Our Hot Products! Full Automatic New Condition PFull Automatic New Condition Panko bread crumbs extrusion line bread crumbs extrusion line

1) Introduction of Full Automatic New Condition PFull Automatic New Condition Panko bread crumbs extrusion line bread crumbs extrusion line

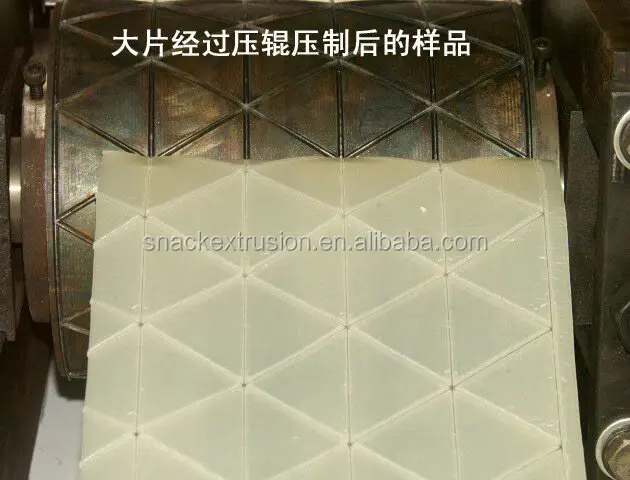

This Hoat sale bread crumb grinder machine uses rice powder and corn powder as main raw materials which are extruded, expanded, and pressed to be the exquisite thin chip, and then punched into round,, triangle, hexagon, etc. shapes by the punching shaper, after dried and seasoned, the finished crispy thin chip with different tastes come into being. This process line gets extruding curing, steaming, and shaping together, making the production simplified with low consumption and high automation. The grinded waste chip can be reused which has reduced the production cost. This process line is the best environment protection equipment.

Flour mixer→conveyor →extruder→stamping machine →fryer –flavoring line

big Full Automatic New Condition PFull Automatic New Condition Panko bread crumbs extrusion line bread crumbs extrusion line

Full Automatic New Condition PFull Automatic New Condition Panko bread crumbs extrusion line bread crumbs extrusion line

v 1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self- cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

v 2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

v 3. Gearbox with automatic lubrication function, extending gear life.

v 4. World famous brand Full Automatic New Condition Panko bread crumbs extrusion line main motor, guaranteeing good quality

v 5. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

v 6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

2)technical parameters of Full Automatic New Condition PFull Automatic New Condition Panko bread crumbs extrusion line bread crumbs extrusion line

Model | Installation power | Consumption power | Capacity | Dimension (MM) |

ZH65DJ | 61 kw | 40 kw | 150 kg/h | 21000*1500*2600 |

ZH75A | 81 kw | 56 kw | 250~300kg/h | 26000*5000*2400 |

3)pictures of running Full Automatic New Condition PFull Automatic New Condition Panko bread crumbs extrusion line bread crumbs extrusion line

4)samples of Full Automatic New Condition PFull Automatic New Condition Panko bread crumbs extrusion line bread crumbs extrusion line

5)spare parts of Full Automatic New Condition PFull Automatic New Condition Panko bread crumbs extrusion line bread crumbs extrusion line

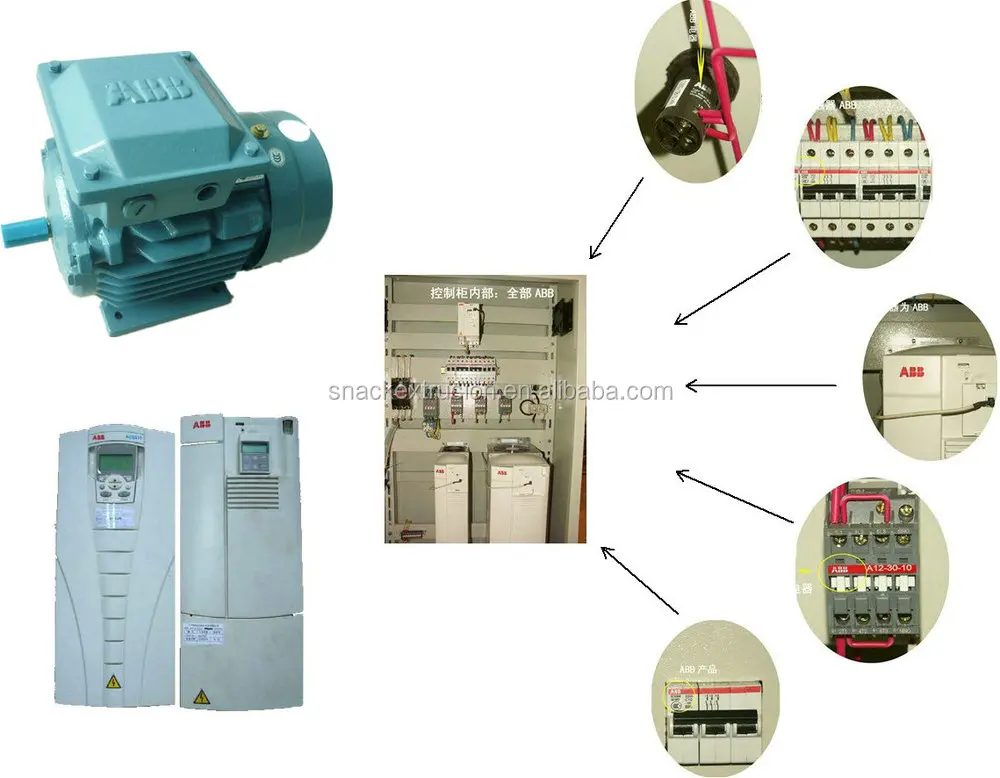

6)Relay details all ABB

7) Our parts store

we have all parts of machines here

8)Sample display cabinet

10) Certification

We provide the following service free of charge

1. provide optimized and advantage solution for customer

2. service on raw materials, flavor select

3. workshop , water, gas, electricity design for customer

4. management of shipment

5. training of equipment maintenance and operating work

6. provide new production techniques and formulas

7. Provide maintenance service within 1 year complete warrantee and lifetime

8 .2 technician will be sent to customer factory after shippment for installation

Packaging & ShippingWith full wooden package in container.Packing shall ensure the safety of Goods during its transportation and loading by Seller and unloading in the country of Buyer

factory picture

Full Automatic New Condition Panko bread crumbs extrusion line have well-equipped testing facilities and strong technical force in food machinery filed and other industrial.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

CONTACT US