professional products safe mini biscuit making line

Product Description

As a full-automatic roller-cutting biscuit production line, it is able to produce all popular biscuits in market such as toughness biscuit, crisp biscuit, butter biscuit, sandwich biscuit, ultrathin biscuit, milk biscuit, soda biscuit, animal biscuit, multi-vitamin biscuit, vegetable biscuit, etc just through the modifications of moulds or technical formulas.

Technological Process

Knead dough→ Pressing & Forming→ Baking→ Oil Spray→Cooling→ Combing→ Packaging

Equipment Configurations

- Dough Mixer: Evenly stir flour alone or starch mixture with a certain amount of water, with a purpose of forming into pastes.

- Pressing & Shaping Machine: This machine consists of pressing part and shaping part. The pressing part has 5 rollers and it is used to enhance the tenacity of paste and press the paste in to required thickness by rolling compaction many times. The shaping part is used to cut the paste in required thickness into required biscuit shape by different dies. The speed of pressing & shaping machine can be adjusted by controller.

- Baking Oven: Drying the semi-products. Biscuits would become crisp and glossy after baking.

- Oil Spray Machine: Spray oil evenly in the surface of biscuit to improve the taste.

- Cooling Machine: Cool biscuits promptly to satisfy the packing requirement.

Characteristics

- The whole production processes can be completed automatically in one time, including material feeding, pressing & shaping, conveyance, water recovery, drying, oil injection, cooling process.

- Different formulas can be provided to products different biscuit with different tastes.

- Hundreds of die modules can be provided to produce various shapes of biscuit.

- Thickness of biscuit can be adjusted freely.

- Pressing & shaping machine, cutting machine and frying machine are all frequency control.

- Cooling conveyor is special designed with oil filtering function.

- Adopt good quality and food-grade stainless steel, which is professional products safe mini biscuit making line service life and neatness.

- Electricity leakage protection & electricity leakage alarm automatically.

- High automation and accurate control system to save labor cost and improve the quality of final products.

Technical Parameters

Model | Output Capacity | Energy Consumption | Net Weight | Length | Supply Voltage |

GYB-170 | 10-30 Kg/h | 18 Kw | 0.7 T | 11×0.5×1.4M | 380V/50Hz |

GYB-225 | 30-50 Kg/h | 18Kw | 1T | 17×0.5×1.4M | |

GYB-250 | 50-70 Kg/h | 40Kw | 1.2T | 19x0.6x1.4M | |

GYB-280 | 100-130 Kg/h | 56Kw | 2.5T | 36x0.6x1.4M | |

GYB-400 | 100-200 Kg/h | 110Kw | 3.5T | 36x0.7x1.4M |

Workers

Normally 1-2 operators are sufficient for production.

Packaging & Shipping

Our Services

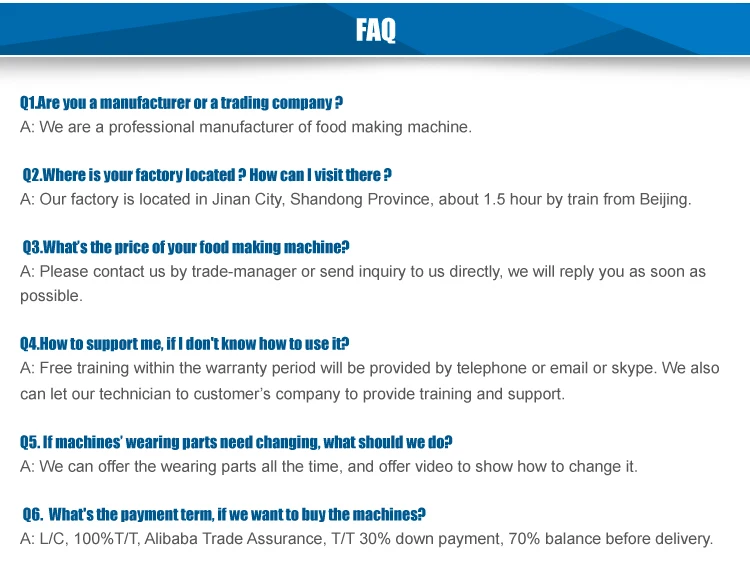

FAQ