Small scale Tortilla chips making machines

Description1. Description:

A tortilla chip (Doritos, nachos, corn chips) is a Small scale Tortilla chips making machines made from corn powder, which are cut into wedges and then fried (alternately they may be discs pressed out of corn masa then fried or baked). Corn tortillas are made of corn, vegetable oil, salt and water. Though usually made of yellow corn, they can also be made of white, blue, or red corn. After frying and flavoring, we get very crunchy triangle chips which are popular with children and adult.

a. Raw Materials: adopts corn flour, rice flour, vegetable oil, salt etc. as raw materials.

b. Products:This line can be used to produce tortilla chips, doriots, nachos etc by adjusting the moulds from extruder;

c. Capacity: 100-150kg/h, 200-240kg/h

d. Flow chart: Mixing system---Extrusion system---Shaping system---Frying system----Flavoring system---Packing system

e. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

f. Machines Materials: All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

g. Technical Parameters:

Model | Installed power | Real power | Output | Dimension |

AMC65 | 119kw | 75kw | 100-150kg/h | 22000x1200x2500mm |

AMC70 | 120kw | 82kw | 200-240kg/h | 24000x1200x2500mm |

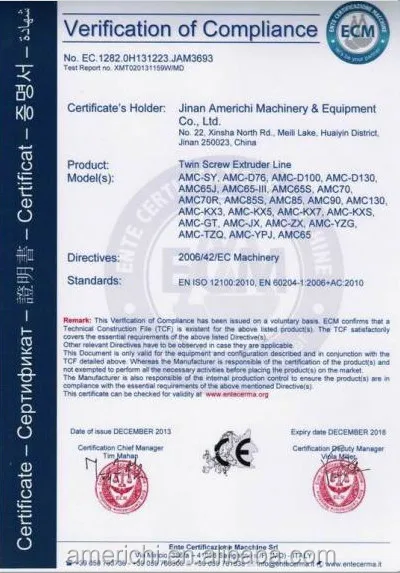

Certifications

This is our CE certification.

Production line

Small scale Tortilla chips making machines in our factory. Our technician can adjust it according to your factory size.

Multifunctional Continous Fryer. There are different heating source: Electricity, Gas, Diesel Oil, LPG etc for this machine. We match suitable one according to your requirement.

Twin screw extruder

A. Main Parts of Twin screw extruder with electricity heating system:

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

b. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. Small scale Tortilla chips making machines(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from Small scale Tortilla chips making machines(CHINA), ensure its powerful extrusion and excellent performance.

Twin screw extruder with Electricity Heating. We have different model Twin Screw Extruder with different capacity, May I know what Capacity you are looking for?

Sample Photos

We can get different shapes like: triangle, hexagon, square, round etc by changing different pressing roller. May I know what kind of shape do you prefer?

About US

Main Machinery

We are a professional food machines manufacturer in Jinan City, China. We have much experience in Extrusion Small scale Tortilla chips making machines processing, including Directly puffed Small scale Tortilla chips making machines machine, Shaping and core filled Small scale Tortilla chips making machines machine, Fried Crispy Small scale Tortilla chips making machines machine, Popular Breakfast cereal Corn Flakes machine, Baby food machine, TVP/TSP machine, Modified Starch machine, Dog food machine and Fish food machine etc.

Reputation

We have locked 70% share in the Small scale Tortilla chips making machines market all over the world and exported many countries, like USA, Mexico, Brazil, New Zealand, Uzbekistan, India, Saudi Arabia, Ethiopia, Uganda, South Africa, Germany etc.

Strength

Our exceptional engineering team can guarantee customers’ quality machine which can be up to design requirement and perfect working state. Our technician can also provide all kinds of relevant technology to make food healthy and safe.

Customer visiting our factory

Strong Fumigation-Free Cases For 20' GP & 40' HQ

Packed by standard wooden case outside and wrapped by plastic film inside then shipped by container.

Installation & commissioning in customer’s factory

Our Services

We provide Satisfied Service and Turnkey Solution for you

A. Pre-sale services

1). Provide the free consultation of the equipment;

2). Provide the standard device and the flow chart;

3). According to the clients’ special requirement, offering the reasonable plan and free

design helping to select the equipment;

4). Welcome to visit our factory or the domestic clients’ factory.

B. Services during the sales

1). Free management of equipments' long distance shipping;

2). Provide factory layout according to your factory size in advance;

3). Provide the basic formula;

4). Inspect the machine before leaving the factory;

5). Oversea installation and commissioning the equipment;

6). Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

7). Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

8). Provide English Version of Installation/Operation/Service/Maintenance Manual.

C. After sale services

1). Provide 1 year complete warrantee and life-time maintenance service;

2). Provide the spare parts will at preferential price for an extended long time;

3). New design in machines and formula suggestions;

4). Provide technical exchanging.

FAQ

A. Finished time

The production line will be finished in 30-40 days after confirmation.

B. Payment Term

30% is paid by T/T as the down payment, 70% is paid by T/T or T/C as balance before shipment.

C. Delivery Time

When the machines are finished, we will invite you to our factory for machine commissioning.