Mini modified starch drying machine design

Product Description

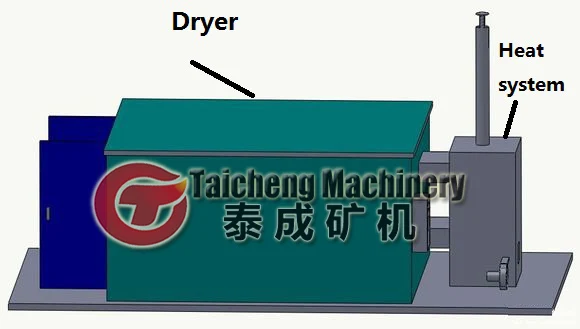

Modified starch drying machine Introduction

This drying machine is widely used for the heating and dehumidification of raw materials and products in pharmaceutical, chemical, foodstuff, light and heavy industries. Eapecially for the fruit and vegetable food processings. Suit for factory,restaurant,school ,farm and so on.

Modified starch drying machine Application

1. Our this series stainless steel multi-function drying machine can dry all kinds of materials,such as meat,vegetables,fruits,spice,sea cucumber,herbs,

onions,gingers,tea leaves etc.

2. Used for drying Chinese herbal pieces, dissolved medicines, powder,crude drug,Drug packing bottle,pigment,dyestuff,dehydrated vegetables ,food, plastic resin, paper,

leather,wool, electrical apparatus element ,salts,catalyst etc.

3.Suit for factory,restaurant,school ,farm and so on.

4.suitable for all kinds of food material,seafood drying such as seaweed, dried fish, shrimp, squid, fish fillet, sea cucumber, abalone,also apply to the bamboo shoot, mushroom, spices,garlic, tea leaf, flowers, sophora flower bud, dried fruits, vegetables, mushrooms, sweet potato, corn, peas, beans, coconut, nuts, dried black fungus and other agricultural and sideline products, as well as the honeysuckle, chrysanthemum, rhubarb, red sage root, ginseng and other Chinese herbal medicine drying.

Modified starch drying machine Working Principle

This dryer was upgraded and regenerated for several times and has reached advanced level both at home and all over the world. After being filtered by the primary filter fixed at the air inlet, the clean air will be blown into the drying chamber and flow towards the electrical heater. Then the heated air will be evenly distributed to each layer of trays. The hot air penetrates through the raw material via the holes punched at the tray bottom to evaporate the moisture from the raw material. Some of the moisture will be exhausted through the exhaust vent and new fresh air will be brought in to supplement the circulation air.

Modified starch drying machine charcteristics :

1. New designed energy saving dryer with two times waste heat recovery.Low working noise ,stable working condition,automatic temperature control system,easy to install and maintain.

2.automatic temperature control system,easy to install and maintain.

3. The drying oven can be made of carbon steel, stainless steel according to the required.

4. The final water content can be <1%.

5. Most of hot air circles in the sealed oven,high heating efficiency and energy-saving.

6. Having forced ventilation function and equipped with adjustable wind separator plates, high drying evenness.

7.Dryer machine adopts special design, making the heating efficiency 3-7% increase compared to the current 35-45%, the highest thermal efficiency can reach 50%.

8.During drying, the material does not craze, does not distortions, non-discoloring, never degenerate, non-oxidize, drying completely, with good rehydration, keep nutrient content;

9. Automatic control system and computer control system for your choice.

10. Having forced ventilation function and equipped with adjustable plates, drying evenly.

11.Temperature allowed with50°C-250°C according to your requirements. Stable operation without being infMini modified starch drying machine designced by weather

12. You can freely choose steam,gas as the heating source.

CUSTOMER SITE

Modified starch drying machine Technical Parameter:

Model | Number of Trolley | Power(kw) | Capacity per batch | Drying time per batch |

TCBD-2 | 2 | 1.75 | 300-400 kg | 5-8 hours |

TCBD-4 | 4 | 2.24 | 400-600 kg | 5-8 hours |

TCBD-6 | 6 | 3.16 | 600-1000 kg | 5-8 hours |

TCBD-12 | 12 | 4.05 | 2500-4000 kg | 5-8 hours |

TCBD-24 | 24 | 6.52 | 5000-8000 kg | 5-8 hours |

FAQ

1.what is the raw material?

2.what is the moisture before drying and after drying?

3.what is the capacity per hour?

4.Heat source? (firewood,coal ,heat gas ,)

5.Where the final dry material used for ?

Packaging & Shipping

Packaging:Standard export containers. Bare main machine, motors and small parts are packed in wooden cases. We can also pack them according to your requirement.

Countact Us

Whatsapp:+8613783554319

Certifications

Our Services

Service and Solutions Pre-sale services: We can provide you with project design, process design, suitable purchase program for your equipment.Also design and manufacture products based on your specific needs, to train your technical personnel.

Sale: We will accompany you to complete the equipment inspection, construction plan and assist in the development process in detail.After Sale Service: We send technicians to the scene to guide the equipment installation, commissioning and training your operating personnel.Company Information

Zhengzhou Mini modified starch drying machine design Mining Machinery Co., Ltd. is a large-scale joint-stock enterprise, focas on the production of heavy mining machinery, integrated with scientific research, production and sales. The company is located in zhengzhou national hi-tech industrial development zone, covers an area of 50,000 square meters, with 15,000 square meters two standardized heavy industrial plant, more than 160 sets all kinds of large and medium sized metal processing, welding, assembly equipment.

The company attaches great importance to international technical exchanges and cooperation, has introduced advanced technology and craft from United States, Germany, Australia and other countries, establishes the international advanced production lines and first-class modern testing base.