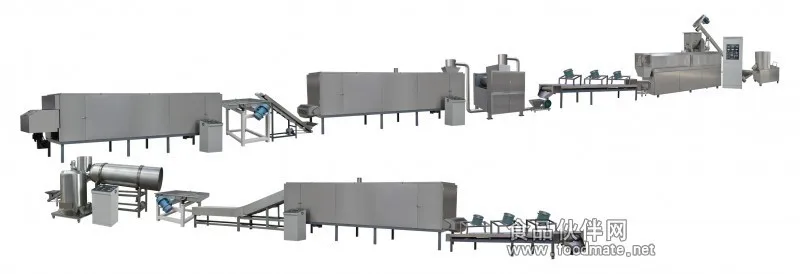

Automatic corn flakes/coco pops making machine

1. Introduction of The Production Machine

Automatic corn flakes/coco pops making machine is the most popular breakfast cereals in the world. It is a perfect cereal because of the crispy taste. Our corn flakes production lines are based on extrusion technology which is so widely used in food industry. adopts corn, rice, wheat, oat, barley etc as ingredients to make puffs snack. Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

2. Raw Material

Corn Grits (Powder), wheat flour, rice flour, oat meal, other grain meals

3. Different Models Production Lines for your choice

| NO | 1 | 2 | 3 |

| Extruder Model | MT65 | MT70 | MT85 |

| Capacity | 100-150kg/h | 200-230kg/h | 300-400kg/h |

| Dryer/Fryer Fuel | Electric/Gas/Diesel/LPG | Electric/Gas/Diesel/LPG | Electric/Gas/Diesel/LPG |

| AreaRequirement | 40000*5000*3000mm | 42000*5000*3000mm | 50000*5000*3000mm |

4.Different Products Production Lines for your choice

5. Flow Chart

Our company has rice experiences in this fiel. We are able to supply turnkey project including grinding system for raw material, production machines for cereal, packing system for final products, even other lab testing equipments, etc.

Flour mixing - Extrusion - Flaking - Drying - Roasting|Baking - Sugar Coating - Drying - Packing

6.Packing and Shipment

1. Packing: The product will be packed into wooden case or plastic , it depend on customer requirement,then into containers.

2. Transportation: According to what the buyer's requirement, we provide transport agent, buyer pay the transfer fee.

7.Production period

The machine will be delivered from factory during 20 working days after receive the buyer's advance payment.

8.Quality guarantee

The quality of equipment will be guaranteed for one year based on correct operation of buyer.

9.Testing & training

The plant layout design, assembling and installation, start-up and local team training will be free at no cost. But the buyer should be responsible for the round-air tickets, local transportation, accommodation, and US$60/day per person for the pocket money to our technicians.

10.Customer with us

11.Personal Information