Product Description

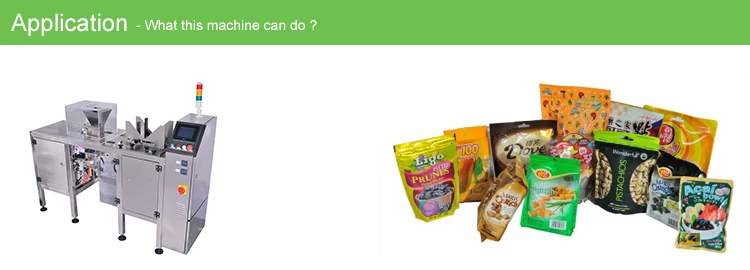

High quality Liner Type moringa powder packing machine is applicable for dosing powder, granule or liquid into a premade pouch and sealing, the detail application description as following table:

Issue | Application Description |

Applicable Pouches | Laminate heat sealable pre-made pouches like flat pouch , gusset pouch, normal stand up pouch, or stand up pouch with zipper etc |

Applicable Products | Configure with different dosing devices, capable to pack with liquid, powder granule, or other irregular solidity materials. |

Applicable Packaging Material | Laminate Heat sealable packing materials such as OPP/PE,BOPP/OPP/PE,PET/AL etc |

Standard Features

• Heat sealable premade flat pouch dosing and sealing

• PLC & HMI Control , Easy for parameter setting and troubleshooting

• Different pouch size adaption, simple adjustment without tools

• Intelligent temperature controlling configuration, ensure the artistic and neat sealing.

• Pouch saving design, no completely opened pouch, no filling and sealing.

• Compatible Programs of powder, granule or liquid dosing, plug and play, easy for different products switching

• Machine stopping interlock with door opening

Optional Features

• Pouch zipper opening function

• Gusset pouch opening function

• Vibrating product dosing function which apply for product without good fluidity

• Vibrating compacting function which enhance packaging density

• Air/Nitrogen Inflating, Air deflating function

• De-dusting device to enable clean packaging environment and ensure quality of sealing

• Different types of code printing function

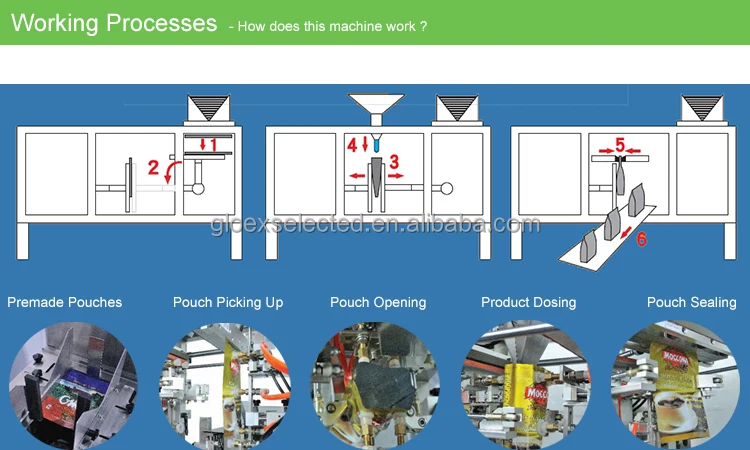

The working processes include: pick up the premade pouches from the magazine and feed for opening, pouch opening, products dosing and pouch sealing. Upon the different products, we need to configure specific process like zipper opening, air/nitrogen inflating, air deflating. Product vibrated feeding or setting etc. above are the typical working process diagram

Catalogue/1R-xxxxx | 300 | 430 | Duplex |

Work Stations | 1 | 1 | 2 |

Pouch Size-Length ‘mm | 100-300 | 100-430 | 100-300 |

Pouch Size-Width ‘mm | 100-300 | 100-300 | 100-200 |

Packing Speed –pouches/min | 5-15 | 5-15 | 10-30 |

Reference Filling Range-g/pouch | 5-1500 | 5-2500 | 5-1000 |

Power Requirement | AC220V 50/60HZ | AC220V 50/60HZ | AC220V 50/60HZ |

Power Consumption-KW | 1.5 | 1.5 | 1.5 |

Compress Air Required-Mpa | 0.65 | 0.65 | 0.65 |

Compress Air Consumption-m3/min | 0.5 | 0.5 | 0.5 |

Dimension ( ‘mm ) | 1750*510*1300 | 1750*510*1650 | 1750*750*1450 |

Note: the width of the pouch shall not less than 130mm if apply for zipper pouch

Practically, beside this liner type premade pouch packaging machine, the rotary type machine is also the premade pouch packaging solution. But compare to rotary type machine, this liner type machine has its advantages as indicated in the following table:

No | Issue | Advantage |

1 | Dimension | More smaller size of the machine and system, less space requirement |

2 | Maintenance | Simple liner process design other than 6/8 rotary workstations, less maintenance |

3 | Stability | Simple design, less component and process, enable more stable operation |

4 | Price | 1/2-2/3 price of rotary type machine/system |

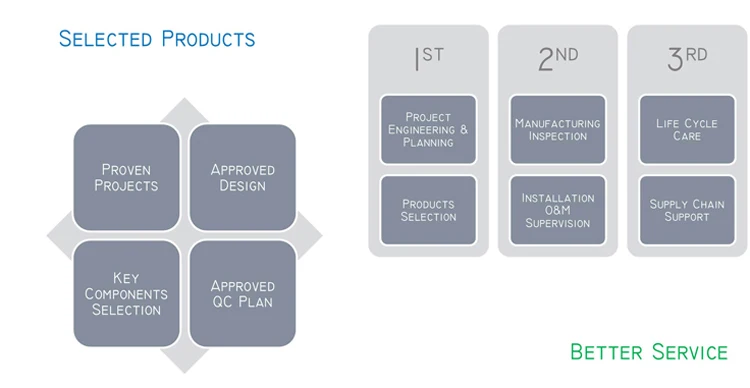

Except for the engineering of the machine, the key components configuration will determine the quality of the machine or system, below is the standard configuration of the key components:

No | Issue | Material / Brand |

1 | Products Touching Parts | Stainless Steel 304 |

2 | Structure & Surface | Stainless Steel 304 |

3 | Human-Machine Interface | Delta |

5 | Programmable Logic Controller | Mitsubishi |

7 | Temperature Controller | Omron |

8 | Pneumatic Components | Airtac |

9 | Linear Type chips snack packing machine Components | PIAB |

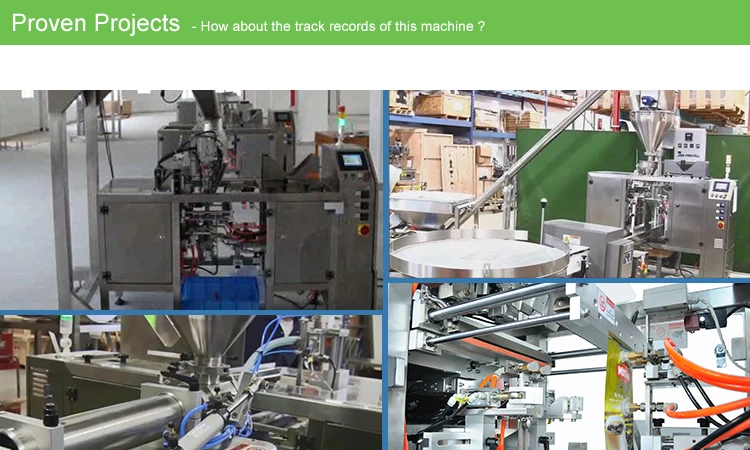

This above premade pouch packaging machine, with CE approval, running at hundreds of proven projects, stable operation under excellent performance

Related Products

If you think the above machine can't fulfill your requirement , please click the following link to get more machine demostration, like:

Weighing and Packaging Integrated Automatic Pouch Packaging Machine

Single Station Big Bag Premade Pouch Packaging Machine Double Lanes High Speed Premade Pouch Packaging Machine

Documentation

In order to enable you understand our products conveniently, following documents are available, but not limited, to be provided upon the stage of purchasing

No | Document | Code | Description |

1 | Products Selection Guide | SG | To select or customize the suitable products for the clients upon the feedback of Selection Guide, which include project background, parameters and other client’s requirement |

2 | Products Profile | PP | To enable the clients understand the overview of the products, Covers sections of Basic Features, Application, Construction, Typical Products, Approvals, and Optional Features |

3 | Installation Instruction | IN | To explain the step of installation of the equipment, and include commissioning instruction as well |

4 | User Manual | UM | To cover the content of Operation & Maintenance and Trouble Shooting |

Our Services

Customization

Customization Philosophy

The product demonstrating may not perfectly meet your requirements, our philosophy is to customize your real need, To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

- Products to be packed

- Type of pouch to be used , flat, gusset , or stand up pouch and its specification.

- Packing volume per pouch, ml or gram per pouch

- Capacity requirement, namely how many pouches per hour

- Automation requirement

- Protection requirement, details refer to the optional features above

- Other specific requirement

Selection Guide

Selection Guides are available for circulation, contact us to get products selection and customization support.

Statement

- The pictures demonstrating in this profile represent products of range, and subject to the Linear Type chips snack packing machine or customized design

- Due to the huge number of documentation updating, the data indicated in this profile may not be updated timely, Please contact with our customer service for Linear Type chips snack packing machine version.

- The features or functions appear in this profile subject to the additional description of quotation