Bread crumbs Extrusion Production Line

Product Description

1.Bread crumbs are widely used to coat the surface of fried food as a food additive. Such as fried chicken, drumstick, shrimp, onion rings, etc.

The long and sliver shaped breadcrumbs are of porous structure inside.

After frying, the crumbs become straight up bit by bit. They are not only puffed and nice in appearance but also crisp and delicate in taste.

2. Breadcrumbs processing line is specially designed and developed according to market demand.

The whole line can be finished from the raw materials, extrusion, drying to finished products automatically.

A . Production line details

| Capacity | 120kg-1000kg | ||

| Power Supply | Based on 380V 50 Hz 3 phase. Customized according to your local power. | ||

| Machine details | 1.Stainless steel,:201, 304, 316, on request 2. Electric parts can be ABB, Delta, Fuji, Omron, cheap price breadcrumbs production machinery; Famous brand as your demand. | ||

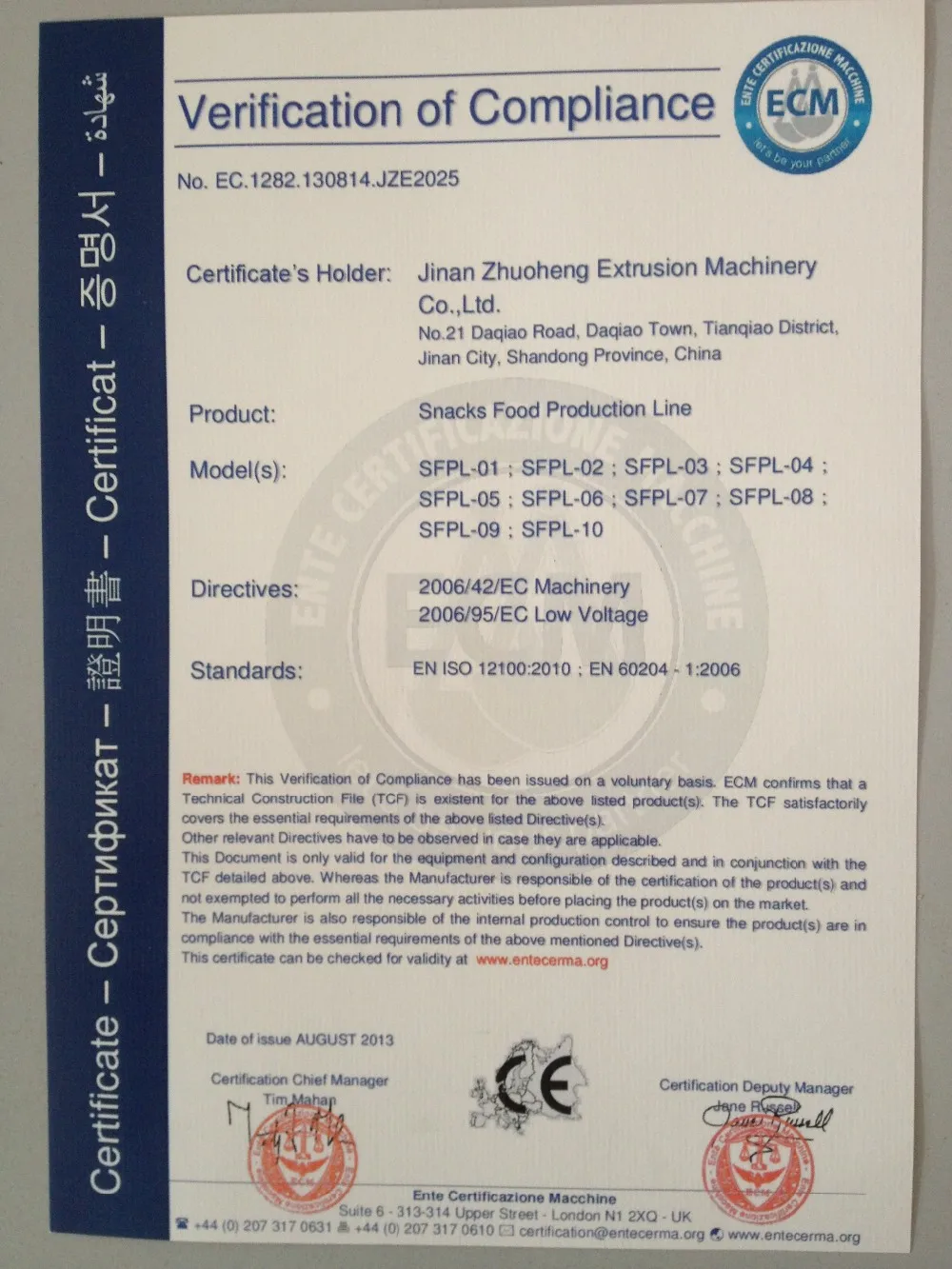

| Certificate | CE,GOST,TUV,BV | ||

| Raw Material | Wheat flour, etc. | ||

| Products Color | White, Yellow | ||

| Products type | Particle, needle etc. | ||

B. Advantages

1.The screw material: Alloy steel (38CrMoAL) by nitriding process. High strength and wear-resting.

With good self-cleaning ability, it’s unnecessary to remove the barrel and screws for cleaning.

2.SIMENS (China) Motor

3.It adopts speed-adjusted converter on feeding system, extrusion system and cutting system.

Food grade stainless steel twin screw feeding device guarantees stable materials feeding in the whole food process.

4.Adopted the Delta inverters, ensure the extruder better running.

5.The gearbox has automatic lubrication function, which prolong service life of gears.

6.Cutting knife is fixed in the die head seat, rotary cutting driven by V-belt.

C .Technical Parameters

| Model | Installed power | Real power | Capacity | Dimension |

| ZH65 | 45kw | 22kw | 120-150kg/h | 39000x1200x2200mm |

| ZH70 | 50kw | 37kw | 280-320kg/h | 41000x1500x2200mm |

| ZH85 | 110kw | 75kw | 450-550kg/h | 43000x3500x4300mm |

| ZH95 | 151kw | 110kw | 850-1000 kg/h | 4700x1900x4800mm |

D.Production process

Mixing Raw material -----Extruding----Drying--- Crushing---Screening---Packing

Our Company

Our Company

Assembly Workshop

Our WorkshopShowing Workshop

Show finished machines

Office

Our office

Team

Our Team

Meeting Room

Meeting with customers.

Sample Room

Showing products produced by our machine.Certifications

Our customers

Our customers Our company has already exported countries

Asia { Thailand, Indonesia, East Timor, South Korea, India, Bangladesh, Iran, Saudi Arabic, Turkey, Iraq, Israel, Kazakhstan, Tajikistan, Uzbekistan, Turkmenistan }

Africa { Nigeria, Benin, Algeria, Egypt, Ethiopia, Ghana, Namibia, Uganda, Zimbabwe}

Europe { Russia, Bulgaria, Ukraine }

North America { Canada }

South America { Brazil, Bolivia }

cheap price breadcrumbs production machineryia { New Zealand }

Our service

Our service 1. We will give detailed introduction of the fish feed making line according to the client capacity requirement.

2. Share any information about the fish feed making line that the clients need, like detaield pictures, video,etc

3. Design fish feed making line for client according to different requirements.

4. Help the clients to do suitable formulation.

5. Give detailed instruction manual and video to help the client operation the fish feed making line.

6. We could send engineers to clients' local places for installation, debugging, and taining.

Welcome to our factory, if you are interested in our products.

We could supply you with high quality machines and good after-sales service.

Q1. Are you a manufacturer or a trading company?

A: We are a professional manufacturer of food & feed extrusion machine.

We have own factory and R&D department. SGS has certified our company on site.

Q2. What is your payment terms?

A: Strongly recommend to use cheap price breadcrumbs production machinery’s Trade Assurance.

T/T :30% prepayment,70% before delivery. L/C at sight is available.

Other payment is negotiable

Q3.Do you offer guarantee for the products?

A: Yes, we offer 1-2 years warranty to our products.

Q4. What about the lead time?

A: Regular products:20-30 working days

Customizable products:30-40 working days.

Q5. Can you provide food or feed formula ?

A: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q6. What after-services do you provide?

A: Send engineers for installation, trial running and training workers at customer's site.

Handling the problems occurred during use. Supply spare and wearing parts on discount.

Help customers to solve any other problems .

Packing:

Outer Packing---Wooden case

Inner Packing----Wrapped with plastic film.

Delivery : 20-40 working days