Extruded crispy corn puff Extruded crispy corn puff snack food machine machine

Brief Introduction

This corn puff snacks production line is appled to make directly puffed / extruded snacks with different shapes , the main raw material is corn flour ,wheat flour, rice flour and so on . With core filling machines and the shapers , you can also make core-filling snacks with this proruction line .]

A typical co-extrusion processing line includes mixing and oil spraying systems, a twin-screw extruder at the heart of the process and shaping equipment. Drying, coating and cooling devices are then used accordingly.

Extruded flakes can also be made on the same lines with complementary equipment.

Ingredient flexibility to process a wide variety of :

- Outer parts with various materials : wheat, rice, corn, whole grain etc.

- Fillings : chocolate flavors, jellies, fruit pastes, honey, yoghurt, etc.

- Shapes : pillows, tubes, bars, triangles, nuts, balls, long and short ovals and specialty profiles, etc.

- Expertly crafted co-extrusion dies with optimized flow design

Production Flow

I. This corn puff snacks / core filiing snacks production line is composed of the following machines :

- Flour mixer

- Spiral elevator

- DG75-IIextruder

- Core filling machine

- Double-rollers shaper

- Large elevator

- 5-layers fuel oven

- Large elevator

- Oil spraying flavoring line

Model | Installed power

| Power consumption | Throughput | Dimension | Product |

DG65-III Twin screw extruder |

50kw |

38kw |

100~150kg/h |

25500×3000×3000mm

|

Core filling snack Puffed snack |

DG75-III Twin screw extruder |

82.3kw

|

62kw

|

200~300kg/h

|

27400×3200×3100mm |

Double core filling snack

Puffed snack |

DG85-III Twin screw extruder |

121.8kw

|

91kw

|

350~500kg/h

|

27900×3000×3500mm

|

Double core filling snack

Puffed snack |

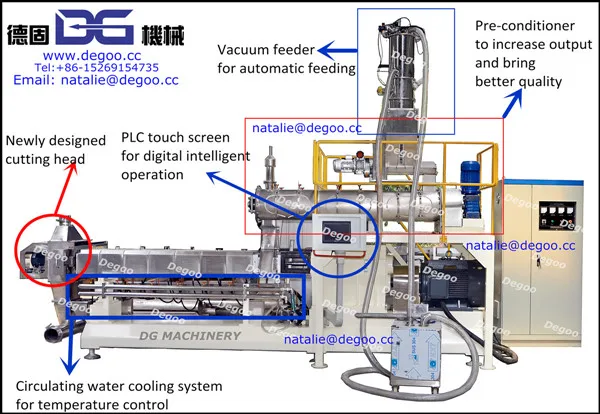

DG Extruder

DG75 NEW SERIES SWISS TECHNOLOGY TWIN SCREW EXTRUDER

Twin screw / single screw extruder for snacks ,soya, breakfast cereal corn flakes ,cheetos, snack pellets ,pet food ,fish feed and so on

1. Swiss technology , made in China

2. PLC touch screen for accurate and convenient control

3. Direct transmission of motor and distribution box reduces energy loss.

4. Imported bearing with high carring capacity.

5. Applied to various materials with totally enclosed type compulsive feeding way.

6. With water injecting device on barrel, it can adapt to the requirements of materials and quality.

7. The screw is made of high-speed tool steel with hardness > HRC62 ,which has a Extruded crispy corn puff snack food machine servive life.

8.Cordwood combined screw is applied to different materials and products with certain screw combination.

9.Independent and precise temprature control in each section ,automatic water cooling system

10. Suspension type rotary cutter with liner bearing adjusting device to ensure quick ,safe and accurate cutter adjusting.

Company information

Extruded crispy corn puff snack food machine Machinery Co., LTD. is Extruded crispy corn puff snack food machine manufacturer of Extruded crispy corn puff snack food machine extrusion machinery . We are the only company that combines European technology with Chinese equipment. since inception to the present, DG's goal is to provide customers with optimized extrusion solutions. “The best quality and super service” is our constant spirit. DG offers the most practical and advantageous solutions for the production of various breakfast cereals and snacks, as well as for the production of animal feed, vegetarian protein and artificial rice.

Our products are widely exported to many countries such as: Russia, Australia, USA, Canada, Argentina, Uzbekistan, Tajikistan, Belarus, Mexico, etc.

We accept OEM orders, also can according to your needs to produce equipments. We have professional team to set up the equipments and also offer the technology and recipes.

Our Services

I. DG has professional team to design the whole production line according to your requirements

II. we also help our client to develop the old production line and carry out new products

III. Custiomized factory layout designed is provided by our professionals

IV. Overseas technicians are available to help the clients for installation and adjustment

V. 12 months warranty for the machines , 24 months for some parts

Packaging & Shipping

I. To ensure long distance transportation ,DG uses best quality wooden case for the machines , besides , for the over-size machines ,we will fasten them reinforce them with steel frame.

II. The machines will be ready for disparch around 20~60 working days according to your requirements , some of the machines are available in stock , which can be made delivery once you placed the order .

FAQ

More detailed information and the best price will be offered ,pls feel free to contact :

Prodution lines

1. Soya protein production line

2.Snack pellets production line

3.Corn puff snacks production line

4. Pet food / fish feed production line

5. Breakfast cereal corn flakes production line

6. Cheetos / Kurkure snack production line

7. Artificial rice production line