Introduction of Pregelatinized Starch Making Machine:

With this machine you can get Pregelatinization Starch, modified starch, API Drilling Starch, oxidized starch and so on

API Drilling Starch is an effective and economical fluid loss agent in water based drilling fluids, which is a starch derivative. It is not bacterial degradation when at 120, environmentally acceptable and non-toxic. Modified Starch can produce a thin, slick, tough filter cake and promotes faster penetration rates with reducer friction. It can be used in all kinds of drilling fluid systems.

Original starch is dealed by some method and chande the original physical and chemical characteristic.

Modified starch is a kind of starch be modifed characters.This kind of starch own the physical and chemical characteristic. It is added into food formulation and make the food process and usage have a better performance.As long as it is edible, its physiologic function is same to common starch and enfant can eat it.

Raw materials: corn starch, cassava starch, potato starch,maize starch,tapioca starch

Products: oil drilling starch, Pre-gelatinized starch

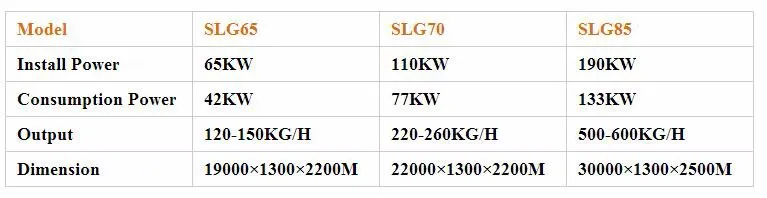

Capacity: 120--150kg/h , 220-260 kg/h , 500-600kg/h

Flow chart:Mixer---Screw conveyor---Twin-screw extruder---Air conveyor---Dryer---Air conveyor---Milling system

Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

Machines materials: All the machines are made by stainless.

The specification of the Modified starch machine:

The modified starch machine:

Simple pictures

Simple pictures

The drawing of the modified starch machine:

Characteristics:

Characteristics:a.Various models to meet different output capacity requirements.

b.Flexible configurations to meet different produce, budget and workshop layout requirement.

c.Vast raw material range to produce different final products by only one production line.

d.High automation and accurate control system to save labor cost and improve the quality of final products.

e.Independent temperature control system is able to realize zone temperature control, electronic induction, accurate & visual digital display.

f.Feeding system without material returning. It is unnecessary to clean barrel and screw in case of restarting or material replacement.

g.Screw adopts high-performance nitride alloy steel with strong wear-resistance and Pregelatinized Starch Making Machine service life.

h.Food-grade stainless steel. Neatness and easy clean.

Finished products and ready for shipment:

Finished products and ready for shipment:

Certifications

Certifications

Detailed Images

Detailed Images

Machine Parts

Name: Mixer

Brand: Saibainuo

Motor Power: 4KW

Demision: 1.1×0.6×1.4M

Speed: 400rpm

Function:To mix the raw material like rice flour, corn flour, wheat flour, water ,sugar with high speed

Main Features

Name: Dryer

Function:

There are three layer inside,each layer is 5 meters long, it can save space and energy. Electricity heating,used to bake and dry food.

Features:

The net belt running speed can be controlled by Inverter, to change the food drying time in the dryer.Heating adopts the electric heat tube.It has automatic temperature Control system.The belt and the cover are all stainless steel

Machine Parts

Name: Elevator

Function:

elevator conveys the food from the discharge-port of oven to the feed-charge port of roller.

Features:

No leaking material and pollution PVC conveyor belt suitable for the long distance conveying can adjust the height by holder stand

Main Features

Name: Air conveyer

Functions:

1).conveys the food by the wind-force from the blower.

2).suitable for long distance conveying

Features:

Low energy-consumption, high efficiency.

It use high pressure blower to send food, It is more effective than normal pressure blower.

Our Service

Our Service

Our Services:

a. We can keep product design in the same level with internationally advanced technology consistently.

b. We have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production.

c. We can guarantee customers superior quality machines up to design requirements and perfect working state.

d. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

e. We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

f. We provide 1 year complete Guarantee and life-time maintenance service.

If you have any needs or enquiries, please feel free to contact me. Thank you very much!

Packaging & Shipping:

1).packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film.Finaly pack them with wooden case.

2).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port

Breakfast cereal machine

98.8% Response Rate

Kurkures making machine

99.2% Response Rate

Puff snacks food machine

97.8% Response Rate