Commercial kelloggs corn flakes and breakfast cereal production machine

Brief introduction of the corn flakes and nutritional cereal processing line:

..................................................................................................................................................................

Corn flakes is a kind of crisp food, used grain flour as the basic raw material. By the processing line it is processed to

flakes instant food which is pressed by particle. The outstanding feature is that it is rich in composite carbon compounds

and dietary fiber. At the same time, corn flakes can not only strengthen much trace element, such as vitamins and minerals,

but also add cocoa and sugar,such as honey,maltose, etc. After adding into coffee,milk,yogurt,or functional drinks, we

can directly eat it. Children can also eat it as sweet and brittle leisure Export full-automatic cheerios weetabix Corn flakes breakfast cereals processing line machine.

1. Raw Materials: Main corn Powder and Other Cereals Powder

2. Products: All kinds of snacks with different shapes and types.

3. Capacity: 60-80 KG/H,100-150KG/H ,200 -250KG/H,300-350 KG/H

4. Flow Chart: Mixing —Extruding —Flaking —Drying — Baking —Coating —Baking —Cooling

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ,

also can make it according to customers' local voltage of different countries

6. Machines Materials: All the machines are made by food grade stainless steel.

Technical Parameters of Breakfast Cereal Production Line :

| Model | Installed power | Power consumption | Throughput | Dimension |

| DG32-II processing line | 135KW | 101KW | 60-80kg/h | 45X2.8X2.7M |

| DG52-II processing line | 210kw | 168KW | 100-150kg/h | 54.7X2.8X2.7M |

| DG75-II processing line | 292KW | 219KW | 200-250kg/h | 64.2X3.2X3.1M |

| DG75-II B processing line | 342KW | 256KW | 300-350kg/h | 69X3.3X3.8M |

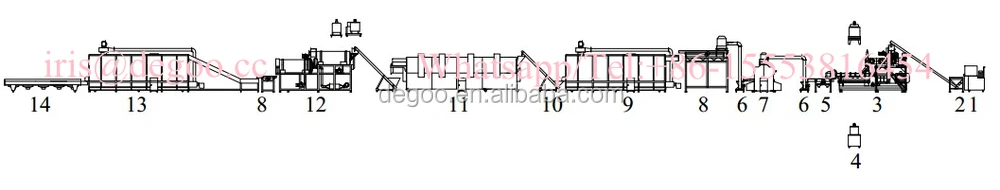

CAD drawing of Corn Flakes and Breakfast cereal production line (Example:300-350kg/h):

Brief introductions of single machines of the corn flakes and cereal processing line:

1.Flour mixer : to mix various raw materil evenly.

2.Screw conveyor : to convey raw material to extrude

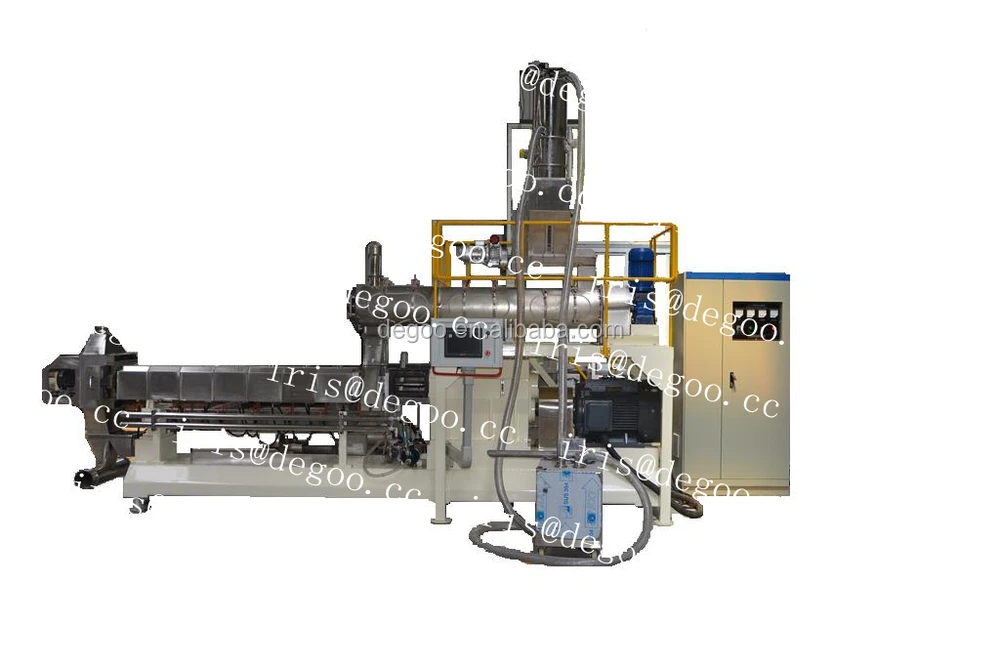

3.Twin/Double screw extruder :to extruder and cook the raw material into different shapes breakfast cereal

4.Water injector: to inject water on the producing process.

5.Vibrating cooler: to spread the products and cool it quickly.

6.Air conveyor: to convey the food to the next machine

7.Flakes presser: to press the particles into thin flakes (its size of flakes can be adjusted)

8.Higher vibrating cooler: to spread the flakes and sancks food and cool it quickly.

9.Belt drying oven: to dry snacks food by circulating belt.

10.Belt conveyor: to elevate the snacks food to the next machine

11.High temperature toaster: to use hot air to dry the snacks food.

12.Flavoring machine: to spray flour ,sugar oil and other seansons on the food to get decilious food.

13.Extending drying oven: to dry the corn flakes after it being coated sugar.

14.Cooling conveyor: to cool food.

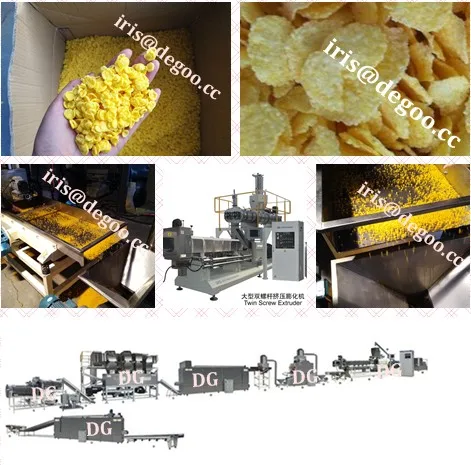

Breakfast cereal and corn flakes samples :

News designs machinery of corn flakes and cereal breakfast cereal :

Twin screw extruder with Pre-conditioners:

Higher capacity flakes presser:(250-300kg/h)

High temperature drying roaster:

Our Service & Turnkey Solution

a.) Consultation service before, during,and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

We are realiable corn flakes machienries manufacturer with CE ISO CIQ certificate:

Corn flakes and breakfast cereal machinery manufacturing and demonstrating workshop:

Welcome to visit our factory to check and test our machines:

Packaging and shipping:

About us :Export full-automatic cheerios weetabix Corn flakes breakfast cereals processing line machine machinery co.,ltd in China:

We: Export full-automatic cheerios weetabix Corn flakes breakfast cereals processing line machine machinery co.,ltd located in Jinan ,Shandong Province ,China, is the professional manufacturer of

Export full-automatic cheerios weetabix Corn flakes breakfast cereals processing line machine processing machinery.We specialize in this field for may years ,not only can supply with the entire machiner

design,but also can modify the production line to meet client's demand.All kinds of patents , proprietary technology ,

breakthrough and certificated .

There is a testing center in our factory which combined experiments,dmonstration andtrainingin one facility.We also

can test new technical experiments according to customer requirements .

Our extrusion systems are widely used in:puffed Export full-automatic cheerios weetabix Corn flakes breakfast cereals processing line machine,breakfast cereals,corn flakes ,nutritional artificaila rice,

textured or fibre protein food,pet food,aquatic feed,modified starch,bread crumbs and other Export full-automatic cheerios weetabix Corn flakes breakfast cereals processing line machine.

If you are interested in us,pls no hestitate to contact us: