Features:

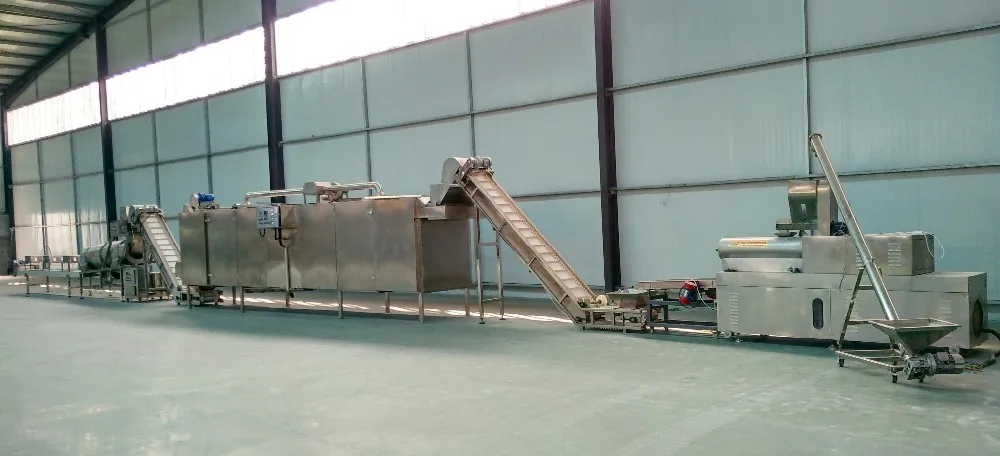

1, soya protein extruder .After protein food is extruded from the dies of extruder, the food is silced into granules, flakes ,chunks,nuggets,goulash, steakettes(schnitzel), et. By revolving knives,and then is dried in a rotary dryer ,

2 soya protein extruder adopts defatted soya flour as raw materials

3. Output can be 160-200kg 240-300kg/h, 500kg/h, 1ton/h

4. Flow chart of Fibre soya protein extruder :Mixing system---Extrusion system--Drying system (Frying System) --Packing system

5.Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz,we can make it according to customers' Local voltage according to different countries.

Assembly Workshop

Our WorkshopShowing Workshop

Show finished machines

Office

Our office

Team

Our Team

Meeting Room

Meeting with customers.

Sample Room

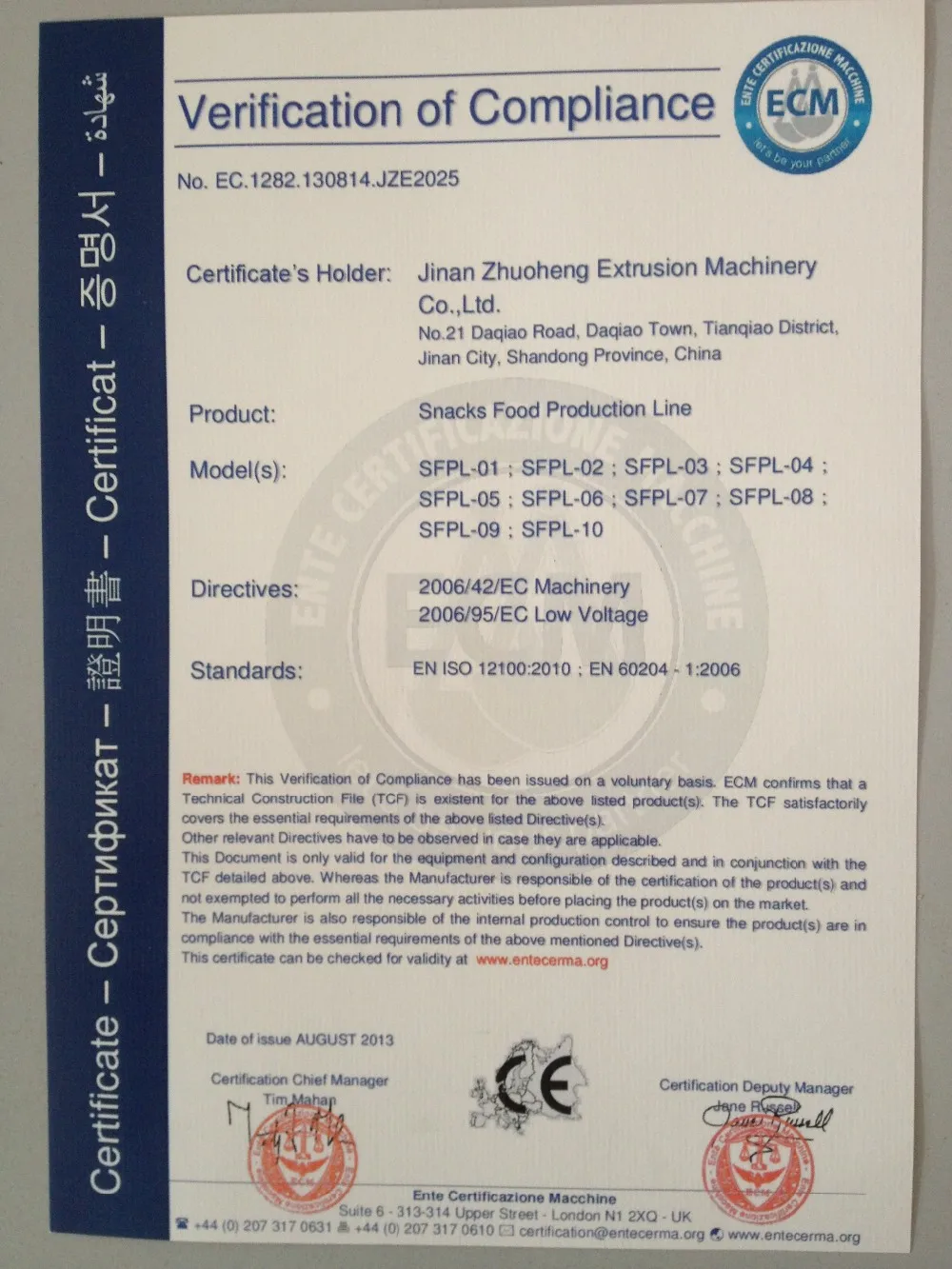

Showing products produced by our machine.Certifications

FAQ

FAQQ1. Are you a manufacturer or a trading company?

A: We are a professional manufacturer of food & feed extrusion machine.

We have own factory and R&D department. SGS has certified our company on site.

Q2. What is your payment terms?

A: Strongly recommend to use textured vegetable soya protein maker’s Trade Assurance.

T/T :30% prepayment,70% before delivery. L/C at sight is available.

Other payment is negotiable

Q3.Do you offer guarantee for the products?

A: Yes, we offer 1-2 years warranty to our products.

Q4. What about the lead time?

A: Regular products:20-30 working days

Customizable products:30-40 working days.Q5. Can you provide food or feed formula ?

A: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.Q6. What after-services do you provide?

A: Send engineers for installation, trial running and training workers at customer's site.

Handling the problems occurred during use. Supply spare and wearing parts on discount.Help customers to solve any other problems .

Packing & Delivery

Packing: Outer Packing---Wooden case

Inner Packing----Wrapped with plastic film.

Delivery : 20-40 working days

1. Fixing the machine2.Wrapping machine with Plastic film3. Wooden case Packing

1. Fixing the machine2.Wrapping machine with Plastic film3. Wooden case Packing

4. Painting Logo5. Loading6. Ready for Shipping

4. Painting Logo5. Loading6. Ready for Shipping