CE Certified Core Filling Low price rice puffing corn snack production line Processing Line/Machine/Machinery/Plant/Production Line

Introduction

DARIN'S Puff Low price rice puffing corn snack production line Processing Line can produce all kinds of extrusion foods, such as snacks, breakfast cereal, core filling bars with honey, chocolate or cream in center, etc.

Why Choose Us?

1. Germany WEG motor, three years worldwide guarantee

2. Low price rice puffing corn snack production line PLC and touch screen to control the whole line, all faults will display on the touch screen

3. ABB or Schneider electric parts

4. NSK bearings

5. All parts touch with raw materials or final products are made of stainless steel 304

6. 24V operation voltage, assure the safety of operators

7. Three kinds of protectors to keep machine and operator safe: over-heating, over-current, over voltage.

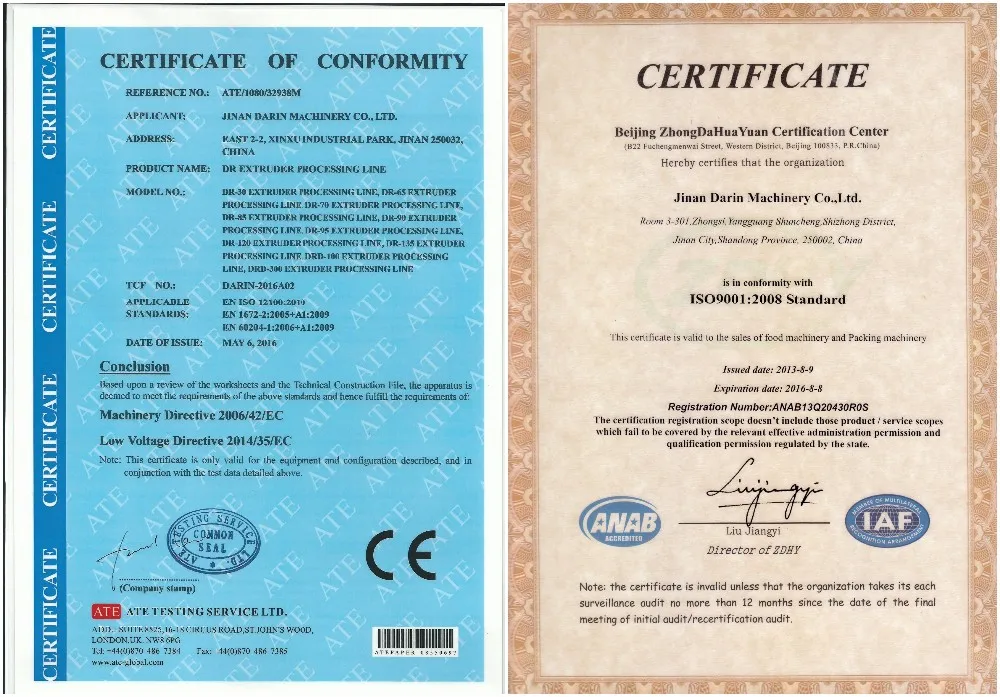

Certificate

Samples Picture

Mold

Advantages

Stainless steel structure, especially the parts in contacting with the raw material or products;

A wide range of products can be obtained in a variety of different ways, and can configure various dies simply and rapidly.

The use of a continuous automatic process provides greater production outputs than offered by traditional systems, with savings in energy and reduced management cost;

Automatic dosing unit for utilization with any type of flours and starches (the size should be 60-80mesh);

The screws are all made by 38CrMoAIA and alloy layer with the hardness of 55HRC, which is hard and strong, and has Low price rice puffing corn snack production line service life (1.5-2 years);

Barrel is divided into 3 parts; the hardness of the barrel is 55HRC;

The barrel and the screws are modular in structure. Each module is equipped with its own thermoregulation ring with cooling circuits and electric heating resistances;

Technical Parameters

| Model | DR-65 | DR-70 |

| Capacity | 120-150kg/hr | 150-200kg/hr |

| Power | 92kw | 140kw |

| Dimension | 23 x 5 x 3m | 25 x 5 x 3m |

Key Equipment Show

Commissioning & After-sales Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After delivering machines to client’s factory, we start to apply for the Visa to client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5. It normally costs 10 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

6. The engineer’s round-trip flight tickets, accommodation and daily saLow price rice puffing corn snack production line USD 60 are on client’s account.

Darin's Factory

Delivery

Exhibiton

Contact Information