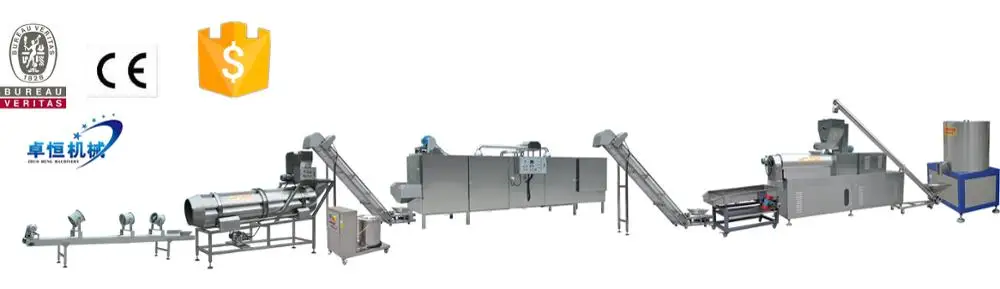

3d 2d fry snack pellets extruding machine

1. Description:

3d 2d fry snack pellets extruding machine adopts corn, rice, wheat, oat, barley etc as ingredients to make puffs snack. Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

2. Raw materials: adopts corn, rice, wheat, oat, barley etc as ingredients

3. Products: Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

5. Flow chart: Mixing system---Extrusion system---- -Drying system----Flavoring system---Packing system

6. Voltage in China: Three phases: 380V/50Hz, we can customize for clients according to customers’ Local voltage according to different countries

7. Technical Parameters: All the machines are made by stainless steel.

Model | Installed power | Real power | Output | Dimension |

ZH65 | 40 KW | 35 | 150kg/h | 39000x1200x2200mm |

ZH70 | 81.5kw | 53kw | 250kg/h | 41000x1500x2200mm |

ZH85 | 115kw | 76kw | 500kg/h | 43000x3500x4300mm |

ZH95 | 181kw | 117kw | 1ton/h | 4700x1900x4800mm |

8.Others machines

Our Services

8.Samples Show

Certifications

Certifications

Our Services

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service.

f.) Design: All the machines are elaborately designed by our mechanical engineers who are rich of experience in this field. We accept special design according to customer’s request.

g.) Processing & Assembling: Parts processing, assembly, testing are based on standard test.

h.) Trial Run: Each machine has to be tested before its deliver.

Packing&Delivery

Packing:

Outer Packing---Wooden case

Inner Packing----Wrapped with plastic film.

Delivery : 20-40 working days

FAQ

Q1. Are you a manufacturer or a trading company?

A: We are a professional manufacturer of food & feed extrusion machine.

We have own factory and R&D department. SGS has certified our company on site.

Q2. What is your payment terms?

A: Strongly recommend to use 3d pellet food machine china best/3d 2d fry snack pellets extruding machine’s Trade Assurance.

T/T :30% prepayment,70% before delivery. L/C at sight is available.

Other payment is negotiable

Q3.Do you offer guarantee for the products?

A: Yes, we offer 1-2 years warranty to our products.

Q4. What about the lead time?

A: Regular products:20-30 working days

Customizable products:30-40 working days.

Q5. Can you provide food or feed formula ?

A: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula

Q6. What after-services do you provide?

A: Send engineers for installation, trial running and training workers at customer's site.

Handling the problems occurred during use. Supply spare and wearing parts on discount.

Help customers to solve any other proble