Small Scale Corn snack production line

Specifications :

1 Double Screw Extruder.

2 Can take Raw material:

corn, rice, wheat, oat, barley, millet, sorghum etc as main ingredients.

Other material: salt sugar powder, flavor material, cocoa powder and so on….

3:Production Capacity: 120-500kg/h.

4 .Muti-fuctional:can products kinds of snacks,pet food.macaroni and so on.

kinds of snacks:puffed snack,core filling sanck,crispy snack,cereal porridge. and so on.

Puffed corn snacks extruder/ making machine/production line /processing line

Product Description:

1.The main extruder adopts frequency speed controlling with high automation and stable per-formation.

2.The screws are made of the alloy steel and special craft,durable usage,high pressure,the screw life is Small Scale Corn snack production line.Adopting the building block structure and combining willingly according to the different demand.

3.The forced lubrication system,so that it can guarantee the equipment transmission life is Small Scale Corn snack production line.

4.Auto-temperature control system, make the temperature controlling more direct viewing and the parameter more precise.

5.Self-cleaning ,when stopping ,it can be cleaned without desassembling.

6.According to different screw design rate to full different technology request.

7.This equipment has the wide material,multi-shape products and flexible collocations.We can produce the different products according to the different models (pellet, flower,star , ring , moon , ball , stick,ainimal or grain )and collocations.

"Low cost, high profits" is the suitable generalization of Small Scale Corn snack production line business line, especially for puff Small Scale Corn snack production line productioncan produce many kinds of snacks/puffedd snacks such as crispy rice flakes,core-filling snacks,cereal porridge,nutritional powder(instant porridge) etc.

.

Core filling/ Puffed Small Scale Corn snack production line machinery

Flow chart:

1.Mixer

2.Screw hoister

3.Double screw extruder

4.Core filler

5.Muti-function shaper

6.Hoister

7.Dryer

8.Flavoring machine

Parameter

Model | DL65 TWIN SCREW EXTRUDER LINE | DP70 TWIN SCREW EXTRUDER LINE | DP85 TWIN SCREW EXTRUDER LINE |

Installed capacity | 67kw | 104kw | 100kw |

Real power | 43kw | 82kw | 90kw |

Capacity | 120-150kg/h | 180-240kg/h | 350-500kg/h |

Dimension | 25000×1600×2400mm | 25000×1600×2400mm | 26000×1600×2400mm |

Voltage in China:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries.

Machinery Material

Good quality stainless steel

Packaging & Shipping

Wooden box

Our Services

Why choose us

1. Professional technology, we have been engaged in manufacturing food processing machine for many years, accumulating rich experience and enjoying high reputation.

2. Fast delivery and good service

3. All the machines are strictly inspected before making shipment.

5.Provied basic formula

Our Terms and After-sale Service

1.Delivery time:40 days after we receive the deposits

2.Payment: 30% deposits, balance against copy of bill of lading or LC at sight

3.Installation and commision: seller will send 1 technician to buyer's factory, All expenses including visa, round trip tickets, daily accommodation will be on the buyer’s account

4.Warranty is for one year

5.Accessory and spare pats will be offered with the whole line

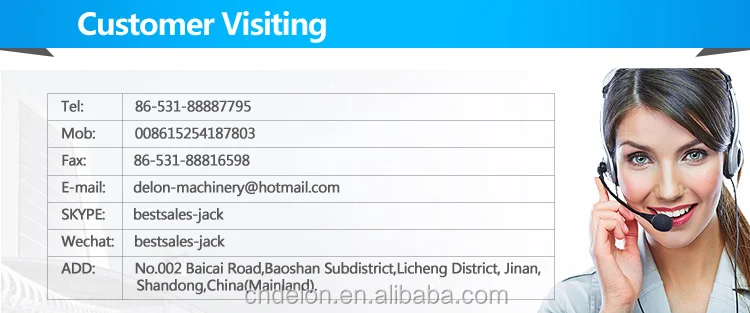

Company Information

Delon Machinery is a high and new technology enterprise integrating technology,

manufacture and trade. We have devoted ourselves to developing,

manufacturing and trading double/single screw extruders, snack production lines,

breakfast cereal/corn flake production lines, soya meat production lines,

pasta/macaroni production lines,pet food production lines, etc. for more than 10 years.

Welcome to our factory~

Company Information