latest middle scale frid instant noodels machine

Introduction (application)

Instant Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines production line is used to fully automatically produce ripple-type instant Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines with high automaticity, easy operation, moderate output, good energy conservation and small floor space.

Technological Process

Raw Materials Configuration→ Mixing→ Pressing & Shaping→ Cooking→ Cutting→ Frying→ Cooling & Oil Filtering

Characteristics

- The size of instant Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines can be adjusted according to users’ requirement.

- Pressing & shaping machine, cutting machine and frying machine are all frequency control.

- Rolling pressing design make the Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines more springy.

- Adopt good quality and food-grade stainless steel, which is Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines service life and neatness.

- Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines frying length to ensure good cooking and better taste of instant Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines.

- Cooling conveyor is special designed with oil filtering function.

- High automation and accurate control system to save labor cost and improve the quality of final products.

Technical Parameters

Output Capacity | Model | Type | Workshop Size (M) | Workers |

11000 pcs | GYN/F-210/1 | Fried | L22*W4*H3.5 | 2~4 |

GYN/N-210/1 | Non-fried | L33*W4*H3.5 | 2~4 | |

20000 pcs | GYN/F-210/2 | Fried | L27*W4*H3.5 | 2~4 |

GYN/N-210/2 | Non-fried | L38*W4*H3.5 | 2~4 | |

Note: | 1. The output capacity is calculated according to 8 working hours. In actual production, factory usually works 24 hours per day continually and stop for maintenance regularly. 2. The shape of lump instant Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines can be quadrate or round. We shall quote you and design the production line according to users’ detailed requirements. 3. We can shorten the required workshop size by turning. 4. The required workshop size and workers is calculated according to the production line without packaging line. | |||

Workers:

Normally 1-2 operators are sufficient for production.

Samples

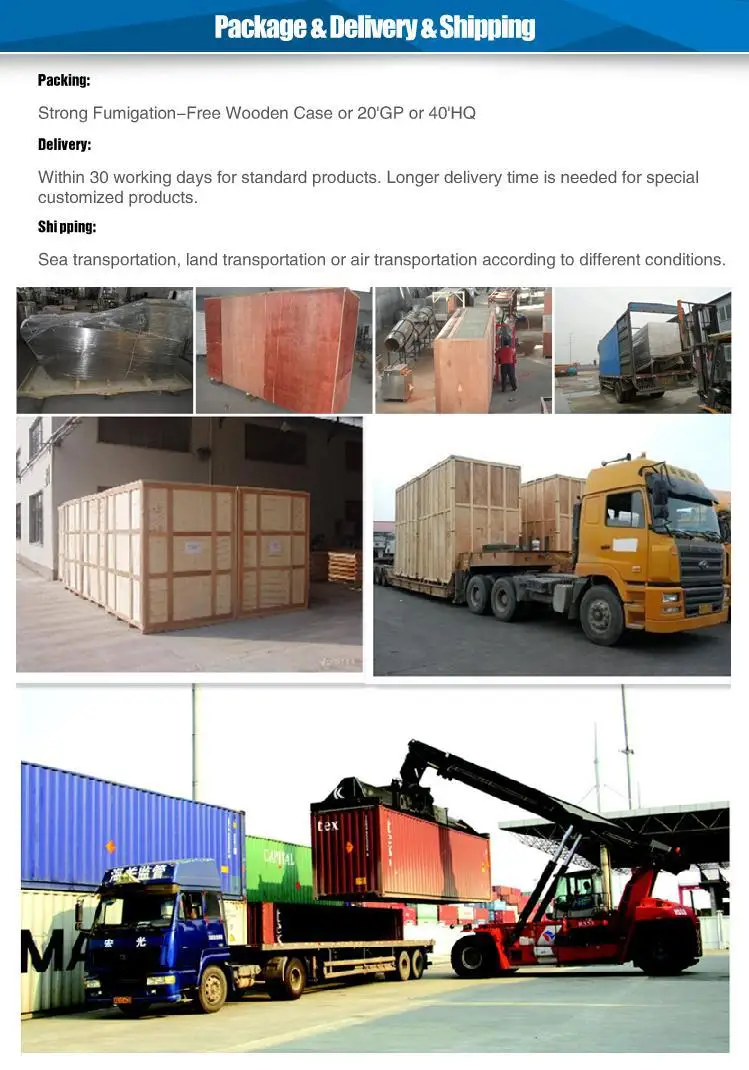

Packaging & Shipping

Our Services

Company Information

Jinan Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines Machinery & Equipment Co., Ltd.(GY Machinery)is the professional manufacturer for advanced and high-quality food machinery.

GY has an expert team with around 15 years experiences in food machine industry. We constantly research extrusion technology and explore food process in order to benefit our clients producing better and creative food.

After years of research, GY has different production lines with different output capacities to meet different customer requirements:

1. Direct Puff Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines Process Line

2. Breakfast Cereal & Corn Flakes Process Line

3. Core-Filling Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines Process Line

4. 2D Pellet Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines Process Line

5. 3D Pellet Fried Wavy Instant Noodle Production Line|Instant Noodle Making Machines Process Line

6. Cheetos/Kurkure/ (Nik) Naks/Corn Curls Process Line

7. Triangle Chips/ Doritos/Tortilla Chips/Pringles Potato Chips Process Line

8. Fried Wheat Flour Snacks/Salad/ Crispy Chips/Bugles/Rice Crust Process Line

9. Natural Potato Chips / Crisps / French Fries Process Line

10. Pasta/Macaroni Process Line

11. Nutritional Rice/ Artificial Rice Process Line

12. Nutritional Powder/Baby Food Process Line

Modified Starch Process Line

13. Bread Crumb Process Line

14. TVP/TSP/Soya Protein Process Line

15. Pet Food/ Dog Food/ Cat Food/ Fish Food Process Line

16. Biscuit Process Line

17. Instant Noodle Process Line

18. Meat / Seafood/ Vegetable Fast Food Process Line

Burger Patty/ Chicken Nuggets/ Chicken Popcorn/ Fish Fillet Process Line

Our Customer

Components & parts

FAQ

Contact