Brand new 250Kg per hour Rice cracker production line

Brand new 250Kg per hour Rice cracker production line company has agreed the ISO9001:2008 guarantee, also given several patents rights. In addition, we also get into the CE guarantee system. High resistance steel structure, is painted special paint to conserve for oxidize and its structure is strengthened for vibration. All surfaces that contact food, in our machine, are aluminum and stainless steel. Main structure is placed on elevated prop; all lines are provided against direct contact to floor.

Manufacturing standards and characteristics of the Brand new 250Kg per hour Rice cracker production line:

· Full automaticPLC control system, all of the control elements adopt international well-known brand, high precision and reliable.

· There is an observation window with illuminator on the Baking oven available for watching during operation.

· Provide whole factory planning, personnel training ,product material analysisand technological formulation.

| Production capacity | 2.5 tons/day | 5 tons/day | 7.5 tons/day | 10 tons/day | 12 tons/day |

| The total installed power | 90 KW | 150 KW | 190 KW | 230 KW | 250 KW |

| Machine length | 50 M | 60 M | 80 M | 100 M | 140 M |

1. Samples made by our Brand new 250Kg per hour Rice cracker production line

Our machine can make rice cracker and salted senbei, the demensions for crackers could be changed according to the mould.

2. Parts showing for Brand new 250Kg per hour Rice cracker production line

3.Brand new 250Kg per hour Rice cracker production line running in our customers factory

The basic process:

Steeping and milling—digester—extrusion—forming—first dryer—colling—second dryer—baking—spray oil—seasoning

—spray sugar—third dryer—packing

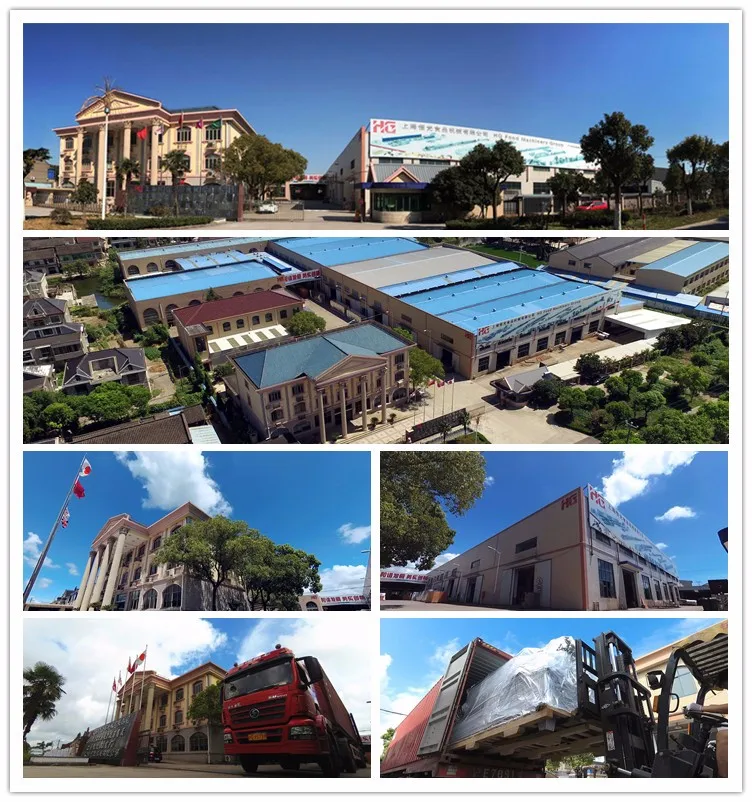

4. Work shop show

The all parts of our machine besides the electric components are made by ourself , we have our own machining work shop ,electric cabinet workshop ,Cuting and installation workshop.

5.Packing and shipping

we use wooden packing for every parts to keep the machine in good condtion.

6.Qualifications and certifications

Our factory has passed the ISO9001:2000 system, the machines are CE and CQC approved. Some of our machines have been use for more than 10 years, still running in a stable condition.

We have more than 300 patents,such as Potato chips frying pot patent / Baked potato chips production line

patent / Cakes core injection mechanism patent / Cakes demoulding transposing patent / Full automatic center

filling slice cake device patent / Gas tunnel oven patent / Tunnel mul-layer sterilization device patent / Barbecue puffing oven patent / Food conveyor patent / Egg roll cutting device patent etc.

6.Qualifications and certifications

With reliable quality and hearty services, we have exported to U.S.A., Austrilia, Russia, Poland,Lebanon, Uzibekistan, Morocco, India, Bangladesh, Sri Lanka, Iran, Libya, U.A.E., Saudi Arabia, Syria, Iraq, Vietnam,Japan,Malaysia, Burma,Pakistan, Indonesia, Mongolia, Egypt, Algeria, Ethiopia, Tunisia, Brazil, Venezuela, etc.

7.More information please contact us online or send us a inquiry.

We warmly welcome you come to Shanghai and visit our factories here, and establish long-term cooperation with you in the future!

Shanghai HG (HengGuang) Food Machinery Group has established for nearly 40 years, expertise in food machines manufacturering. As a group, we have 4 machinery factories, one food experiment facory, and an international trading company in Shanghai, we are also supporting the Shanghai Second Polytechnic University.

We are one of the earliest and manufacturer in China to make food machines, and have 4 machinery factories and 1 food factory in Shanghai. With nearly 40 years' experience, we have served many large companies, such as, Pringles in USA, Lina Group in Iran, Britannia in India, CBL in Sri Lanka, and Dali Group, the biggest food company in China, 85% of their production lines are from our factory. You will get 100% guarantee from our factory!