1) This Big capacity pellet food processing line Is the newly designed for pellet food products both 2D and 3D shapes.

2) The raw materials are also wheat flour, potato starch, potato flour, corn satrch, cassava starch, etc.

3) This pellet extruder in big capacity is combined together two processes, one is pre-cooking the materials, and the other is extruding. With platform on the middle and safety guard on the top, it is easy to operate and observe during working.

4) Such extruder structure can make bigger capacity than the usual extruder, and also can deal with all kinds of raw materials for pellet food. Its multi-functional feature makes it more and more popular to those customers who want bigger capacity.

| Model | Installed power | Power consumption | Capacity | Dimension |

| 3D snack pellet process line | 132.2kw | 91.2kw | 400kg/h | 48000x4280x4550mm |

Detailed Images

Detailed Images

Main Features

Flour Mixer

Parameter

Driving power: 5.5kw

Stirrer diameter: 820mm

Stirrer speed: 300rpm

Capacity: 100kg/batch

Dimension: 1350*1050*1200mm

Description

This mixer is used to mix evenly all the materials in the formula.

Main Features

Screw Conveyor

Parameter

Driving motor power: 0.75kw

Stirring motor power: 1.1kw

Screw diameter: 104mm

Dimension: 30s on extruder

Description

This machine can send the mixed materials into the feeding hopper of extruder.

Machine Parts

VINCI Extruder

Parameter

Main motor power: 90kw (inveter adjust speed)

Dimension: 4700x4260x2580mm

Description

The Vinci engine is large puffing machine equipment. Combined with DAYI’s double-screw extruder and single-screw extruder is a high-tech research and development equipment. This equipment is mainly used for rotary extrusion processing, 3D pellet products.

Main Features

Diesel/Gas/Eletricity DryerParameter

Capacity: 250-400 kg/h optional

Dimension:13000×2100×2600mm

Effective width of net belt: 1m

Description

This machine can dry various extrusion snacks.such as 2D/3D pellet snacks food,puff snacks food,breakfast cereals,nutritional rice,pet food etc.

Our CompanyFryums 3D Oval Pappad Snack Pellets Machine

Our CompanyFryums 3D Oval Pappad Snack Pellets Machine

Fryums 3D Oval Pappad Snack Pellets Machine Extrusion Machinery Co.,LTD established in 1996, has always been the professional manufacturer and the leader for advanced and high efficient extrusion food machinery in this field all over the world.DAYI company congregates an expert team with twenty years experiences in this extrusion machinery industry, not only working hard to constantly researching extrusion technology, but also exploring food processes in order to benefit our clients producing creative food.

After years of exploration and research, our screw extrusion technique has been widely applied to produce the following products: Extursion Leisure snacks,breakfast cereal food and corn flakes, fried flour food, pellet food, bread crumb, textured soya protein and vegetarian meat, and pet food,etc.More than twenty production line can be chosen. And we can also provide customized service for special requirements.

Many infFryums 3D Oval Pappad Snack Pellets Machinetial large food companies and agent have chosen us as and set up worthy fellowship with us over 15 years, especially Oishi Foods Company in Japan, Ai Nasim food industries Co.,LTD in Jordan, Pt mayora indah tbk in Indonesia, Kinh Do Corporation in Vietnam, Universal robina corporation in Philippines, and the many agents like Vs tecnologia industrial in Brazil, Pakistan etc. Meantime, our machinery have been more and more popular with marketing of Malaysia, Indonesia, Philippines, Vietnam, Burma, Thailand, Japan, South Korea, India, Pakistan, Russia, Kazakhstan, Uzbekistan, Turkmenistan, Jordan, Yemen, Iran, Iraq, Egypt, South Africa, Algeria, Morocco, Czech, Poland, Brazil, Colombia, Australia, etc.

Typical Client

Acecook Company in Vietnam

Typical Client

Shanti Foods Co.,LTD in India.

Typical Client

Mitsuwa Co.,LTD In Japan

Attending Fair in Thailand

Attending Fair in Canton

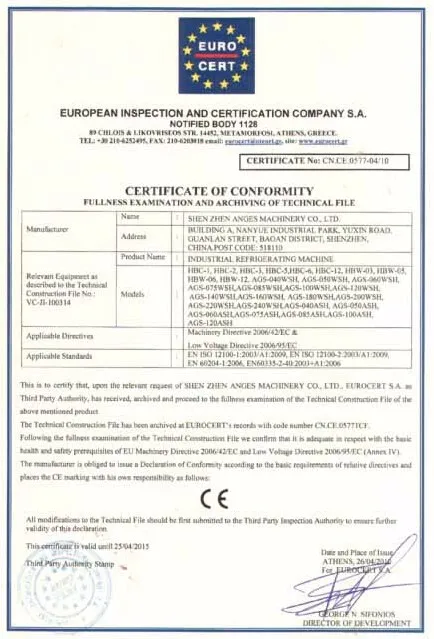

Certifications

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Contact Us Related Products

Related Products