manufacturing snacks - nachos machine

Specifications : corn puffed snack extruder

1 Double Screw Extruder.

2 raw material: corn flour, wheat flour.

3capacity: 120-500kg/h.

4 manufacturing snacks - nachos machine

1. Description:

1.The main extruder adopts frequency speed controlling with high automation and stable per-formation.

2. manufacturing snacks - nachos machine are made of the alloy steel and special craft,durable usage,high pressure,the screw life is manufacturing snacks - nachos machine.Adopting the building block structure and combining willingly according to the different demand.

3.The forced lubrication system,so that it can guarantee the equipment transmission life is manufacturing snacks - nachos machine.

4.Auto-temperature control system, make the temperature controlling more direct viewing and the parameter more precise.

5.Self-cleaning ,when stopping ,it can be cleaned without desassembling.

6.According to different screw design rate to full different technology request.

7.This equipment has the wide material,multi-shape products and flexible collocations.We can produce the different products according to the different models (pellet, star , ring , moon , ball , stick or grain )and collocations.

2. Raw materials: corn flour, wheat flour ect.

3. Products: all kinds of snacks with different shapes and types .

4. Capacity: 120-150kg/h, 180-220kg/h,300-500kg/h.

5. Flow chart: Mixing ---Screw hoister ----Double-screw extruder ----Core filler ---Multi-function shaper---Hoister---Dyer---Flavoring machine.

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries.

7. Machines Materials: All the machines are made by SS202/304/316 stainless.

Food samples :

Our Services

Pre-sale services:

1> Provide the free consultation of the equipment

2> Provide the standard device and the flow chart

3> According to the clients’ special requirement, offering the reasonable plan and free design helping

to select the equipment.

4> Welcome to visit our factory or the domestic clients’ factory.

Services during the sales:

1> Help client design the factory and offering professional advice, free engineering drawing for the

factory layout.

2> Inspect the machine before leaving the factory.

3> Oversea install and debug the equipment.

4> Train the first-line operator.

5> Provide the basic formula

After sale services:

1> 24 hours online service

2> Engineers available to service machinery overseas

3> Provide technical exchanging

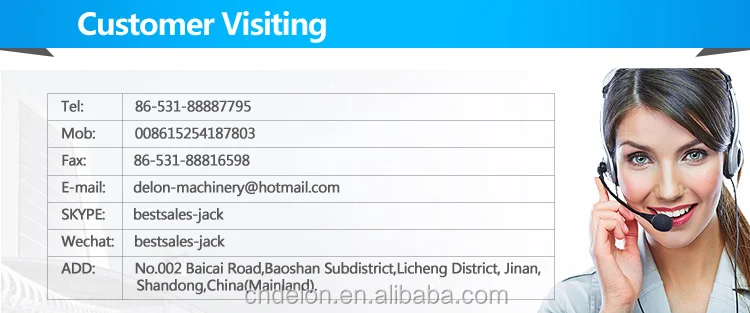

Company Information