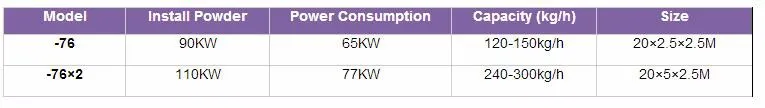

1. Technical Parameters of corn chips/cheese curls/cheetos/kurkure extruder machinery:

2.The brief description of corn chips/cheese curls/cheetos/kurkure extruder machinery:

1).Cheetos is a special extruded snack with extreme crispy taste.2).The main raw material is corn grits which is mixed with water evenly by the flour mixer, squeezed and twisted by the extruder to form the irregular curls shape, and then cut into different length, at last fried or baked and flavored.Such snacks with rich taste are always the customer's favor.

3.Raw materials: adopts corn grits as raw materials meanwhile mixing with water and oil

4. Products: This line can be used to produce fried or baked cheetos, kurkure, cheese curls, and nik naks with a continuous fryer.

5. Capacity: find attached below form.

6.The production process flow:

Mixer---Screw conveyor---extruder--Elevator---dryer---Automatic flavoring machine/Oil sprayer --cooling machine.

7. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

Jinan Saibainuo Machinery for food machine manufacturer in China since 2004, offer competitive advantage machines, so with us your money in safe, your business in safe.

About our twin screw extruder:

Detailed Images

Detailed Images

Name: high speed mixer

Dimension(m): 1.1×0.8×1.4

Motor Power: 4KW

Speed: 400rpm

Functions:

Mix the corn grains and water together with high speed.

Features:

1. stainless steel material

2.no material leak

3.High speed can mix material better.

Name: screw conveyor

Dimension(m): 3.2×0.6×0.7

Motor Power: 1.1KW

Screw speed: 300rpm

convey height range: 1.5~2.5M

barrel diameter: Φ160mm

Function:

Power and grains material can be conveyed in the stainless steel roller to the feeder of extruder without leaking, dust and pollution; feed quantity is even and stable.

Name: DLG 76 extruder

Dimension(m): 2.2×1.0×2.3

Total power: 23kw

Main Motor Power: 15KW

Cutting motor: 7.5kw

Extruder diameter: Φ76 mm

Function:

Extrude and cook raw material . Finally cut the product.

Features:

Screw material is 38CrMoAl with nitriding treatment, the hardness is 60HRC. The barrel also use good material, hardness is 55HRC.

All motors can be adjusted the speed by Inverter.

Name: dryer

Dimension(m): 5.4×1.3×1.8

Heating Power:27kw

Motor power:0.75kw

Belt speed:0.1-10M/minute

Temperature: 20-200℃

Function:

There are three layer inside,each layer is 5 meters long, it can save space and energy. Electricity heating,used to bake and dry food.

Features:

The net belt running speed can be controlled by Inverter, to change the food drying time in the dryer.

Heating adopts the electric heat tube.

It has automatic temperature Control system.

The belt and the cover are all stainless steel

Name: flavoring line

Dimension(m): 2.6×0.85×1.85

Motor Power: 1.5KW

Function:

Scatter the seasoning powder on the surface of food, Make food nice taste.

Feature:

Stainless steel material

Name: cooling conveyor

Dimension(m): 5.0×0.7×1.1

Motor Power: 1 KW

Function:

Cool the food after flavoring ,make the food suitable for packing.

Feature:

Stainless steel material

Have fans and baffle,better cooling and no leakage

Certifications

Certifications

Our Service

Our Service Packing & Delivery

Packing & Delivery

Related Products

Related Products

corn flakes making machine

99.8% Response Rate

pasta making machine

99.6% Response Rate

TSP making machine

98.9% Response Rate