Beaten biscuit machine/automatic cookie biscuit production line

Hot Products ! ( Click the pictures to see the details )

Product Description

1. Description:

The main raw material is wheat biscuit flour, then add sugar, oil, eggs, dairy products and other accessories. Depending on the formulation and production process, the sweet biscuit and cookies can be divided into two categories biscuit.

Biscuit is characterized by a more concave shape impression flower needle surface. Products smooth surface, cross-section structure level, there is a sense of time chewing crunchy, chewy, crunchy its unique characteristics. Compare biscuit with sugar and low fat cakes of bread. Generally with 30% of what the amount of sugar, 20% less fuel consumption. Cookie is characterized by multi-convex shape impression flower pattern evident, fine structure, 14% to 30% of the amount of flour. Special products loose some sweet, fat amount up to 50%.

Cookie: wheat flour, sugar, oil as the main raw material, adding a leavening agent, and other accessories, the cold powder technology blending flour, roll, roll printing or punch, baked into a convex shape, mostly flowers, cross-sectional structure rendered porous tissue, loose texture of baked goods. Such as butter cookies, Congxiang crackers, sesame crackers, eggs, biscuit and so on.

Biscuit: wheat flour, sugar, oil as the main raw material, adding osteoporosis agents, modifiers and other materials, the heat transfer process powder pink, roll, roll cutting or printing, graphic baking made mostly spend concave appearance smooth, smooth surface, there are needle, section layered, crunchy baked goods. Such as milk cake, vanilla cake, egg flavor cake, pie Mary, Boston cake.

A completely new-style biscuit machine, reliable quality, automated production, the production of various kinds of biscuit mold , customized according to your needs. Butter cookies, thin biscuit, oreo biscuit ,milk and cookies ,animal crackers, vegetable biscuits etc.

2. Raw materials:

Adopts wheat flour,water,milk,sugar,oil etc as ingredients.We will offer specific formula

after choosing machine.

3. Products:

Variety shapes are available for round, triangle, square, long, and flower shape by

adjusting the mould in the extruder.

4. Output:

50kg/h, 100kg/h, 200kg/h 400kg/h

5. Flow chart:

Double maker---Major Machine---Comtroller---Toastingoven---Sprayer---Cooling Machine .

6. Voltage:

in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries.

7. Technical Parameters:

model | Input voltage | power | output | weight | dimension |

GYB225 | 380v/50hz | 28.5kw | 50kg/hr | 1500kg | 18x0.6x1.5m |

GYB280 | 380v/50hz | 56kw | 100kg/hr | 2500kg | 26x0.8x1.5m |

GYB400 | 380v/50hz | 120kw | 200kg/hr | 4000kg | 45x1.0x1.5m |

GYB600 | 380v/50hz | 200kw | 400kg/hr | 10000kg | 70x1.2x1.75m |

8.Machinery and installations:

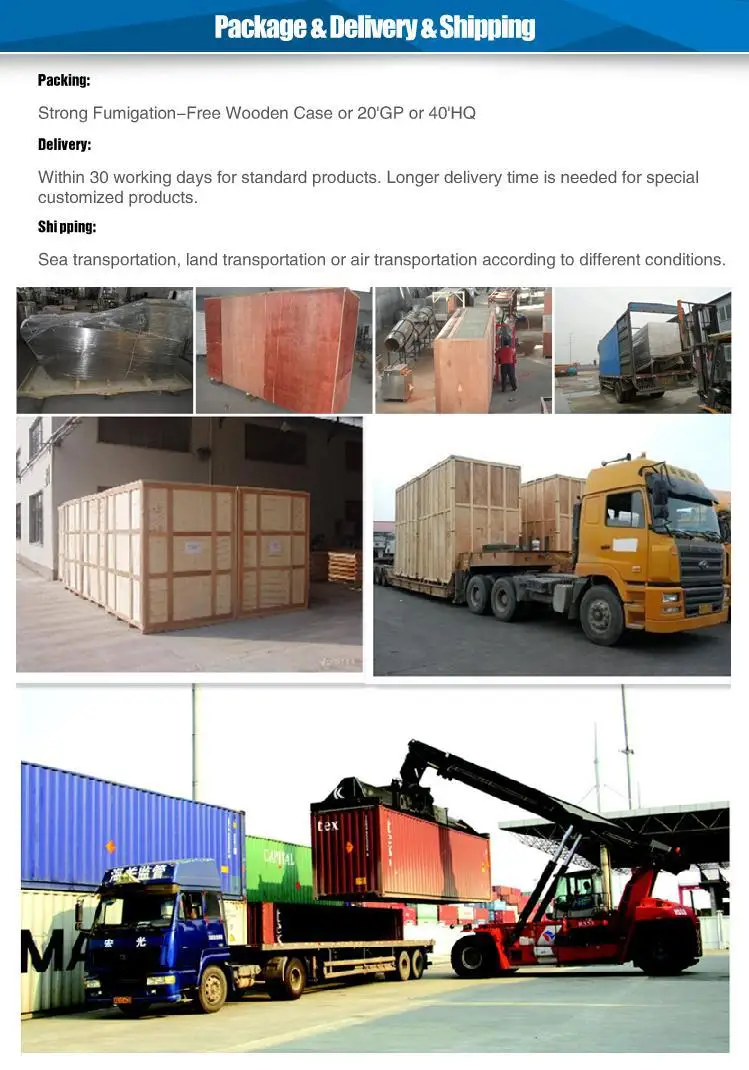

Packaging & Shipping

China full automatic biscuits processing machines will be packed in strong wooden crates firstly then place into the containers. The employees are always grave and expert as soon as they are dealing with the containers, ensure our clients could see their products safely.

If you want to get more useful information about our machine .please contact us freely.

contact person :Jeremy

contact mibile:86-15153016158

skype:846319306 @qq.com

We are looking forward to establishing long-term business relationship with you.