fried bugles snack machine

kurkure cheetos machine

2d&3d pellet snack machine

Product Descriptionintroduction of flour tortilla chips making machine nacho making extruder

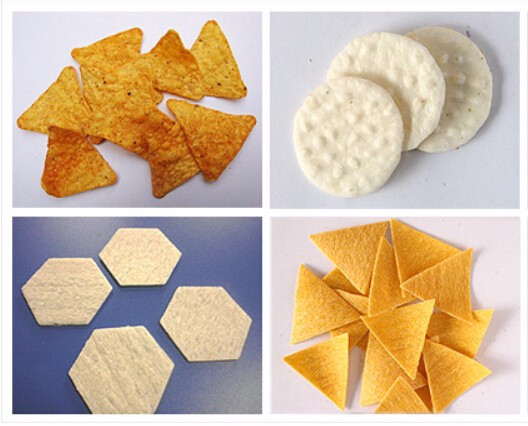

Doritos,Tortilla,Nachos, Corn chips‘ main raw material are using corn powder, the mixture is heated under pressure, and then extruded through a die, then use the shaper to make it, the texture of the snack is formed as a result of contact with hot air, causing steam in the mixture to expand and creating its characteristic texture. After frying, the product is then tumbled with the desired flavor components.

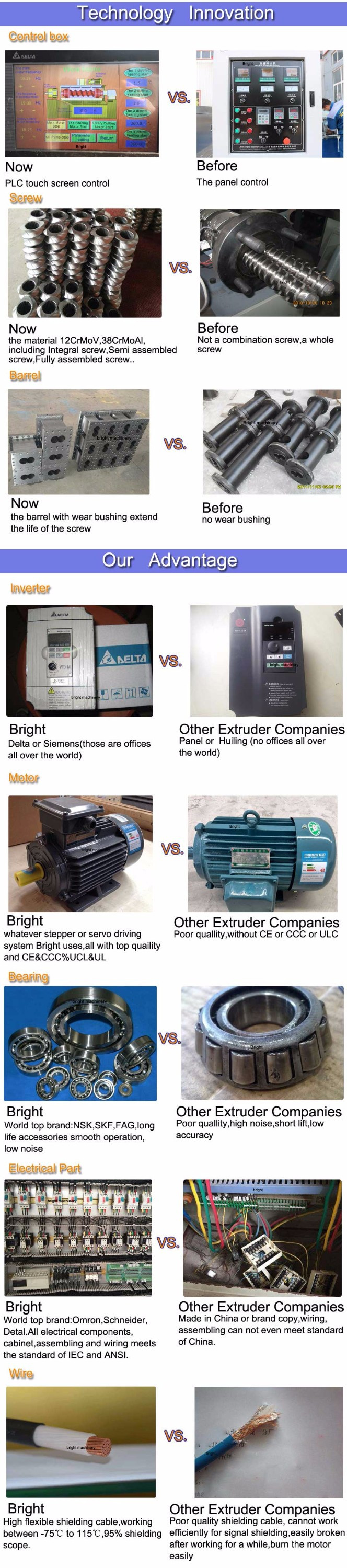

Main Features

1) Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning

ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2)Adopting speedadjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3)Gearbox with automatic lubrication function, extending gear life.

4) World famous brand flour tortilla chips making machine nacho making extruder main motor, guaranteeing good quality

5)Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

6)Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

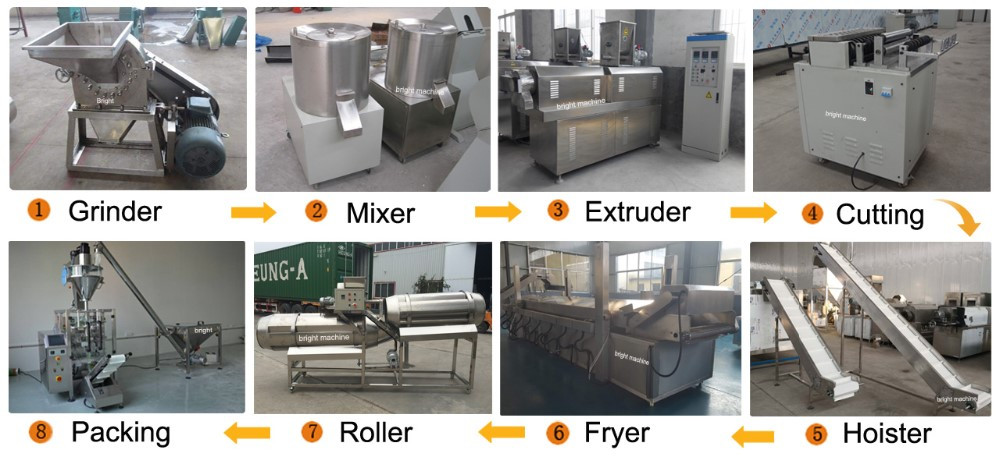

Flow chart :

grinding→mixing→extruding→drying→flavoring→cooling→packaging

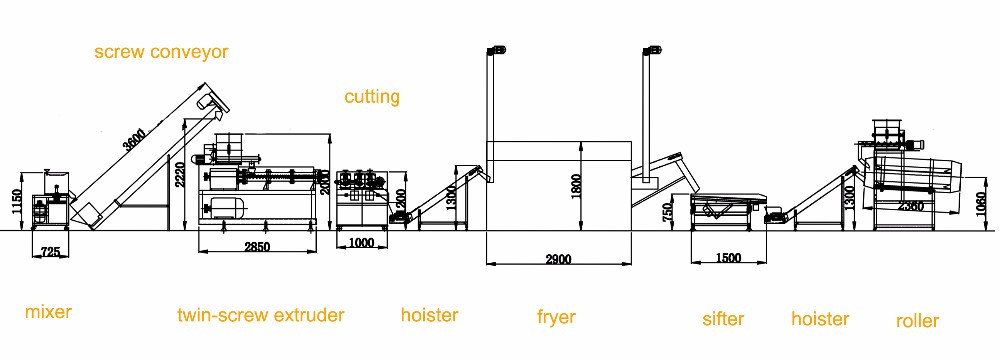

Flow chart diagram:

Our engineer could design the layout drawing according to your dimension of the factory for the fish feed machines

Machine parameters:

| Modle | Installed Power | Power Consumption | Throughput | Dimension(mm) |

| 65 Processing Line | 45kw | 30kw | 150~200kg/h | 18800x4500x2400mm |

| 75 Processing Line | 80kw | 50kw | 250~350kg/h | 26000x5000x3500mm |

Raw material:

Corn starch/Corn powder

Sample of flour tortilla chips making machine nacho making extruder :

Equipment list in the flour tortilla chips making machine nacho making extruder production line:

mixer→screw conveyor→twin screw extruder→cutting→hoister→fryer→flavoring drum→cooling machine→packing machine

1)mixer of flour tortilla chips making machine nacho making extruder

| Name | Mixer |

| Usage | To mix the raw materials evenly, fast speed, no leakage. |

| Type | including Single axle and double shaft mixer |

| Motor | 3kw, 4kw, 7.5kw etc. |

| Capacity | 20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc. |

| Material | stainless steel, carbon steel |

2)extruder of flour tortilla chips making machine nacho making extruder

| Name | Twin screw extruder(wet type/dry type) |

| Usage | To extrude the raw materials and make them to the required shape and size of the food pellets by mould |

| model | DSE65, 70, 75, 90, 95, 120, 135 |

| Motor | 22kw, 30kw, 55kw, 75kw, 90kw, 110kw etc. |

| Capacity | 100kg/h to 10 ton/h |

| Material | Screw materials 38CrMoAl stainless steel, carbon steel |

2)extruder of flour tortilla chips making machine nacho making extruder

| Name | cutting machine |

| Usage | Embossed plastic for flour tortilla chips making machine nacho making extruder |

| model | DSE |

| Motor | 0.75kw, 1.5kw |

| Capacity | 100kg/h-500kg/h |

| Material | stainless steel, carbon steel |

3)oven of flour tortilla chips making machine nacho making extruder

| Name | Continuous Fryer |

| Usage | Electric Belt and Upper Cover Lifting Setting .advantage of continuous production |

| Type | electrical, steam, gas fired, diesel fired heating type |

| Motor | KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc. |

| Capacity | 100kg/h to 10 ton/h |

| Material | stainless steel |

4)flavoring of flour tortilla chips making machine nacho making extruder

| Name | Flavoring machine |

| Usage | To mix the oil and flavors on the surface of the fish feed |

| Type | single and double flavoring drum |

| Motor | 0.75kw |

| Capacity | 100kg/h to 10 ton/h |

| Material | stainless steel |

5)packaging of flour tortilla chips making machine nacho making extruder

| Name | Packaging machine |

| Usage | To pack the flour tortilla chips making machine nacho making extruder with required weight |

| Flowing Process | Manual Bag placing→Automatic filling→Automatic weighing→ Automatic bag conveyor→Automatic bag sewing or heat sealing |

| Weight range | 1-5kg/bag, 5-25kg/bag, 25-50kg/bag |

| Material | stainless steel, carbon steel |

| Type | Automatic |

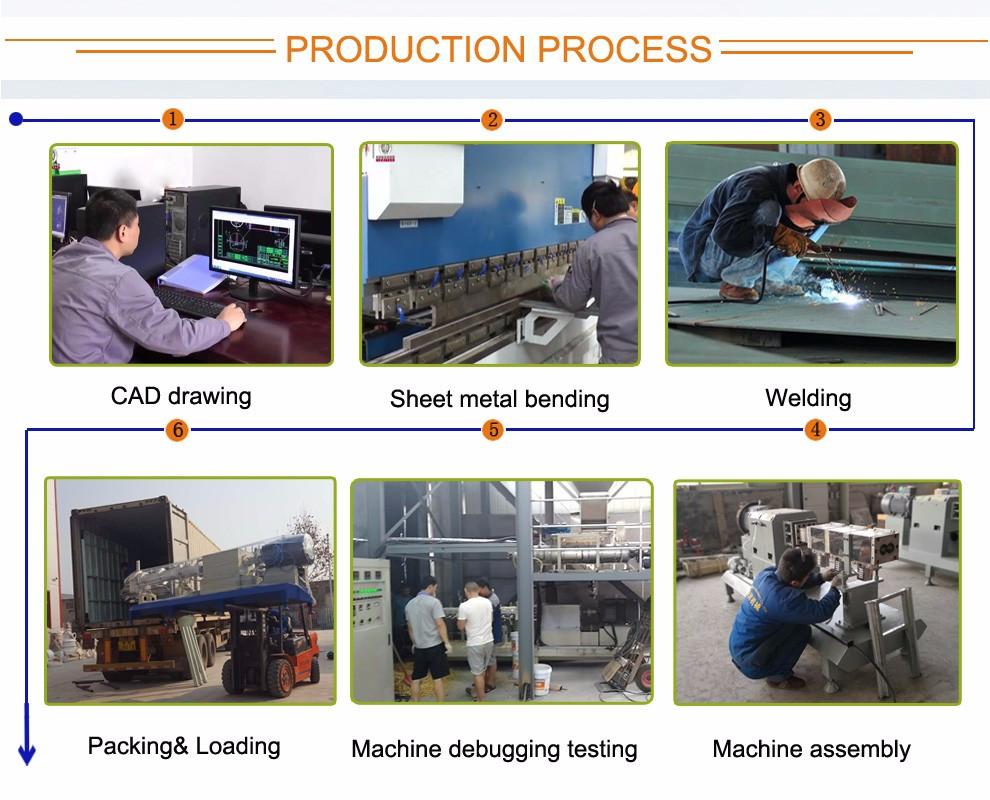

Bright company is in strict accordance with the industrial standards for cutting, bending, welding, strict

control of process quality, check whether the machine is qualified before delivery, to ensure that every machine for the customer is qualified artware selected carefully by Bright company.

Why choose us

Why choose us  Our Service

Our Service 1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

Company&Customer

Company&Customer

FAQ

FAQ Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit and check the machine to my factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Q: How about the after-service?

A: We will send 1 engineer to the buyer’s factory for a 10-day period installation and training to the operators.

Q:do you supply any formula to buyer?

A:yes, we supply formula to buyer,

Why so many customers choose us :

1. Advantage technology

2. High quality material

3. Tight quality control

4. Accurate machine

5. 7 - 24 hours service

1.Use anti-rust oil to wipe the equipment for flour tortilla chips making machine nacho making extruder

2.air cushion film packaging equipment for flour tortilla chips making machine nacho making extruder

3.with a wooden box for the final step of packaging.