Doritos tortilla corn chips processing line making machine extruderNachos doritos corn chips machine Making Machine brief description:

Doritos tortilla corn chips processing line making machine extruderNachos doritos corn chips machine Making Machine brief description:Nachos doritos chips machine/Puffed Rice Ball Making Machine always use wheat flour ,corn flour as raw material through twin screw extruder extruding , then through forming machine to roll cut different shapes of products ,such as bugles,doritos, flat bread snacks, sala sticks, rice chips and also Fish shape,Moon shape, Bugle shape,Duck shape etc. Snacks.

Nachos doritos chips machine/Puffed Rice Ball Making Machine is foodstuff equipment researched and developed on the basis of international advanced technology. The performance and quality have reached the highest international level of the same line. From feeding materials, extruding and inflating, roasting, spraying to finished products are done once time with automation. We fill the gap of the first-class food produced with extruded and inflated technology.

Nachos doritos chips machine/Puffed Rice Ball Making Machine introduction :

This Nachos doritos chips machine/Puffed Rice Ball Making Machine can be used to produce different sizes of Flour Snacks, the shape can be changed by the Forming machine’s Roller Cutter. It could be Moon, Bugle, Round, Fish, Duck, Gourd etc.

1). The output is 120-150 KG/H, 220-250 KG/H

2). Extruder screws quantity is two.

3). The main body material is stainless steel, which is easy to be cleaned.

4). The screws material is 38CrMoAl, which is wear-resisting.

Products: All shapes of Doritos, shapes like round, triangle, hexagon etc. The size of products can be changed according to clients’ requirements.

Flow Chart: Mixing — Extrusion — Shaping — Separating — Baking — Flavoring

Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage of different countries.

Machines Materials: All the machines are made by food grade stainless steel.

| Mode | SLG65 | SLG70 |

| Capacity | 120-150KG/H | 220-250KG/H |

| Power | 70KW | 100KW |

| Dimension | 18000×2000×2500mm | 20000×2000×2500mm |

The Pictures of Tortilla chips making machine:

Why choose us :we Provide Satisfied Service & Turnkey Solution:

Why choose us :we Provide Satisfied Service & Turnkey Solution:a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

2).It consists of feeding system, extruding system, cutting system, heating system, driving system, lubricating system, water-cooling system and controlling system.

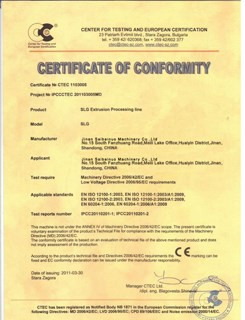

Certifications

Certifications

Our Service

Our Service

Pre-Sales Service:

1.Provide the free consultation of the equipment.

2.Provide the standard device and the flow chart.

3. According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

After-Sales Service:

1.Oversea install and debug the equipment.

2.Train the first-line operator.

3.Provide the basic formula.

| Packaging | |

| Size | 2500×1200×1800MM |

| Weight | 1.5 T |

| The normal package is wooden box(Size: 2500×1200×1800MM). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

| Packaging | |

| Size | 40FT high container |

| Weight | 6000kg |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |