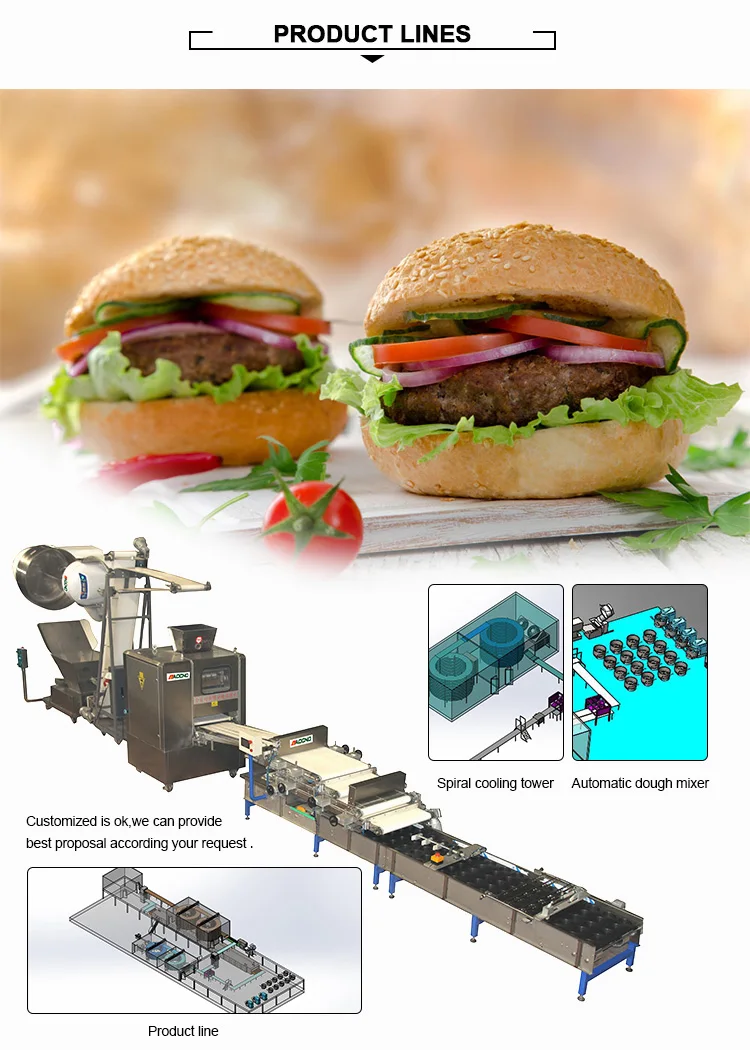

automatice toast bread cake bakery equipment production line

Professional engineer teams will made best layout proposal for your request

Spiral Cooling tower | |

Component | Superior quality imported automatice toast bread cake bakery equipment production line Frequency converter,SEW reduction gears,Schneider electronic elements |

Material | The Conveyor Belt is made of stainless steel 304,and the frame was made of SS304 or SS201 square steel tubes |

Belt width range | 200 mm-800 mm |

Belt length range | Single tower 100m-300m |

Tower diameter range | 2-5.5m |

Layer height | Max height is 6 meters |

Tower Layer range | 5-30 layer |

Entrance&exit direction | Low inlet high exit high inlet low exit double inlet & double exit Three inlet & three exit Elliptic type |

Automatic tipping dough mixer | ||||||

Model | Flour(kg) | Dough(kg) | water(kg) | Size(mm) | MOQ(set) | Delivery time |

ACN-MT130 | 15-80kg | 24-130kg | 9-50kg | 1635*1280*1615 |

1 set |

7 days |

ACN-MT160 | 20-100kg | 32-160kg | 12-60kg | 1635*1300*1625mm | ||

ACN-MT200 | 25-125kg | 40-200kg | 15-75kg | 1725*1340*1625mm | ||

1.What is the guarantee period?

The ordinary type is 12 month,luxury one is 24 months.If any component is damaged in guarantee period,we will send same free by air and guide for installation.

2.Do you supply overseas installation?how many days you need?

Yes.we supply overseas installation?Generally,whole production line needs 7 days.

3.What is the payment?

Less than 10,000 USD is 100% T/T in advance

More than 10,000 USD is 50 % T/T in advance and balance is before shipment.

We can also accept 100% irrevocable L/C at sight and Western Union.

4.I want a bread production line,why I choose you?

We have been in this line for over 30 years,we can supply one-stop service ,with professional engineers team,exact layout proposal,and quality machinery.

5.What is your difference with other manufacturer?

Self-owned factories and bakery shops made us more professional and knows what you want.