Floating fish feed pellet machine Advantages:

2. With different moulds, the machine can produce different diameter food, from 0.9mm to 10

mm. The food can meet different stage fish. The food can be floating 24hours

3. It can produce different shapes feed for fish, dog, cat etc.

4.Through the pretreatment of the feed, it can reduce loss of nutrition and advance the protein

ratio.So the feed will be digested easily by animals.

2. Raw Material:

Corn flour,wheat flour,soya flakes meal,wheat bran,bone meal,fish meal,meat meal,Miscellaneous meal, bone meal, soybean meal, fish meal, cereals etc.

Function:

Ornamental fish, pets, poultry, aquatic products, livestock

Complete flow chart for fish feeding machine

Raw material preprocessing--crushing--mixing--extruder--cooler--dryer--flavoring

.

Detailed Images

Detailed Images

Finished product

Finished product

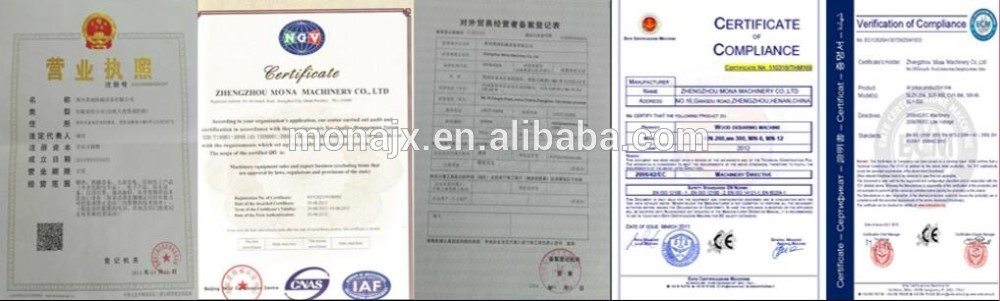

Packing & Delivery

Packing & Delivery

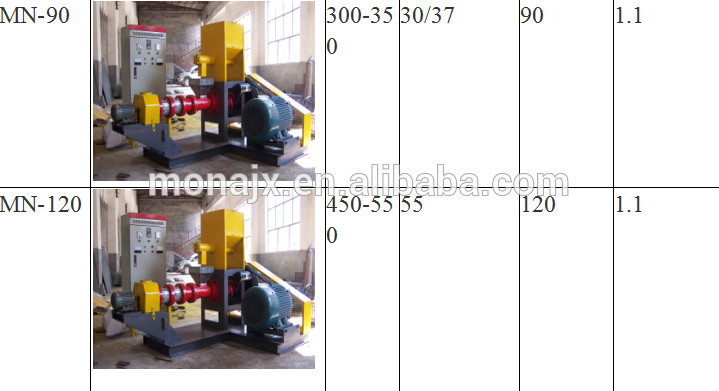

Certifications

Certifications

Related Products

Related Products

fish food pellet extruder machine

91.8% Response Rate

CE ISO Ring Die Biomass Wood Pellet Mill/ Wood Pellet Making Machine Price/ Sawdust Wood Pellet Machine Price

91.8% Response Rate

CE certificate wood pellet machine and feed pellet machine 0086-18037101692

91.8% Response Rate