1.The parameter of Jinan Saibainuo TSP extrusion processing line:

2. Brief Introduction about Jinan Saibainuo TSP extrusion processing line:

With raw materials of bean pulp and peanut meal, the TVP food processing machine could break and re-systematize the chain of globular proteins with laminar fiber structure by grinding, stirring, tempering, high temperature, high pressure and high shearing process. The final products have the advantages of high nutritive value and meaty shape-taste without cholesterol or animal fat and it can be absorbed by oil, water and flavor, which is able to be applied in many types of fields. Defatted soybean powder, soy protein concentrate or soy isolate protein as the raw material, the textured soybean protein is mainly made through the process of mechanical stirring, extrusion and puffing, with high nutritive value and super-good performance.

3. Raw Materials:

adopts defatted soya flour with oil content below 1%

4. Products:

This line can be used to produce soya nuggets, TVP/TSP, soya chunks by adjusting the moulds from extruder; meanwhile it can produce cereal, snacks by adjusting the screws from extruder.

5.Technological Process:

Raw Materials Configurations→ Mixing→ Conveyance→ Extrusion→ Conveyance→ Drying→ Cooling Conveyance.

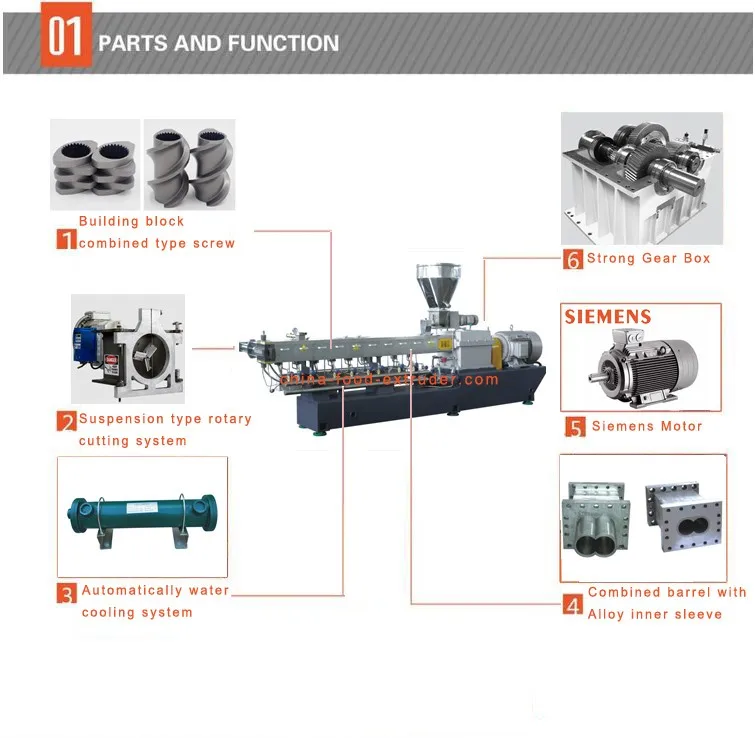

About our twin screw extruder:

Detailed Images

Detailed Images

Certifications

Certifications

Our Service

Our Service

Before sale services:

1).Provide the free consultation of the equipment.

2).Provide the standard device and the flow chart.

3). According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

Services during the sales:

1).Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2).Welcome to visit our factory or the domestic clients’ factory.

3).Inspect the machine before leaving the factory.

After sale services:

1).Oversea install and debug the equipment.

2).Train the first-line operator.

3).Provide the basic formula.

Packaging & Shipping:

1).packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film.Finaly pack them with wooden case.

2)Customer's requirement is available.

3).If you want to know the transportation cost: by air-please tell me your airport name; by express-please tell me your detailed address(including zip code,house number,street,city,country); by ship-pls tell me your delivery port.

Related Products

Related Products

baby food making machine

97.8% Response Rate

cheetos kukures machine

98.9% Response Rate

pasta food production line

99.6% Response Rate