Pasta noodle Extruder machine /Pasta food production line/macaroni making machine for sale

Product Description

1). Description:

Italy pasta noodle macaroni food line is produced by single-screw extruder through extruding cooking; the pellet can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the pellet needs frying to get expanded.Technical Parameters

Output of macaroni: 100kg/h

Dimension 32 x 5 x 3m

Installed Capacity 65kw Workers Required 1-2 Workers

2). Raw materials:

Italy pasta noodle macaroni food line adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials

3). Products:

This line can be used to produce pellets, snacks, corn flakes by adjusting the moulds from extruder;

1.Mixer

function: Mix machine is used to mix raw materials, auxiliary materials and water or other materials of the machine, the speed is moderate, mixed evenly.

features:1.The contact part of the product material is made of stainless steel material.

2. Discharge holes are open new processing design, good sealing, avoid leakage of material.

2.Screw hoister

function: Using the mix mix machine screw mechanism of raw materials to the host in the feeder.

3.Single screw extruder

features:1.Use of advanced frequency control skills, work stable and less power consumption.

2.Screw by alloy steel, has a High capacity Pasta noodle making machine Italian Pasta product line service life.

3.Automatic heating control system, easy to work and more accurate parameters.

4.Device configuration water cycle temperature control system.

5.Feeding motor, host equipment, rotary cutting machine adopts frequency control of motor speed.

6.Configure a small single rod extrusion machine, the realization of secondary cure, product curing effect is good.

4. Pulling & cutting

features:1.Cutting knife is used to cut rectangular pipe, pipe.

2.Traction cutting machine has two parts: to cut off the system and transmission system.

3.Equipment operation is simple, the use of frequency control.

4.Commonly used in long, long tube shape small food, such as salad, French fries, pipe, circle half swelling or not puffed food.

5.Hoister

1.Hoist communicate food from low to high, according to the process; Decided to lift height and horizontal distance.

2.Hoist can be divided into large and small according to the height of the hoist and horizontal distance.

3.Hoisting machine is commonly used in : the semi-finished product from the host ascending to the next working procedure of lifting device.

4.Conveyor belt can be divided into rubber belt and stainless steel.

6.Hot Air Dryer

function:

It can be used to bake dry food. The oven can bake a variety of inflating food, pet food, use/TSP food, peanut, nuts, chew nut and so on.

features:

1.The oven has compact structure, small occupies area, large dry, small area, slight heat radiation, high thermal efficiency.

2.Belt and use stainless steel heat preservation, suitable for food industry.

3.Can control the running speed of the oven belt network(frequency).

4.Temperature can control the arbitrary and design according to the need.

5.Heating pipe heating way, raise and lower the temperature quickly, thermal intertia small, high thermal efficiency.

6.Speed of net belt with accurate temperature control device.

7.Double roller chain and chain drive make stable and smooth running.

8.At the bottom of the sliding plate dryer is easy to clean.

9.Fit for their extrusion snacks, nutritional powder, bread crumbs, pet food, nutrition, rice, dried fruit, soybean protein, etc.

Packing&Delivery

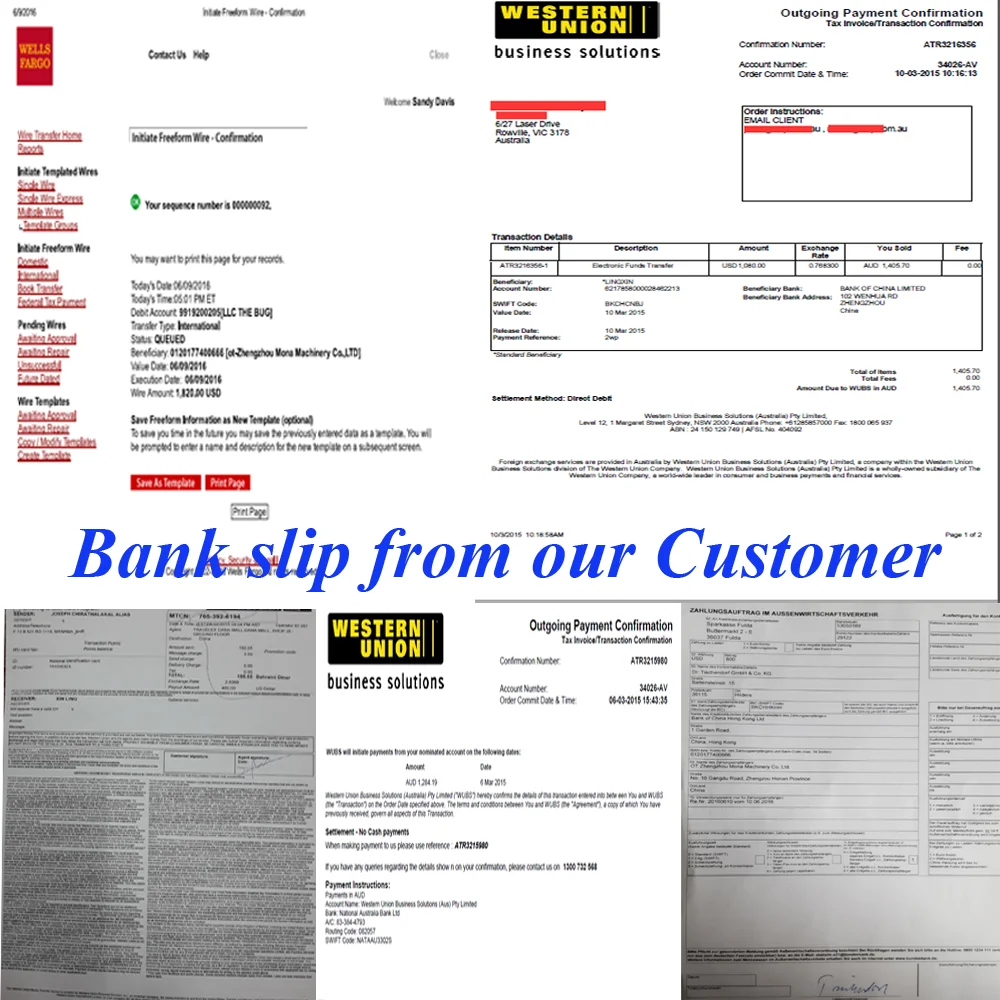

Bank slip