extruded tortilla corn chips machinery

corn chips machine

crispy chips machine

doritos machine

1. Description

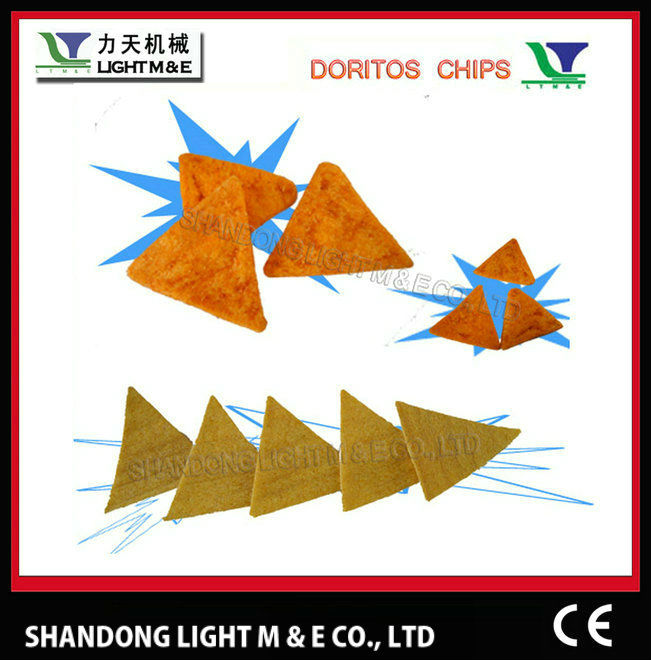

Doritos/totilla/triangle corn chips processing line. Doritos/totilla/triangle corn chips are kinds of snacks made from corn powder, which are cut and then fried. The main raw materials are corn powder, vegetable oil, salt and water. Although usually made of yellow corn(as pictured), they can also be made of white, or red corn. After frying and flavoring, we get very crunchy triangle or other shapes chips which are popular with both children and adult.

2. Raw materials: corn powder as usual

3. Products: all shapes of Doritos, shapes like round, triangle, Hexagon ect. The size of products can be change according to clients' requirements

4. Capacity: 200-250kg/h

5. Flow chart: Mixing ---Extrusion ----Shaping ----separating-frying ---Flavoring

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

7. Machines Materials: All the machines are made by stainless steel

8. Technical Parameters

Model | Installed power | Power consumption | Output | Size |

LT65 | 119kw | 75kw | 120-150kg/h | 22000x1200x2200mm |

LT70 | 126w | 82kw | 200-250kg/h | 24000x1500x2200mm |

9. Sample Pictures

10. Production

a.) Design: All the machines are elaborately designed by our mechanical engineers who are rich of experience in this field. We accept special design according to customer’s request.

b.) Processing & Assembling: Parts processing, assembly, testing are based on standard test.

c.) Trial Run: Each machine has to be tested before its deliver.

11. Delivery

The machines is possible to pack in wooden case or nude pack after wraping by plastic film.

12. Service & Installation

a.) Consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.