100% factory direct sales, look forward to building cooperate with you wholeheartedly!

Our snack extrusion production line is designed to product expanded Ready-to-eat snacks with Twin-screw Extrusion technology.

This line can product various type snacks by changing dies, such as cheese balls, puffed corn snacks, chips, etc.

The shape, size, flavor of snacks can be customized as requirement.

Baking and frying are available.

| Model | Installed power | Real power | Output | Dimension |

| ZH65 | 35 kw | 22kw | 150kg/h | 39000x1200x2200mm |

| ZH70 | 50kw | 37kw | 250kg/h | 41000x1500x2200mm |

| ZH85 | 110kw | 75kw | 500kg/h | 43000x3500x4300mm |

| ZH95 | 151kw | 110kw | 1ton/h | 4700x1900x4800mm |

| ZH135 | 425kw | 335kw | 3ton/h | 5200*2000*4800mm |

| ZH*** | ***kw | **kw | **ton/h | ****** |

Twin-Screw Extruders

In order to create a design with greater operating flexibility and with greater operational control, twinscrew machines were developed. Twin-screw extruders can be co-rotating, counter-rotating, intermeshing or non-intermeshing in terms of basic designs. Co-rotating, intermeshing screw designs have dominated that scene as far as these extruders are concerned. This is because of relative ease of design and manufacture compared to counter-rotating designs.The screw design of twin-screw extruders can

affect operating efficiency and machine capability. Screw components in the feed section of the barrel can be single, double or even triple flight arrangements. With more flights intertwined on the shaft, the conveying capacity of the screw is reduced but the residence time distribution is lower. This promotes a first-in, first-out movement of the extrudate. However, double- and triple flighted screws produce more shear across the screw channel and therefore, improved processing uniformity.

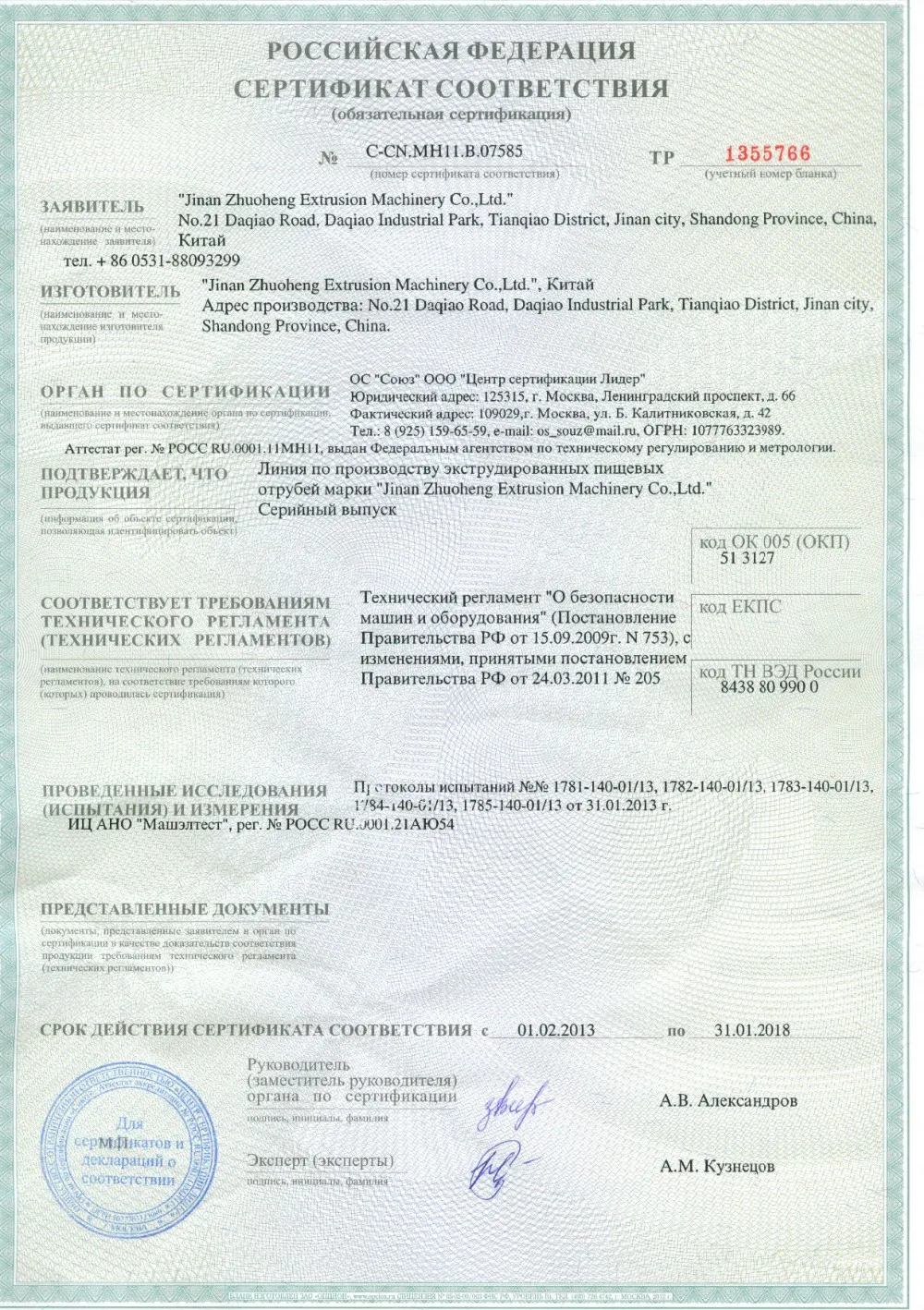

Certifications

Certifications

Our Company

Our Company

Our Service

Our Service

Packing & Delivery

Packing & Delivery

contect information

contect informationMiss Carrie Gao

Core Filling Snacks Cheese Puffs Machinery

Core Filling Snacks Cheese Puffs Machinery 2890594763

Core Filling Snacks Cheese Puffs Machinery 13793180286

Mobile Phone: +86 13793180286

WhatsApp/Viber/Imo/Core Filling Snacks Cheese Puffs Machinery +86 13793180286