Extruded Tortilla Corn Chips Machinery

Product Description

Description of Extruded Tortilla Corn Chips Machinery

China Manufacture OF food Machinery Extruded Tortilla Corn Chips Machinery Tortilla Corn chips are kinds of snacks made from corn powder, which are cut and then fried. The main raw materials are corn powder, vegetable oil, salt and water. Although usually made of yellow corn(as pictured), they also can be made of white or red corn. After frying and flavoring, we get very crunchy triangle or other shapes chips, which are popular with both children and adult.

1. Raw Materials: Corn Powder as Usual

2. Products: All shapes of Doritos, shapes like round, triangle, hexagon etc. The size of products can be changed according to clients’ requirements.

3. Capacity: 150Kg/h ,250Kg/h

4. Flow Chart: Mixing—Extrusion —Shaping —Separating—Frying/Baking —Flavoring

5. Voltage: Three phases: 380V /415V /440V /220V, we can make it according to customers' Local voltage according to different countries

6. Machines Materials: All the machines are made by food grade stainless steel

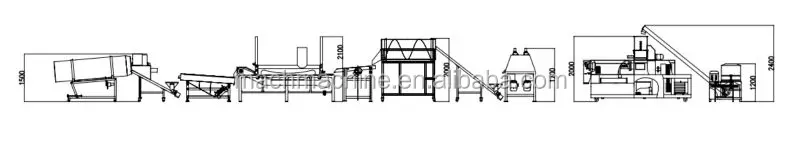

Flow Chart of Extruded Tortilla Corn Chips Machinery

Technical Parameters of Extruded Tortilla Corn Chips Machinery

Model | Installed Power | Power Consumption | Output | Dimension |

MHSJ6 Process Line | 119Kw | 79Kw | 100-150kg/h | 22000*1600*2400mm |

MHSJ7 Process Line | 129Kw | 88Kw | 200-250kg/h | 24000*1700*2500mm |

Packaging & Shipping

Fumigation Free Ploywood or 20'GP 40'HQ

Our Services

Service And Turnkey Solution

A .Consultation service before, during, and after sales.

B. Project planning and design service.

C. Debugging of equipment until everything is functional .

D. Management of equipments' long distance shipping from seller's factory to the Destination Port .

E.Training and Guiding Buyer about equipment maintenance and operating personally.

F. New production techniques and formulas for basic Shaping.

G. Provide 1 year complete warranty and life-time maintenance service.

H. Provide Long-time Technic Service and After Service

Contact Information