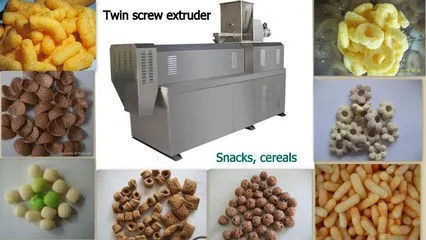

Product Application

Corn puff snack making machine adopt corn, rice, wheat, oat, barley etc as ingredients to make puffed snack. Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

2. Corn puff snack making machine Raw materials:

Corn, rice, millets, wheat, oat, barley etc as ingredients. Please note that all the materials should be in powder(flour) or grits form.

3. Corn puff snack making machine products shapes:

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

4.Corn puff snack making machineCapacity:

60-80kg/h 100-150kg/h, 200-240kg/h, 500kg/h 800kg/h

5. Corn puff snack making machine Flow chart:

Grain grinder---Mixing system---Twin screw Extrusion system----Drying system----Flavoring system--Packing system

6. China standard industrial Voltage for Corn puff snack making machine:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, We can make it according to customers' Local voltage according to different countries (400v 415v 480v...).

Main Features

5.factory price corn puff snack extruder food machine Feature:

1. Productive: Automated systems for controlled and consistent production on a continuous basis, easy and quick product changeover, automated start up, simple cleaning and maintenance procedures.

2. Flexible Formula: Processing of a wide range of raw materials, such as corn, wheat, rice, potato, oat etc;

3. Widly Appication: Easy adaptation to extend the range of products by changing the segments screw;

4. Smart Control System: PLC Control of production to ensure optimized process parameters for each recipe;

5. Advanced Die and Cutting system: This designs give processors an entirely new set of templates to create innovative shapes and sizes-Balls, animals, stars, rings, pillows, triangles, curls, chips, sticks, and also letters;

Detailed Images

Detailed Images

Machine Parts

Name: mixer

Brand: MT

Original: CHINA

IT mixing different type raw material together with water and oil,make it fully mix.

Main Features

Name:Screw Conveyor

Brand:MT

Power:1.1KW

The mixed materials can be conveyed in the

stainless steel roller to the feeding machine

(feeder) of extruder without any leaking ,

dusting and pollution; Feed quantity and

speed is even and stable.

Machine Parts

Extruder

Name:Double screw extruder

Brand:MT

Power:35KW

Output:100-150KG/H

By means of designing different structures and slenderness ratios according to needs of products,screw extruding system can meet different technology demands.

Main Features

Name:Electrical dryer

Brand:MT

Power:60KW

Output:100-260KG/H

It is used for drying .The net belt running speed can be controlled to change the food drying time in the dryer.Multi-layer dryer is with compact size

than other type dryers.

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

| Packaging | |

| Size | according to exact products |

| Weight | according to exact products |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Size | according to exact products |

| Weight | according to exact products |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate