2D 3D snack papad pellets manufacturing machine

Snack pellets lineI . What are the snack pellets ?

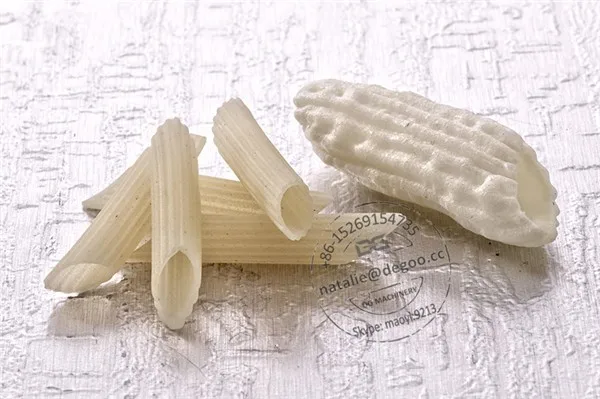

Snack pellets are intermediate non-expanded products made with raw materials that include cereals, potatoes or vegetable powders. These semi-finished products are generally sold to snack manufacturers who then process them, using different methods (frying, hot air baking, etc.) and adding various taste ingredients to create ready-to-eat snacks.

The market for snack pellets is growing fast because of their long shelf life and their high-density features, simplifying storage and making them convenient and economical to transport.

II. What is the difference between an expanded snack and a snack pellet?

Pellets become ready-to-eat snacks once they have been expanded.

Snack pellets can be made with a wide variety of grains – corn, wheat, rice, tapioca – or potatoes and other vegetables. They can also incorporate aromas and colors in their recipes.

III .Advantages:

- Ingredient flexibility – processing of a wide range of raw materials and easy changeover

- Production of various shapes and sizes, using 2D and 3D matrices

- Multiple flavors and colors

- PLC control of production to ensure optimized process parameters for each recipe

I. The 2D/3D snack pellets production line is composed of the following machines( start from the rihgt side of the line) :

1. Mixer : to mix the raw material together equally

2. Conveyor : take the raw material to the extruder

3. Extruder : cook and extrude the material with high temp and pressure

4. Shaper and cutter : cut the snack pellets into different shapes

5. Elevator : take the snack pellets to the next machine

6. Oven : Dry the snack pellets with circulating conveyor for more than 2 hours

7. Frying system : fry the snack pellets to make them expand and crispy

8. De-oiling system : take away the oil

9. Flavoring line : make different flavors with flavoring seasoning

II. Technical parameter

Model |

Installed power |

Power consumption |

Throughput |

Dimension |

Product |

DLG100 Single screw extruder |

65kw |

49kw |

80~120kg/h |

26400×4000×3000mm |

Snack pelelts |

DG52-II Twin screw extruder |

86.6kw |

65kw |

100~150kg/h

|

35800×4000×3500mm |

Snack pelelts |

DG75-II Twin screw extruder |

131kw |

98kw |

250~350kg/h |

40300×5000×3500mm |

Snack pelelts |

Company Information

Established in 2012 ,but grows very fast in the recent 3 years , DG has gained a lot of good feedback and reputation worldwidly since we have exported our production lines to Russia, Turkey ,Slovakia ,Brazil ,Algeria, India ,Thailand ,Dominica,Urugay,Agentina,Yemen ,Palestine and so on .

We accept OEM orders, also can according to your needs to produce equipments. We have professional team to set up the equipments and also offer the technology and recipes.

Our Services

I. DG has professional team to design the whole production line according to your requirements

II. we also help our client to develop the old production line and carry out new products

III. Custiomized factory layout designed is provided by our professionals

IV. Overseas technicians are available to help the clients for installation and adjustment

V. 12 months warranty for the machines , 24 months for some parts

To ensure that our client can make good quality products, 2D 3D snack papad pellets manufacturing machine Machinery offers perferct turn-key project with professional team .

Turnkey project in Russia

I. To ensure long distance transportation ,DG uses best quality wooden case for the machines , besides , for the over-size machines ,we will fasten them reinforce them with steel frame.

II. The machines will be ready for disparch around 20~60 working days according to your requirements , some of the machines are available in stock , which can be made delivery once you placed the order .

FAQMore detailed information and the best price will be offered ,pls feel free to contact :

More production line

Pls click the following link to see the other snacks processing lines :

| 1 | Breakfast cereal corn flakes processing line |

| 2 | Extruded corn puff snacks processing line |

| 3 | 2D/ 3D snack pellets pocessing line |

| 4 | TVP/FVP soya protein products processing line |

| 5 | Pet food processing line |

| 6 | Nutritional powder / baby milk powder processing line |

| 7 | Fried wheaten snacks processing line |

| 8 | Tortilla chips processing line |

| 9 | Caramel popcorn processing line |

| 10 | Breadcrumbs processing line |