TVP textured fibre soya chunck protein food production line CE certificate

Brief introductions of protein soya chuncks making machines:

Protein extruder adopts the design of combined fuctional screws.The production parameters

can be controlled automatically and accurately. The line adopts low-temperature soybean meal,peanut meal,

wheat gluten etc .The protein extruded producing is strength,toughness .And the shape is various ,it can be

cylinder,flakes,the strips,rounded grain,square grain and so on.

1. Raw Materials: Low-temperature soybean meal,peanut meal,wheat gluten etc

2. Products: All kinds of protein with different shapes and types.

3. Capacity: 100-150KG/H ,200 -450KG/H,400-800 KG/H

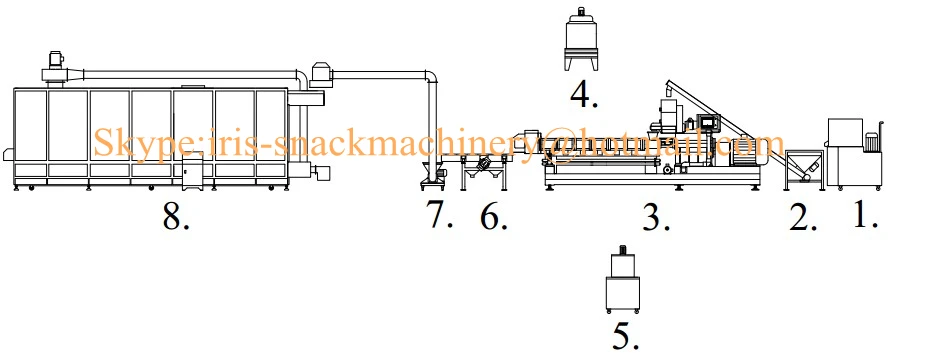

4. Flow Chart: Mixing —Extruding —SpreadingBaking —Drying —Cooling

5.Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ,

also can make it according to customers' local voltage of different countries

6. Machines Materials: All the machines are made by food grade stainless steel.

1.Raw material mixer: to mix varous raw material evenly

2.Screw conveyor : to convey raw material to extrude

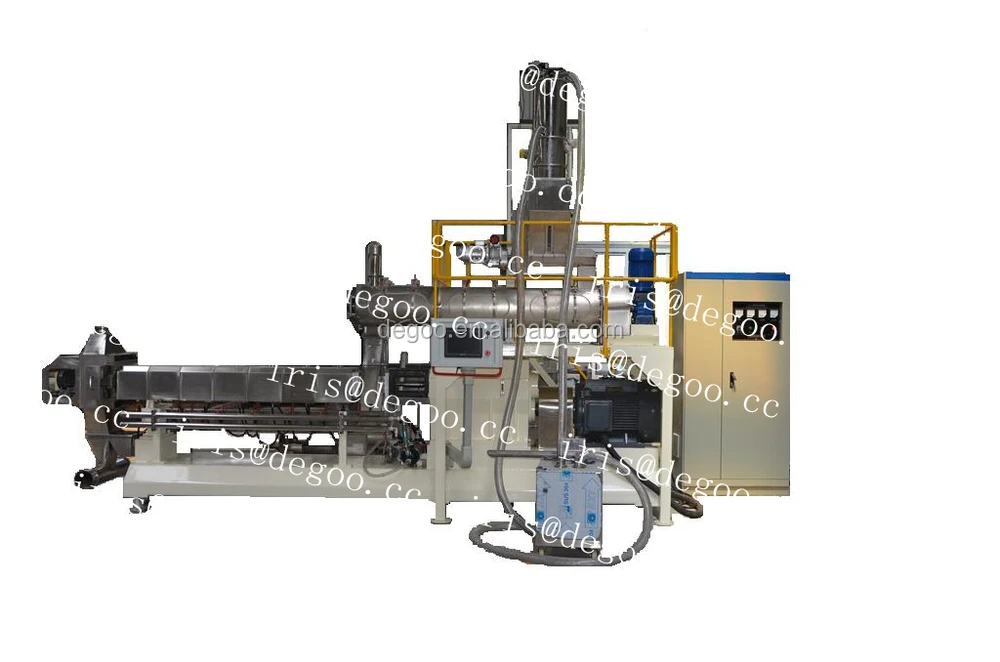

3.Twin/Double screw extruder :to extruder and cook the raw material into different shapes protein

4.Water cooling tower: to supply cooling water in the processing process

5.Water injector: to inject water on the producing process.

6.Vibrating cooler: to spread the products and cool it quickly.

7.Air conveyor: to convey the food to the next machine

8.Belt drying oven: to dry snacks food by circulating belt.

Technical Parameters of textured soya protein processing line:

| Model | Installed powder | Power consumption | Throughput | Dimension | Product |

| DG52-II | 91KW | 68KW | 100-150KG/H | 19.8X2.7M | Textured/fibre protein |

| DG70-I | 186KW | 140KW | 200-450KG/H | 22X3.2X3.1M | Textured/fibre protein |

| DG90-I | 185KW | 139KW | 400-800KG/H | 25X3X3.1M | Textured protein |

Food samples of textured protein/fibre protein:

News designs machinery of TVP(TSP) soya protein chuncks /artificial meat processing line :

Our Service & Turnkey Solution

1.Consult service before,during and after-sale.

2.Production line planning and design .

3.Factory lay out planning .

4. Debugging of equipments until producing products and everything is normal.

5.New production techniques and formulars.

6.Supply with 12 months wanttery and life-time maintenance .

We are realiable corn flakes machienries manufacturer with CE ISO CIQ certificate:

Packaging and shipping:

Special starff to caculate and design containes space to use less space accomate more equipments

Equipments demonstrating and producing workshop:

Warmly welcome to our factory at any time to check it

About us :Tissue protein /textured protein production line 500kg/h with CE ISO certificated machinery co.,ltd in China:

We: Tissue protein /textured protein production line 500kg/h with CE ISO certificated machinery co.,ltd located in Jinan ,Shandong Province ,China, is the professional manufacturer of

Tissue protein /textured protein production line 500kg/h with CE ISO certificated processing machinery.We specialize in this field for may years ,not only can supply with the entire machiner

design,but also can modify the production line to meet client's demand.All kinds of patents , proprietary technology ,

breakthrough and certificated .

There is a testing center in our factory which combined experiments,dmonstration andtrainingin one facility.We also

can test new technical experiments according to customer requirements .

Our extrusion systems are widely used in:puffed Tissue protein /textured protein production line 500kg/h with CE ISO certificated,breakfast cereals,corn flakes ,nutritional artificaila rice,

textured or fibre protein food,pet food,aquatic feed,modified starch,bread crumbs and other Tissue protein /textured protein production line 500kg/h with CE ISO certificated.

If you are interested in us,pls no hestitate to contact us: