Nik naks kurkure cheetos production plant making machine description:

Using corn grits as raw materials meanwhile mixing with water and oil,very crunchy and great in taste. Kurkure/Cheetos Nik naks kurkure cheetos production plant making machine is made by extrusion process. The Nik naks kurkure cheetos production plant making machine are moisturized in a vertical mixer with water, oil then feed to the Rotary Head Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The Kurkures Cheetos Nik naks snacks food is fried in cooking oil and then cooled before flavoring. Seasonings are sprayed on the kurkures Nik naks kurkure cheetos production plant making machine to improve their taste.

2.By adjusting the dies of the extruder, it can produce variety of shapes.

3. Flow chart: Mixing system---Extrusion system----Cutting system---Drying system---Frying system---Flavoring System --Packing system4.Capacity and power: find attached below form.

5.Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

6.Specification of the Nik naks kurkure cheetos production plant making machine:

| Model | DLG100 | DLG150 | |

| Install Power | 110KW | 180KW | |

| Consumption Power | 77KW | 126KW | |

| Output | 120-150KG/H | 220-250KG/H | |

| Dimension | 22000×1300×2200M | 26000×1300×2200M |

We are the biggest and professional food machine manufacturer, our aim is to be the market leader.

Our pasta production line.

The pasta cutting machine.

The pasta mould.

Detailed Images

Detailed Images

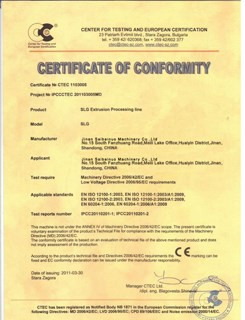

Certifications

Certifications

Our Service

Our Service

Pre-sale service:

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service:

1.Allocation chart as the buyer’s request will be supplied.

2.operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.

Related Products

Related Products

Baby food processing machine

Baby food processing machine96% Response Rate

Dog food processing machine

99% Response Rate

Textured soy protein machine

99% Response Rate