Jinan Eagle Food Machinery Co., Ltd located in Qijia Industrial Zone, Daqiao Road, Licheng district, Jinan city, capital of Shandong province.

We are professional manufacture of food extrusion production systems. The production process from technical drawing, welding, drilling, Lathe turning, measuring, testing in real production, whole procedures controls all equipments quality.

From ingredients preparation, mixing, extrusion cooking, additional cutting machines, dryers, fryers, flavor coating machines, packing machines, forms the different continuous production plants.

Jinan Eagle Food Machinery company machines have distributed the machines to many different countries, Vietnam, Indonesia, Malaysia, Thailand, Lithuania, Italy, United states, Cheli, Peru , South Africa, Kenya, Libya etc.

Equipment we supply

Twin screw extruder, Single screw extruder, Rotary disk corn twisties extruder machine,Dryer/oven, fryer, flavoring machine, Packing machine, Mixers, Flavor spraying machine, tumblers, Screw conveyor, belt conveyors

Product Description

Breakfast cereals machine

Introduction of machines

(1)General Introduction

This production line is developed and manufactured on the basis of the international advanced extruder

technology, which is named corn flakes (breakfast cereals) production line. Its technology performance

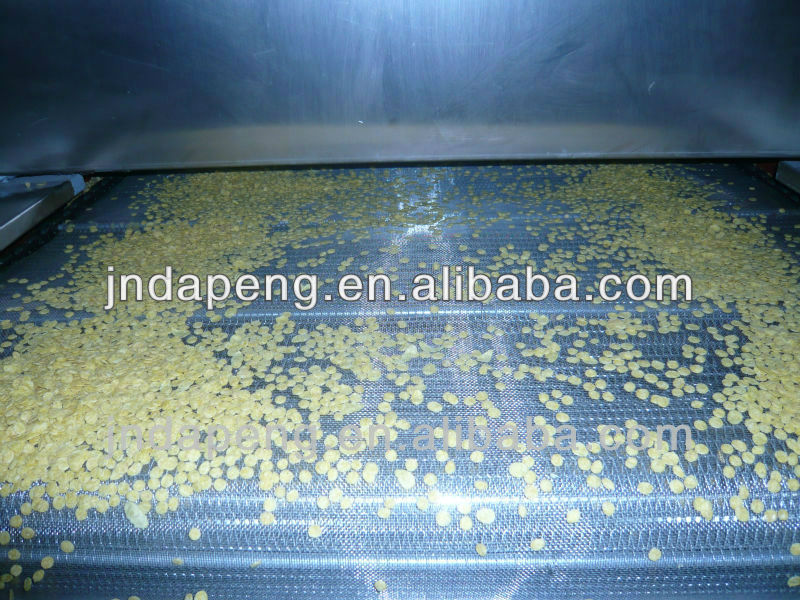

and quality can be reached international advanced level,consisting of mixing, extruding, inflating, flaking,

and drying. The whole production is done at one stream under full automatically working.

Corn powder is the major material in the production line. Extruding & shaping workmanship enables the

appearance of the products to look better and natural and taste delicious and crisp, without cracking. The

line is characterized by proper design, stable

performance, and high automation. Main engine adopts advanced frequency & speed controlling technology,

so it can save energy and be efficient. Accurate parameter and fine workmanship flow ensure stable quality

of the products, which are integration of traditional arts and modern technology.

(2)Shapes

For breakfast cereals in different shapes and textures, e.g. puffed rice, corn flake type shapes, rice crispies, honey bears and many more

(3)Extrusion raw materials:

Maize, wheat, rice, salt, sugar, malt, milk powder, glucose, honey and many more

(4)Flow char

Breakfast cereals such as the ring shape, honey ball shape, rose shape, star shape,

are expanded during extrusion die-cutting. Corn flakes is expanded/bubbling during high temperature toaster,

Corn flakes flow chart

Mixer---extruder---vibrate cooler---rollers drying machine---flaking---air conveyor--- roasting---high temperature inflate---second vibrate cooler---sugar coating machine---multi-layer oven---cooling--packing

Our Services

Q1: If we buy machines, what is the after-sale service?

Jinan Eagle Food machinery manufacture will send the engineer to buyer’s factory. Offer the trainee program, start the related food production as customer request.

Q2: If machines wearable parts need to change, what should we do?

Jinan Eagle Food machinery manufacture will offer the wearable parts all the time. And offer the on-line video instruction for the operation.

Q3: What is the payment terms if we want to buy the machines?

Usually it is 30% by T/T, pay the balance by T/T before delivery or L/C at sight

Packaging & Shipping

Package: Wooden case, plywood case, fumigated wooden case for package.

Shipping: By sea in 20 feet, 40feet containers