Automatic Textured Soybean Protein Equipment

soy protein production line is the Automatic Textured Soybean Protein Equipment botanical protein food process line which is developed independently according to our national conditions on the requirement of market and on the base of advanced machinery in Switzerland and America.

This processing line uses soybean powder and peanut powder to break spherical protein molecule to form chain protein molecule thus creating slice-like fiber structure, by powder-grinding, stirring, high-temperature, high-pressure and high-cutting .

The product is nutritious without cholesterol or animal fat ,but it looks like and tastes like meat with the quality of absorbing soil ,water ,and flavor

1.This GOOD Textured Soya/Vegetable Protein (TSP/TVP)Food Processing Line use the defatted soya/peanut flour as the raw material.

2. Textured Soya/Vegetable Protein (TSP/TVP)Food Machine's Main feature:

low production cost and high profit.

3.Through this Textured Soya/Vegetable Protein Food Product Machine processing line, the materials can be reorganized and shaped into different shapes such as pipe, stick, ball and more.

4.As this line makes more concentrated and healthy protein, it has become the most popular line in the world

5.The screws are made by alloy steel and special craft, the screw life is Automatic Textured Soybean Protein Equipment, uses building block system structure, may combine willfully

6.The forced lubrication system, by guaranteed equipment transmission Automatic Textured Soybean Protein Equipment lifespan

Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.GOOD Textured Soya/Vegetable Protein (TSP/TVP)Food Processing Line

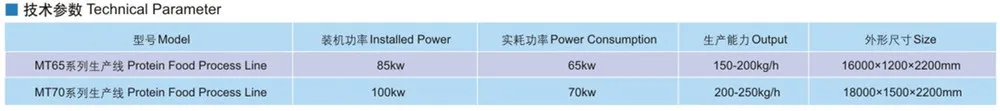

7. Technical Parameters:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If you want to get more detailed information of our machines,pls send inquiry to me.

Formation of soy protein production line:

1 Mixer:There are 3 machine model numbers to choose from base on the production capacity.

2 Conveyor:To convey raw materials to the extruder machine

3 Extruder machine: To choose DSE model extruders base on the production capacity requirement from 100kg per hour to 3ton per hour. The raw material include corn powder, cereal powder, soybean powder, shrimp powder and so on. Shape of the pellet depends on the moulds.

4 Hoister: Convey cheetos to the dryer, the height of the hoister depends on the dryer.

5 Multilayer dryer:Electric dryer, controlled by control box, temperature range 0-200ºC.Inside is stainless steel double layer mesh net. Drying time is adjustable according to speed. We have dryers of 3 layer 5 meter, 5 layer 5 meter, 5 layer 7 meter, 5 layer 8 meter, 7 layer 8 meter, and 5 layer 11 meter steam dryer.

6 Sifter:To remove scrap.

7 Flavoring line: To spray oil and phagostimulant, the equipment are: single roller, double roller, round roller, eight-angle roller. Varies depends on the different production line setting, to spray oil to the surface of the product and make it even.

8 Cooling conveyor: To lower the product temperature in order to pack it easily.

9 Sifter: To remove the wasted material and ensure quality, meanwhile to ensure the reuse of materials.

10 Packing machine: Manual and automatic packing machine.

Product Show

Payment term:30% of total amount by T/T in advance as down payment, we will complete the whole line within 40 days, the rest 70% paid by TT after the buyer test the machine in seller’s factory and before we make delivery.

Package: Wooden case for export, fit for multiple handing and long distance marine shipping.

Delivery time: Seller should get all the goods ready and ship the goods to the destination port within 30 days after receiving the total amount price.

Company Information

MT Machinery Co., Ltd.'s products include double screw, single-screw extrusion machine, automatic continuous frying pot,Automatic Textured Soybean Protein Equipments, pet food production line production line,bugles crescent fish salad production line, nutrition Rice Automatic Textured Soybean Protein Equipment, fried Automatic Textured Soybean Protein Equipment production line production line,spiral shell production line, the dog biting rubber-production line, breakfast cereals, maize production line,tissue protein production line, regenerated rice production equipment, small instant Automatic Textured Soybean Protein Equipment production line. With the industry's senior talent and technology advantages of the elite, and the "pragmatic, innovative, enterprising, honest" business philosophy, "serious, active, rigorous, efficient"style of doing things, to provide high-quality products to customers. Company with strong technical strength, high-quality products, reasonable price, perfect after sale-service, is willing to sincerely cooperate with you, create a better future.

Our Partners

We Provide Satisfied Service & Turnkey Solution

a.) Consultation service before, during, and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas;

g.) Provide 1 year complete warranty and life-time maintenance service.

Why Choose Us

♥ All your inquiry and emails will be replied in 12 Hours

♥ Experienced staffs answer your questions in professional and fAutomatic Textured Soybean Protein Equipmentt English

♥ Factory directly sale

♥ One year warranty and lifetime technical guidance