Screw Self-cleaning 3D Snack Pellet Machinery For Fried Snacks , Pellets Extruding Machine

Specifications

-Food grade stainless steel

-Famous brand electric parts

-Screw self-cleaning

-CE, ISO certificate

-Automatic Line

Single Screw Extruder 3D 2D Fry Snack Pellets Extruding Machine

Pellets Extruding Machine,

Fry Snack Machine,

3D Pellets Machine

I. Description

3d pellet machine is designed for making the 3 D pellets/2 D pellet snacks by single screw extruder machine. Raw materials can be potato starch, corn starch, wheat starch, wheat flour, cassava starch etc. Through the extruder cooking, the snacks can be shaped in two layer piece, and than go to the compound shaper to get the 3D shapes. After change the cutter roller on the compound shaper, that can get different shape. like Triangle,Ellipsel, Battledore, Hexagonal, Rectangle,Christmas tree and so on. After drying and frying, flavoring with the flavor powder can get delicious snacks food.

After drying the pellet need frying to get expanded. This line is characterized by unique technique, rational configuration, high automation and stable performance. It can finish steaming, extrusion and shaping in one step without boiler.the products have similar shapes to the real one and taste crispy and delicious after fried.

1. Raw materials: Potato Starch, Corn Starch , Wheat Flour, Cassava Starch etc.

2. Products: By changing the shaping machine, we can produce 3D pellet, waved chips, potato chips, shrimp chips and so on.

3. Capacity: 100 KG/H

4. Flow Chart: Mixing —Extrusion —Shaping —Drying —Frying —Flavoring

5. Voltage : Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries.

6. Machines Materials: All the machines are made by food grade stainless steel.

7. Technical Parameters

Model | Installed Power | Power Consumption | Output | Size((L×W× H)) |

DP100 | 117kw | 82kw | 100kg/h | 27000x2000x2000mm |

DP 75 | 159kw | 111kw | 250-300kg/h | 30000×2000×2000mm |

2- Flow chart

1. Flour Mixer

2. Screw conveyor

3. Single screw extruder

4. Pulling and cutting machine

5. High Hoister

6. Drying machine

7. Feeding conveyor

8.Continuous fryer

9. Double Drum Flavoring Machine

3- Why You Must Choose Us

1. The Screw is made of durable hard alloy-38CrMoAl, with quite long using life.

2. Feeding Hopper uses Two grades mixing design which allows high feed speed and also avoid any block in raw materials.

3. Radiating Windows design ensure the thermal heat caused by machine discharge easily to

extend the machine using life.

4. 3D Snack Pellet Machinery(China) motors are used, ensure the excellent performance of machines.

5. Cooper Pipes used for cooling cylinder, they are quite durable than plastic rubber pipes.

6. Food Grade stainless steel made Cutter cover meet strict food process safety requirements.

List of Machines :

Sr. No. | Machine | Application / Use |

1 | Flour Mixer for pellet snacks production | To properly mix raw materials |

2 | Single Screw Extruder for pellet snacks production | To form pellet snacks under controlled pressure and temperature by the extrusion process in required shape and size by using different mould |

3 | Pulling & Cutting Machine for pellet snacks production | To give proper required shape to extruded snacks, if needed |

4 | Drying Machine for pellet snacks production | To dry extruded pellet snacks by removing extra moisture under high temperature and make it suitable for final packing |

5 | Automatic Pouch Packing Machine for pellet snacks production | To automatically pack finished snacks pellets in heat sealable laminated sachets and bags |

| DP100 Pellet Chips Processing Line | DP100 Macaroni Processing Line | |

| Installed capacity | 120KVA | 99KVA |

| Power | 83Kw | 69Kw |

| Output | 100-120kg/h | 100-120kg/h |

| Dimension | 18×2.5×2.5m | 25×2.5×3m |

Strong Fumigation-Free Case or 20'GP or 40'HQ

4- We Provide Satisfied Service & Turnkey Solution

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service.

Company InformationWho We Are

We are located in the famous industry city-Jinan city, capital of Shandong Province.

We are professional manufacturer of food extruder and mainly deal with the manufacture, research and

development of the inflating food machine. According to the clients’ different requirements, we could offer

the whole complete processing line for all kinds of expanded snacks, corn flakes, nutrition powder, and pet

food and so on. Our technical assistance will help clients produce high quality products all the time.

As a 3D Snack Pellet Machinery manufacturer of inflating food machinery, we are selling and marketing the machines to many countries in the world. We keep improving our machines and upgrading techniques to satisfy the requirements of all the clients. Depending on our rich experience and professional experts on the extruded food industry,we could offer the most suitable and complete program to assure that your investment will get biggest profit.

FAQ

1.What’s your payment terms?

Our payment terms is30% T/T as down payment, 70% by irrevocable L/C at sight or T/T before delivering

2. What’s your Guarantee?

We provide 1 year complete Guarantee and life-time maintenance service

3. How about the installation?

We will dispatch our engineers to your factory to guide you installation and commissioning work and training your operator.

4. I want to do many shapes and many tastes. Is it ok?

The shapes depends on the dies, we can design the dies according to your special request.

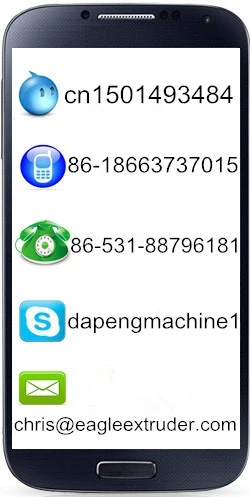

Contact Information:

If you have any needs or inquiries, please feel free to contact us!