Famous brand crispy breakfast cereal snacks maker machine

Brief introduction

I. Refer to the breakfast cereal corn flakes production line

The processing line is a fullly automatic line which combines DG professional team with the European advanced technology; It is a breakthrough to solve the problems regarding to sticky material on the roller,low output of flakes pressing ,low shaping rate ,poor taste and so on .Resonable equipments collocation and realizable process control ensure high quality and delicious corn flakes production.The processing line not only reduces costs by improving efficiency, but also improves market competitiveness.

II.Ready-to-eat breakfast cereals: flexible twin-screw extrusion technology

• Directly expanded cereals, flakes, co-extruded products combinations

• Integration of various raw materials: white or yellow corn, wheat, rice, cassava powder

• New features, shapes, textures, colors, coatings and fillings

• Nutritional products enriched in fibers, vitamins and multiple cereals.

III. The corn flakes production line is applied to make corn flakes, breakfast cereal snacks ,normal corn puff snacks with various shapes and flavors,

Production Flow

I. This corn flakes production line is composed of the following machines :

- Flour mixer

- Spiral elevator

- DG75-II extruder

- Cooling vibration

- Air conveyor

- Flakes presser

- Air conveyor

- Spreading and cooling machine

- 3-layers cooling machine

- Large elevator

- 5-layers fuel oven

- Large elevator

- High temperature dryer(4)

- Large elevator

- Double-drum spraying line

- Spreading vibrator

- 5-layers fuel oven(extended)

- 5-meters cooling conveyor

II. Technical parameter

Model |

Installed power |

Power consumption |

Throughput |

Dimension |

Product |

DG52-II Twin screw extruder |

210kw |

168kw |

100~150kg/h |

54700×2800×2700mm | Corn flakes Cereal grain |

DG75-II Twin screw extruder |

292kw |

219kw

|

200~250kg/h |

64200×3200×3100mm |

Corn flakes Cereal grain |

DG65-II Twin screw extruder |

89kw

|

67kw |

100~150kg/h |

37800×3000×3000mm |

cereal grains |

DG75-III Twin screw extruder |

109kw |

82kw |

200~300kg/h |

38500×3000×3000mm |

cereal grains |

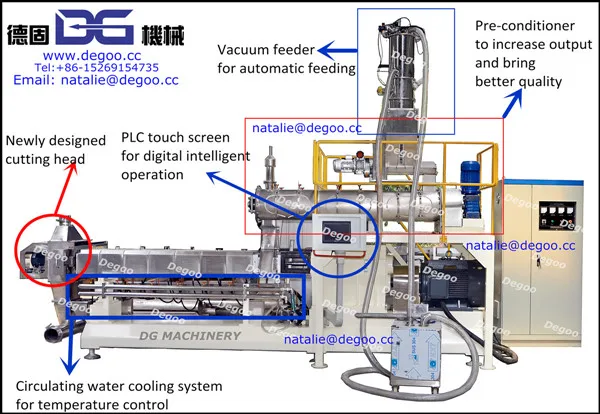

DG Extruder

1. Swiss technology , made in China

2. PLC touch screen for accurate and convenient control

3. Direct transmission of motor and distribution box reduces energy loss.

4. Imported bearing with high carring capacity.

5. Applied to various materials with totally enclosed type compulsive feeding way.

6. With water injecting device on barrel, it can adapt to the requirements of materials and quality.

7. The screw is made of high-speed tool steel with hardness > HRC62 ,which has a Famous brand crispy breakfast cereal snacks maker machine servive life.

8.Cordwood combined screw is applied to different materials and products with certain screw combination.

9.Independent and precise temprature control in each section ,automatic water cooling system

10. Suspension type rotary cutter with liner bearing adjusting device to ensure quick ,safe and accurate cutter adjusting.

Company information

Famous brand crispy breakfast cereal snacks maker machine Machinery Co., LTD. is Famous brand crispy breakfast cereal snacks maker machine manufacturer of Famous brand crispy breakfast cereal snacks maker machine extrusion machinery . We are the only company that combines European technology with Chinese equipment. since inception to the present, DG's goal is to provide customers with optimized extrusion solutions. “The best quality and super service” is our constant spirit. DG offers the most practical and advantageous solutions for the production of various breakfast cereals and snacks, as well as for the production of animal feed, vegetarian protein and artificial rice.

Our products are widely exported to many countries such as: Russia, Australia, USA, Canada, Argentina, Uzbekistan, Tajikistan, Belarus, Mexico, etc.

We accept OEM orders, also can according to your needs to produce equipments. We have professional team to set up the equipments and also offer the technology and recipes.

Our Services

I. DG has professional team to design the whole production line according to your requirements

II. we also help our client to develop the old production line and carry out new products

III. Custiomized factory layout designed is provided by our professionals

IV. Overseas technicians are available to help the clients for installation and adjustment

V. 12 months warranty for the machines , 24 months for some parts

FAQ