Corn Flakes Production Line

Warmly welcomed all customers around the world !!!

Contact details :

Vivian

skype : lrfoodextruder

Product Description

Corn flakes machine features: es Plants

1.Corn flakes machine is one kind of crispy foods, adopting corn powder as basic materials

2. Fast and nourishing food with given structure, such as granule shape, flake shape and animal shape

3.Its outstanding characteristic is containing abundant compound carbohydrate and meal fiber

4.corn flakes can be added with cocoa and sugar, such as honey and maltose

5.You can enjoy it directly by mixing with coffee, milk, yogurt or functional drink

6.Children can have breakfast of sweet crispy snack

7.This processing line can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruels, nutrient-flour, and baby food and so on.

8.The screws are made by ally steel and special craft, the screw life is Corn Flakes Production Line, uses building block system structure, may combine willfully.

9.The forced lubrication system, by guaranteed equipment transmission Corn Flakes Production Line life.

10.Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

Capacity: 150kg/h, 240kg/h,350kg/h

Equipment of corn flakes/breakfast cereals production line:

Mixer--- Screw conveyor--- Extruder--- Air conveyor--- Flaking(tabletting) machine--- Air conveyor--- Pre-dryer--- Hoister--- Vibrate sifter-- Baking machine-- Air conveyor---Sugar sprayer---Multi-layer oven---cooling machine

Technical Parameter:

| LRS65Corn flakes processing line | LRS85 Corn flakes processing line |

Installed capacity | 166KVA | 263KVA |

Power | 110Kw | 200kw |

Output capacity | 120-150kg/hr | 240-300kg/hr |

Dimension | 45*3.0*4.0m | 48.5*5.0*4.0m |

Corn fakes samples:

Electric component brand :

Extruder Details

Twin screw extruder adopts the extrusion technology.

After the cereals is extruded, the products will become bigger, puffy texture, crisp taste, starch form, increasing the water dissolve, easy to absorb by human, thus, it is popular in the world.

Twin screw extruder has the following part:

feeding system, extrusion system, cutting system, heating system, lubricating system, driving system, control system

Packaging & Shipping

Packaging & Shipping

1.Testing Machine before package

2. Packaging: inside is covered in plastic film, outside is wooden case

3. Shipping: 15-35 working days after receiving deposit

1.Manufacture:

1)Keep the quality the first.

2)Make more products benifit to customers' need.

________________________________________________________________________

2.Online/Sale service:

1) solid quality.

2)Fast and punctal delivery

3)Standard export package or as customers' need.

________________________________________________________________________

3.After-sale service:

1)Assistance to build factory or your project.

2)Repairing and maintenance if any problem occur in the warranty.

3)Installation and clerks training.

4)Spare and wearing parts for free or with big discount.

5)Any feed back of machines can be told us, and we will try our best to support you.

________________________________________________________________________

4.Other cooperate service:

1)Technology knowledge share.

2)Factory building advising.

3)Business expansion advisin

FAQ

A. What's the pre-sale service of your company?

Related machines’s technical parameter will be supplied to customer.

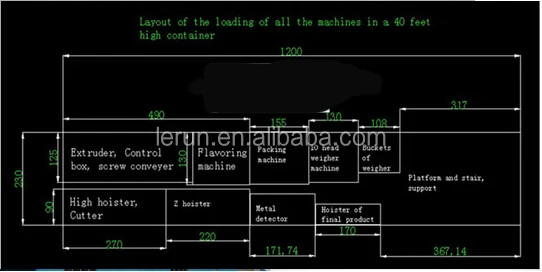

1. According to customer’s factory size, factory layout can be provided in advance.

2. According to customer’s material cost, general formulation can be prepared well.

3. Special machine can be supplied as customer’s request.

4. Professional Advice about Market, machines, processing , materials, packing can be supplied.

5. Suggesting professional ship agent or helping book ship as customer request.

B. What's the after-sale service of your company?

1. Allocation chart as the buyer’s request will be supplied.

2. Operation manual will be supplied after shipment.

3. One year warrantee, life time maintenance with cost price.

4. Free easy broken spare parts will be sent with container .

5. First installation can be done by engineer.

6. Training workers in customer’s factory.

C. If machines wearing parts need changing, what should we do?

We can offer the wearing parts all the time, and offer video.

D. What's the payment terms if we want to buy the machines?

L/C, T/T 30% down payment, 70% balance before delivery.