Our Hot Products

Crispy Extruded Fry Wheat Corn Flour Pellet 3D Snacks production line

Product Description1) Introduction of Crispy Extruded Fry Wheat Corn Flour Pellet 3D Snacks production line

This process line is newly designed and produced with foreign advanced technology. It has been improved the disadvantages of import equipment such as large investment and high production cost.This line adopts corn starch, wheat flour, potato starch as material to produce burgles, potato food and many other 3d-shape compound extrusion food. With same functions, its price is only one tenth of that of import equipment. It is the best investment choice for large or medium-sized enterprises.

v 1. Raw materials: Potato Starch, Corn Starch , Wheat Flour, Cassava Starch etc.

v 2.Products: By changing the shaping machine, we can produce 3D pellet, waved chips, potato chips, shrimp chips and so on.

v 3. Capacity: 80-100kg/h, 250-300kg/h

v 4. Flow Chart: Mixing —Extrusion —Shaping —Drying —Frying —Flavoring

v 5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' loc al voltage of different countries.

v 6. Machines Materials: All the machines are made by food grade stainless steel.

2)technical parameters of Crispy Extruded Fry Wheat Corn Flour Pellet 3D Snacks production line

Model | Installation power | Consumption power | Capacity | Dimension (MM) |

ZH3D-90 | 117 kw | 82 kw | 70kg/h | 29000*1200*2000 |

ZH3D-130 | 154 kw | 108kw | 120kg/h | 24000*1800*2600 |

ZH3D-75 | 207 kw | 187kw | 250kg/h | 28900*2100*3000 |

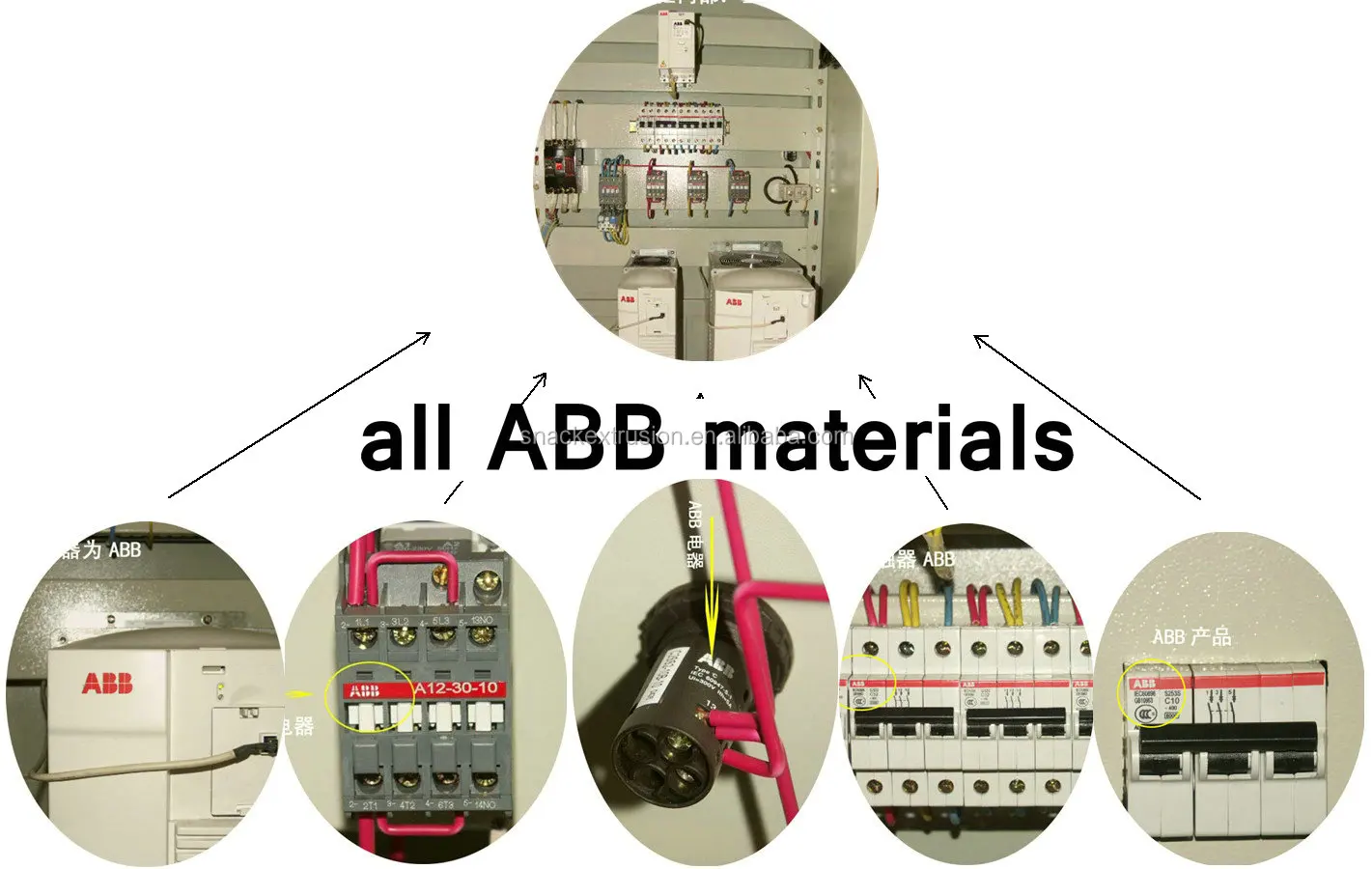

3)Details and parts of Crispy Extruded Fry Wheat Corn Flour Pellet 3D Snacks production line

4)pictures of Crispy Extruded Fry Wheat Corn Flour Pellet 3D Snacks production line

5)samples of Crispy Extruded Fry Wheat Corn Flour Pellet 3D Snacks production line

We provide the following service free of charge

1. provide optimized and advantage solution for customer

2. service on raw materials, flavor select

3. workshop , water, gas, electricity design for customer

4. management of shipment

5. training of equipment maintenance and operating work

6. provide new production techniques and formulas

7. Provide maintenance service within 1 year complete warrantee and lifetime

8 .2 technician will be sent to customer factory after shippment for installation

Packaging & ShippingWith full wooden package in container.Packing shall ensure the safety of Goods during its transportation and loading by Seller and unloading in the country of Buyer