Our company has already exported countries

Asia { Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan }

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

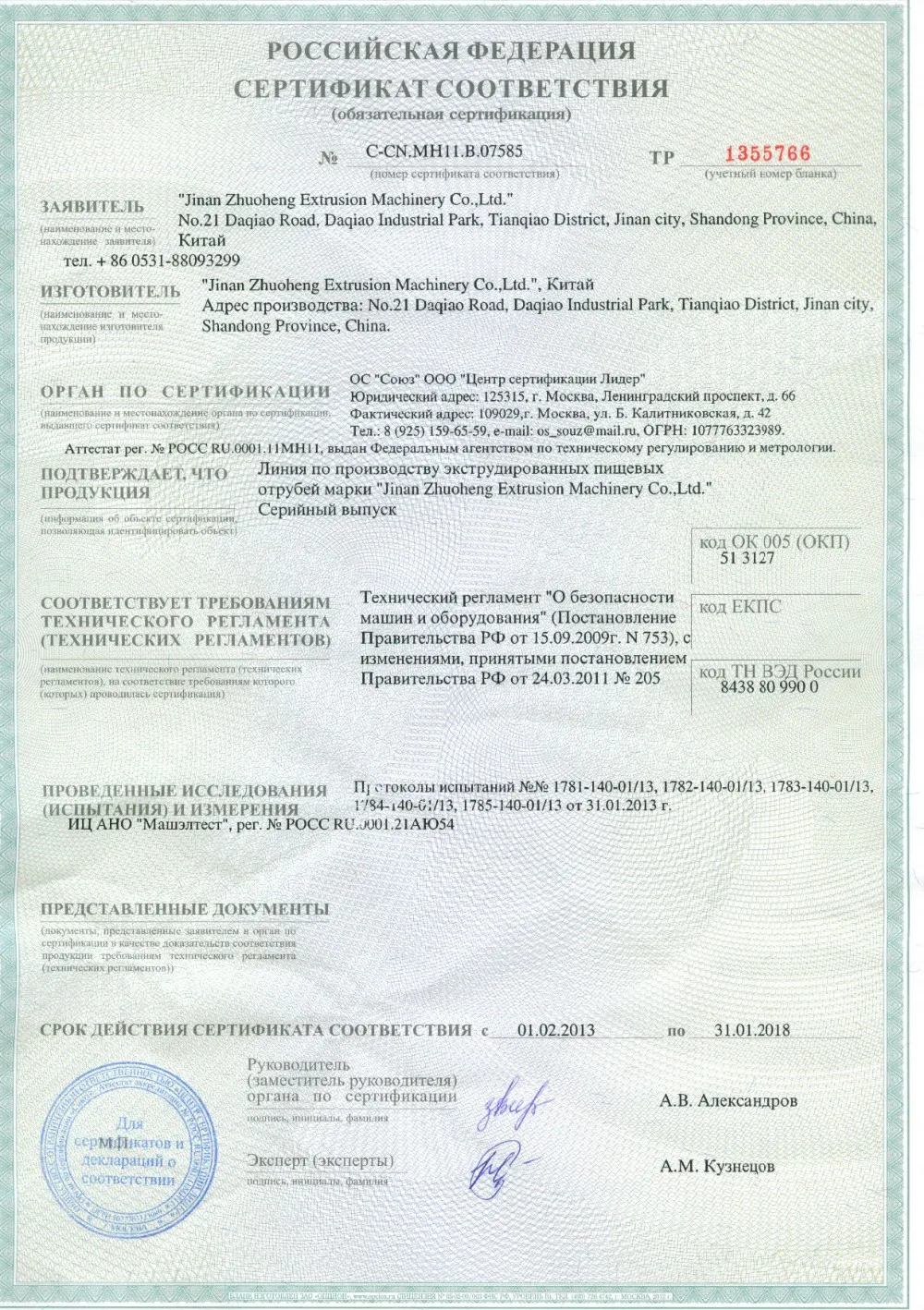

Europe { Russia, Bulgaria, Ukraine }

North America { Canada }

South America { Brazil, Bolivia }

Food extruder breakfast cereal cornflake machineia { New Zealand }

Zimbabwe

-------------------------------------------------------------Bangladesh

-------------------------------------------------------------

East Timor

-------------------------------------------------------------

Russia

-------------------------------------------------------------Uzbekistan

-------------------------------------------------------------

Ghana

-------------------------------------------------------------

Product DescriptionProfessional production, quality assurance, affordable, welcome to inquire,100% factory direct sales, look forward to building cooperate with you wholeheartedly!

Video Links On Food extruder breakfast cereal cornflake machine: https://www.Food extruder breakfast cereal cornflake machine.com/watch?v=47yWQzq136g&t=19s

Breakfast Cereal Food is a kind of crispy food which is processed by twin- screw extruder and takes grist as basic material. The majority are fiber flimsy, and either too sugary or too salty.Snacks food processing line can be directly extruded from the extruder, dryer and seasoner, we can produce all kinds of snacks and different shapes by adjusting

the dies from extruder.Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart

shape by adjusting the mould in the extruder.Raw Material : Corn Grits (Powder), wheat flour, rice flour, oat meal, other grain meals.

| Model | Installed power | Real power | Output | Dimension |

| ZH65 | 35 kw | 22kw | 150kg/h | 39000x1200x2200mm |

| ZH70 | 50kw | 37kw | 250kg/h | 41000x1500x2200mm |

| ZH85 | 110kw | 75kw | 500kg/h | 43000x3500x4300mm |

| ZH95 | 151kw | 110kw | 1ton/h | 4700x1900x4800mm |

| ZH135 | 425kw | 335kw | 3ton/h | 5200*2000*4800mm |

| ZH*** | ***kw | **kw | **ton/h | ****** |

Modle:ZH65 Twin-screw Extruder

Capacity: 120-150kg/h

Modle:ZH70 Twin-screw Extruder

Capacity: 200-250kg/h

Modle:ZH85 Twin-screw Extruder

Capacity: 300-500kg/h

Twin-Screw Extruders

In order to create a design with greater operating flexibility and with greater operational control, twin screw machines were developed. Twin-screw extruders can be co-rotating, counter-rotating, intermeshing or non-intermeshing in terms of basic designs. Co-rotating, intermeshing screw designs have dominated that scene as far as these extruders are concerned. This is because of relative ease of design and manufacture compared to counter-rotating designs.The screw design of twin-screw extruders can

affect operating efficiency and machine capability. Screw components in the feed section of the barrel can be single, double or even triple flight arrangements. With more flights intertwined on the shaft, the conveying capacity of the screw is reduced but the residence time distribution is lower. This promotes a first-in, first-out movement of the extrudate. However, double- and triple flighted screws produce more shear across the screw channel and therefore, improved processing uniformity.

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Provid the professional advice about the market, equipment, process, material, packing, etc.

* Assist you to choose equipment, design process flow, and perfect workshop layout. If needed, we can supply service in your factory.

* Make compensate plan to the material change according to your product, and perform the production at site.

* Specially design and manufacture machine, practice test, and provide relevant training as customer required.

* Provid reasonable packing and transportation plan, send technician to install, debug machine and train your workers.

* Two years guaranty time, preferentially supply spare parts.

* Design and process similar type of spare parts of import equipment.

Our company has already exported countries

Asia { Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan }

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine }

North America { Canada }

South America { Brazil, Bolivia }

Food extruder breakfast cereal cornflake machineia { New Zealand }

Zimbabwe

-------------------------------------------------------------Bangladesh

-------------------------------------------------------------

East Timor

-------------------------------------------------------------

Russia

-------------------------------------------------------------Uzbekistan

-------------------------------------------------------------

Ghana

-------------------------------------------------------------

Packing and Delivery

Packing

Outer Packing---Wooden case

Inner Packing----Wrapped with plastic film.

Delivery :

20 GP, 40 GP,40HP container by Land or Sea.

20-40 working days

Welcome to inquiry, your choice, our pleasure, your demand, we pursue.

Our company insist on the honest tenet, try our best to supply the good service for the home and overseas customers. Welcome to inquiry with e-mail or phone call.