Hot Products ! ( Click the pictures to see the details )

------------------------------------------------------------------------------------------------------

Protein Meat Processing Line

I. Description

Protein Meat Processing Line is developed and manufactured on the basis of our experience combining with the advanced machines from foreign countries. This line takes soybean meal and peanut meal as main raw materials. After milling, mixing, extruding and cutting, the meal becomes layer fiber structure. With high nutrition, the finished products look and taste like meat, absorb oil and water easily, no cholesterol and animal fat, so it is widely used in meat products industry, fast food production, deepfreeze food production and all kinds of vegetarian snacks and food.

1. Raw Materials: Soybean Meal, Peanut Meal etc.

2. Products :Protein Meat Processing Line

3. Capacity: 120-150 KG/H, 250-300KG/H

4. Flow Chart: Fried Type: Mixing —Extrusion —Air Conveying —Baking

5. Voltage: 380V/50HZ/Three Phase, 220V/50HZ/Single Phase or Change As Rquired

6. Machines Materials: All the machines are made by food grade stainless steel.

II. Technical Parameters of Protein Meat Processing Line

Model | Installed Power | Main Motor Power | Output | Size(LXWXH) |

LT65P | 62.87kw | 45kw | 120-150kg/h | 3400*880*2300mm |

DL75 | 116kw | 75kw | 250-300kg/h | 4590*1160*2020mm |

III. Sample Picture

IV. Details & Features

1. Big Capacity Feeding Hopper, Variable Frequency Speed, Two Stages Mixing Wings ensure the Fast and Efficient Mixing and Feeding.

2. Main Motor Is Directly Connected With Bearing Box,Reducing Energy Loss And Saving Power.

3. Radiator Is Installed On Driving Part For Forces Cooling Effect, And It Ensures Extruder Operate Safely.

4. Linear Slide Face Cutting System, Strong Power, Variable Frequency Speed and Large Output.

5. Barrel With Water-cooled Circulation And Water Tubes With Copper Material.Wide Ranges Of Raw Materials Can Be Used For A Long Time.

6. Modular Circular Groove Screws, Available For Different Extrusion Rate Applications.

7. Unique Designed Round Barrels, Made by Hard Carbide Sleeve, Hard-wearing and Durable.

8. PLC Touching Screen Controller(Optional),Supporting Many Kinds Of Languages,Can Preserve Various Operating Procedure,Ensuring Easy Operation And Low Failure Rate.

Besides

Main Motor from Protein Meat Processing Line(CHINA), 75KW, Ensure Its Powerful Extrusion and Excellent Performance.

World-famous Brands Electronic Apparatus used in the Controller Box, make sure the Extrusion Process Perfect.

V. Service & Turnkey Solution

a.) Consultation service before, during,and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

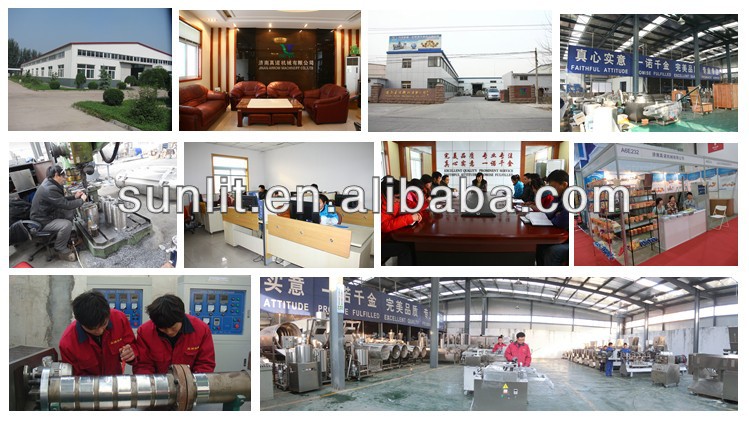

VI. Company Image

VII. Packaging

VIII. Glories of Company

IX. World Market