Pasta Machine/Italian Noodle Making Machinery

Introduction: Pasta Machine/Italian Noodle Making Machinery is a semi-manufactured dry product, made of dough, cooked opportunely using extrusion cooking technology, shaped and formed until reaching a humidity of less than 12%.

Rawmaterial:durum, maize starch, potato powder, potato starch, cassava starch or their mixture, etc.

Various shape: shell, spiral, square tube, etc.

Flow chart: Flour mixing-screw conveying-extruding-cutting-drying-cooling

Technical paramter

| Output | Installed Capacity | Actual Capacity | Voltage/Frequency | Dimension | Workers Required |

| 100-150kg/hr | 70kw | 45kw | 380v/50hz | 1700*500*300cm | 3-4 workers |

Why choose us?

1. Germany WEG motor, three years worldwide guarantee

2. PLC and touch screen to control the whole line, all faults will display on the touch screen

3. ABB or Schneider electric parts

4. NSK bearings

5. All parts touch with raw materials or final products are made of stainless steel 304

6. 24V operation voltage, assure the safety of operators

Certificate

Sample picture

Sample mold

Key Equipment Show

Pasta Machine/Italian Noodle Making MachineryLink:

https://www.Pasta Machine/Italian Noodle Making Machinery.com/watch?v=jRwUcFw9XRY&t=20s

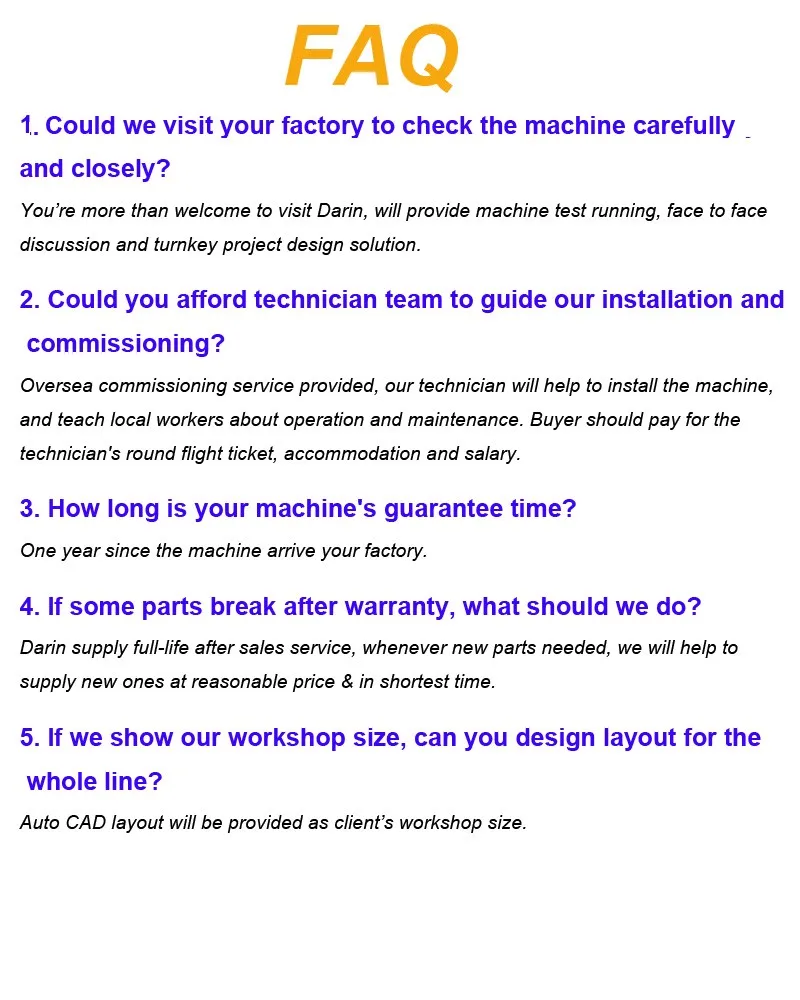

FAQ

Our Factory

Commissioning & After-sales Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After receiving firm order and down payment, we start to apply for the Visa to your country immediately; while the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line..

5. Our engineers can provide basic formula for the production, and help the customer to produce good quality food according customer’s detailed formula.

6. It normally costs 10-14 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

Delivery

Clients Visit

Exhibition

Contact Information